Laminating and cooling device for waterproof roll

A cooling device and waterproof membrane technology, which is applied in lamination devices, winding strips, transportation and packaging, etc., can solve the problems that the surface of the membrane material affects the cooling effect, the impact of uneven covering pressure, and the lack of winding effect, etc. , to achieve the effect of ensuring the stability of cleaning cache, ensuring the cleanliness of cleaning, and ensuring the stability of cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

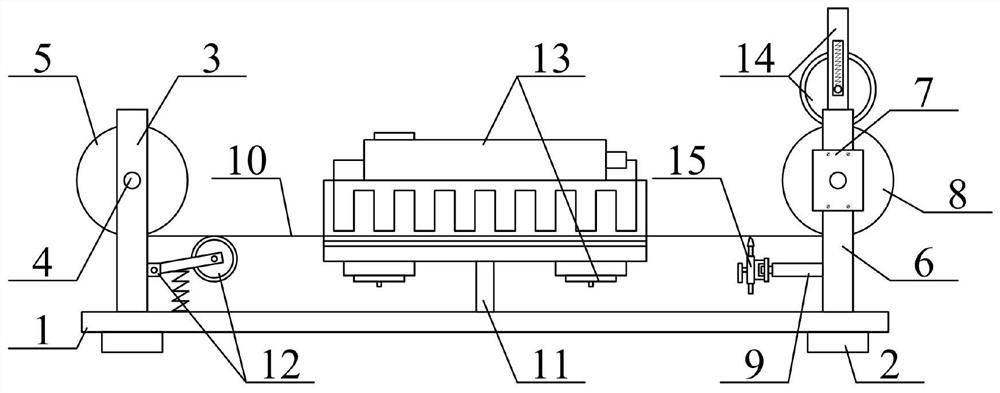

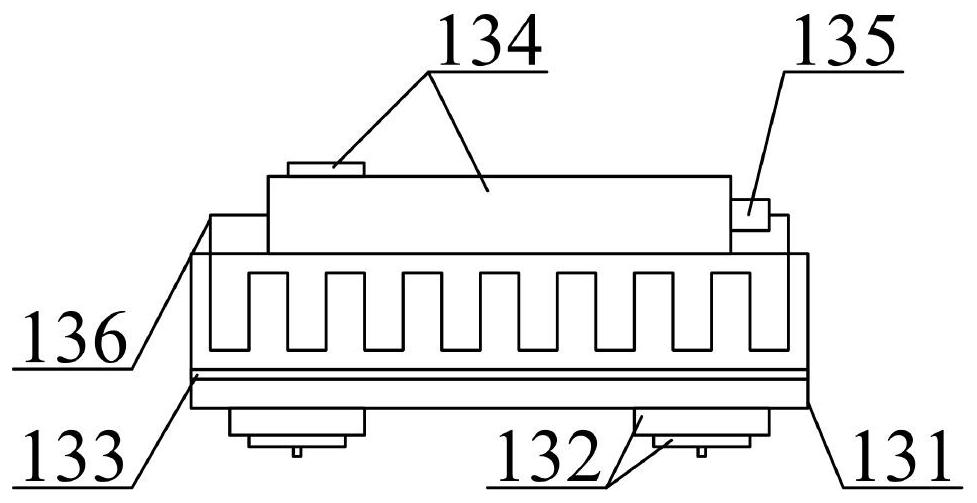

[0034] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2As shown, a film-coated cooling device for waterproof coils includes a machine base 1, a pad 2, an unwinding frame 3, a wheel shaft 4, an unwinding roller 5, a winding frame 6, and a winding motor 7. Rewinding wheel 8, support seat 9, film material body 10, support stand 11, buffer film material surface dust cleaning wheel structure 12, film material cooling back cooling box structure 13, buffer film material rewinding and pressing wheel structure 14 and an adjustable movable cutter structure 15, the four corners of the bottom of the base 1 are bolt-connected with pads 2; the upper left side of the base 1 is bolt-connected with the longitudinally arranged unwinding frame 3 The upper bearing in the inside of the unwinding frame 3 is connected with the wheel shaft 4; the outer wall of the wheel shaft 4 is connected with the unwinding rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com