Device and method for recycling heavy metals in electroplating sludge by using bioleaching coupling electrode electrodialysis technology

A technology of biological leaching and coupling electrodes, applied in the direction of improving process efficiency, can solve the problems of insufficient optimization of reaction parameters, long running time, low efficiency, etc., and achieve the effect of realizing migration, improving treatment effect and reducing sedimentation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

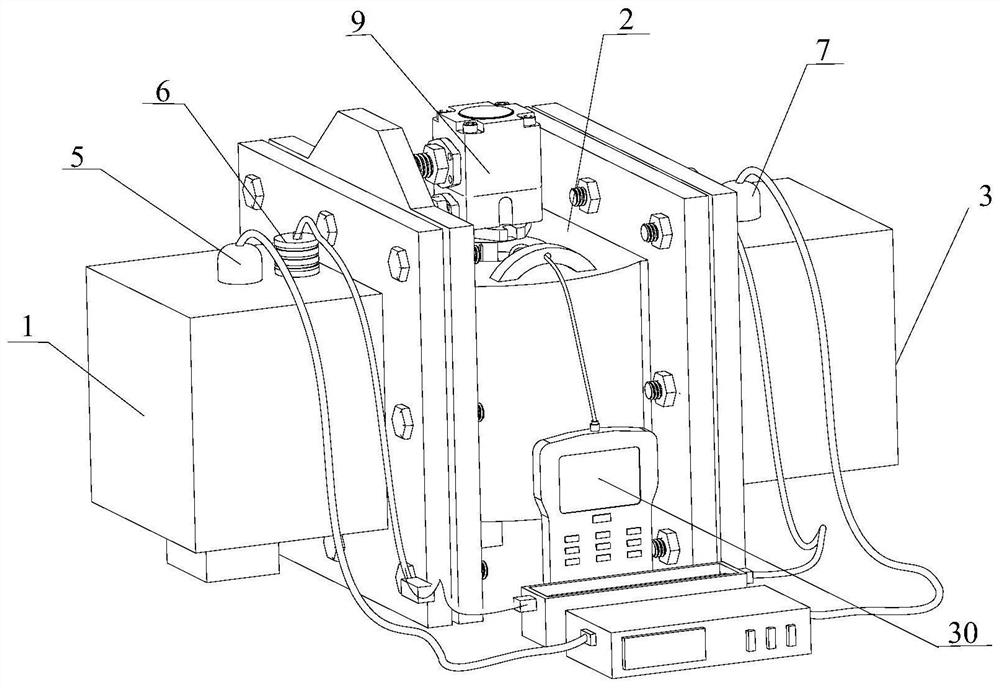

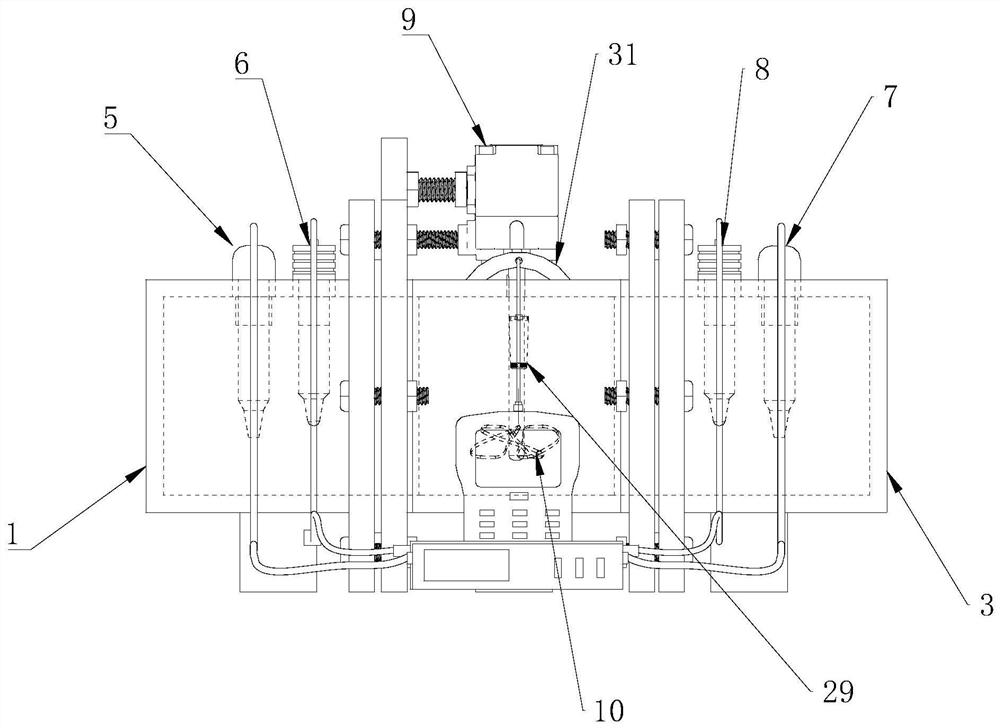

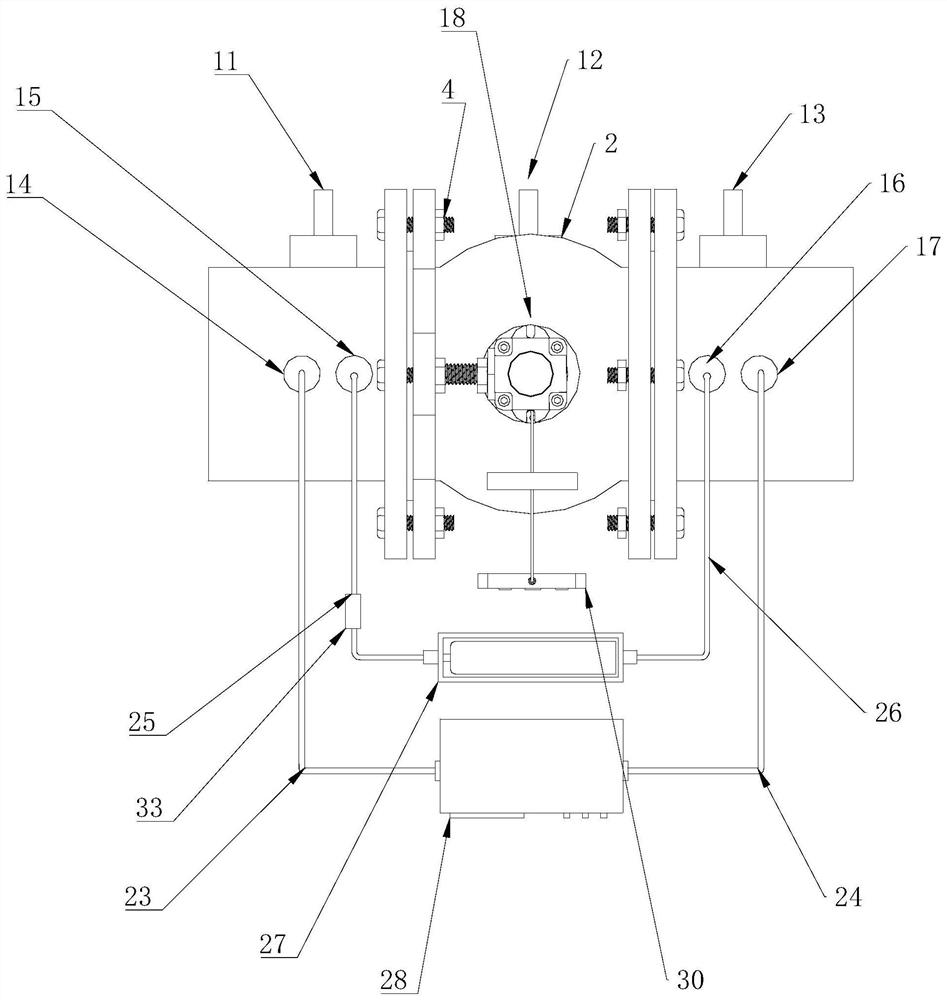

[0037] The device for recovering heavy metals in electroplating sludge using bioleaching coupled electrode electrodialysis technology of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0038] Such as Figure 1~5As shown, the present invention utilizes bioleaching coupled electrode electrodialysis technology to reclaim the device of heavy metals in electroplating sludge, comprising: cathode chamber 1 and anode chamber 3;

[0039] A bioleaching chamber 2 arranged between the cathode chamber 1 and the anode chamber 3, the bioleaching chamber 2 is provided with a stirring paddle 10 and a pH measurement sensing probe 29;

[0040] The first reference electrode 5 and the cathode electrode 6 are arranged in the cathode chamber 1;

[0041] The second reference electrode 7 and the anode electrode 8 are arranged in the anode chamber 3;

[0042] The first reference electrode 5 and the second reference electrode 7 are conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com