Controlled-release fertilizer and application thereof

A technology of fertilizers and fertilizer sticks, applied in controlled-release fertilizers and its application fields, can solve problems such as not being able to meet the needs of nutrient absorption depth, and achieve good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

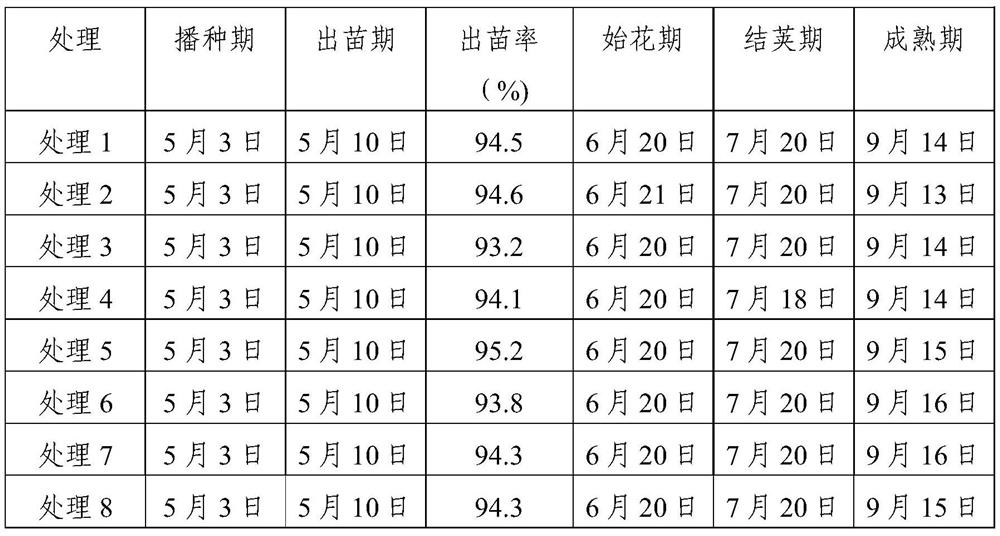

Embodiment 1

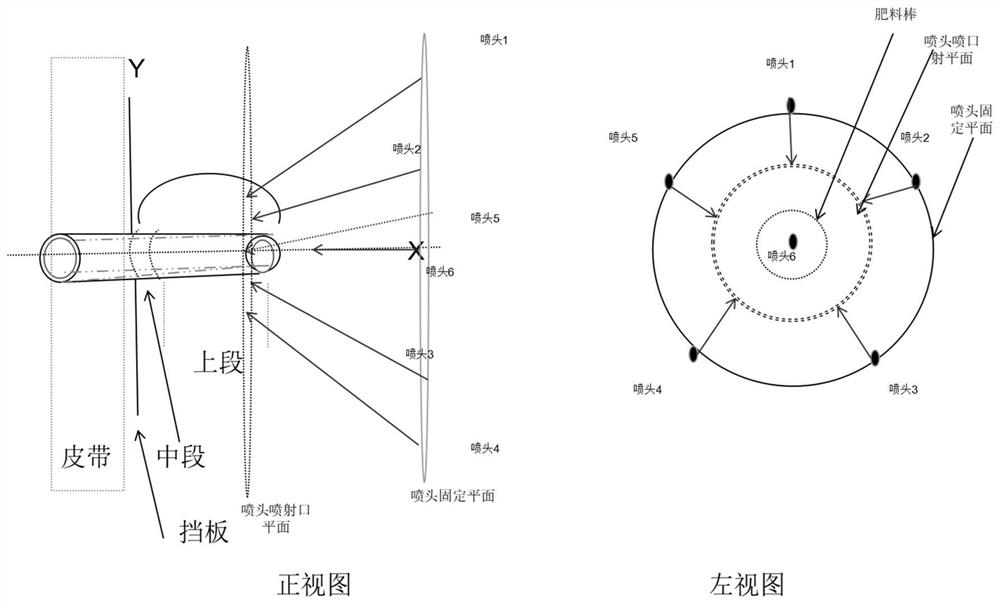

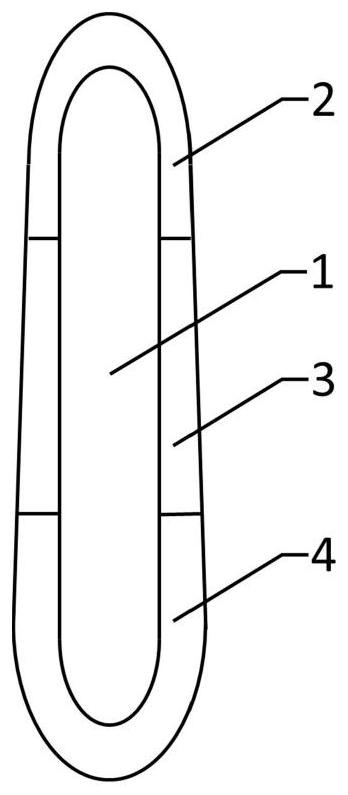

[0051] Step 1: In parts by weight, 5.12 parts of calcium ammonium nitrate, 5.12 parts of ammonium sulfate, 13.74 parts of monoammonium phosphate, 20.61 parts of potassium sulfate, 55.08 parts of dolomite powder, and 0.32 parts of ferrous sulfate are fully mixed through a mixer, and the The press is compressed into a rod shape, and the size control diameter is 1 cm, and the length is 12 cm to obtain a fertilizer rod.

[0052] Step 2: In parts by weight, mix 61.52 parts of urea, 31.32 parts of monoammonium phosphate, 3.13 parts of zinc sulfate monohydrate, 3.13 parts of boric acid, 0.22 part of ammonium heptamolybdate, and 0.67 part of mineral source potassium fulvic acid into the melting tank. Heat to 120°C-130°C and stir to form a uniform slurry.

[0053] Step 3: In parts by weight, dissolve 48.67 parts of urea in an aqueous solution, add potassium hydroxide to adjust the pH to 7.5, heat to 50°C, and keep it stable, add 51.33 parts of formaldehyde solution to react, after 0.5 ...

Embodiment 2

[0061] Step 1-2 is the same as embodiment 1, step 3 adds formaldehyde and reacts for 1 hour.

Embodiment 3

[0063] Step 1-2 is the same as embodiment 1, and step 3 adds formaldehyde and reacts for 3 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com