Novel bulletproof structure and manufacturing process

A manufacturing process and a new type of technology, applied in the field of new bulletproof structures and manufacturing processes, can solve the problems of not exerting the characteristics of shear thickening fluid energy absorption and energy consumption, etc., to achieve enhanced bulletproof performance, reduce impact force and pain , enhance the effect of bulletproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

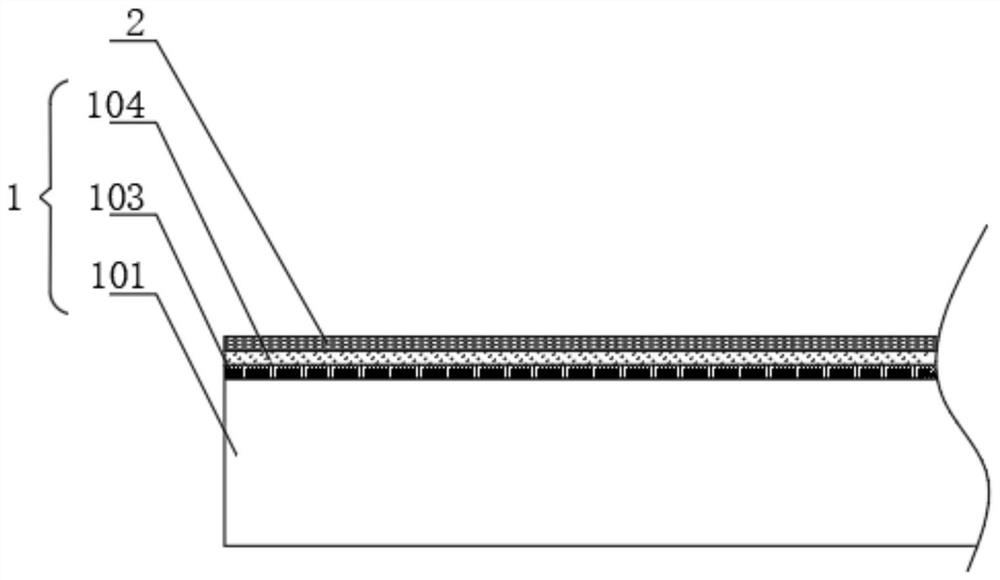

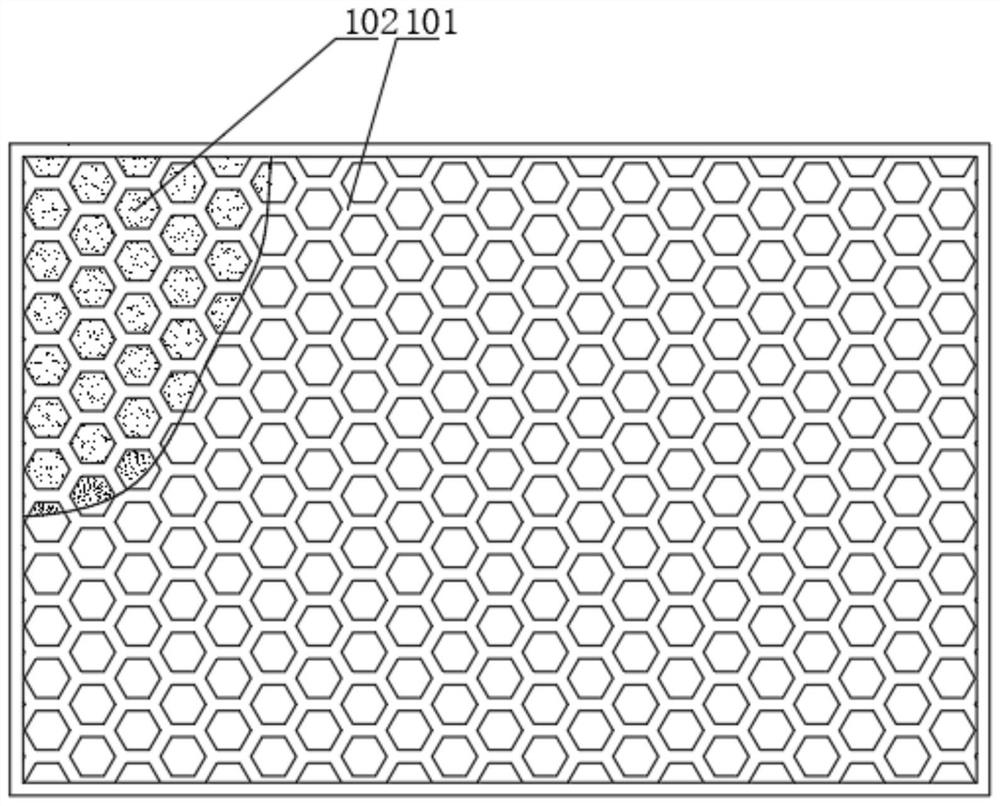

[0030] Such as Figure 1-Figure 3 As shown, the novel bulletproof structure of this embodiment includes a base 1 and an upper cover plate 2, the base 1 includes a honeycomb cavity 101, a shear thickening liquid 102 filled in the honeycomb cavity 101; fiber is laid on the honeycomb cavity 101 The cloth 103 and the reinforcement board 104 are placed on the fiber cloth 103, and the upper cover 2 and the reinforcement board 104 are bonded and fixed.

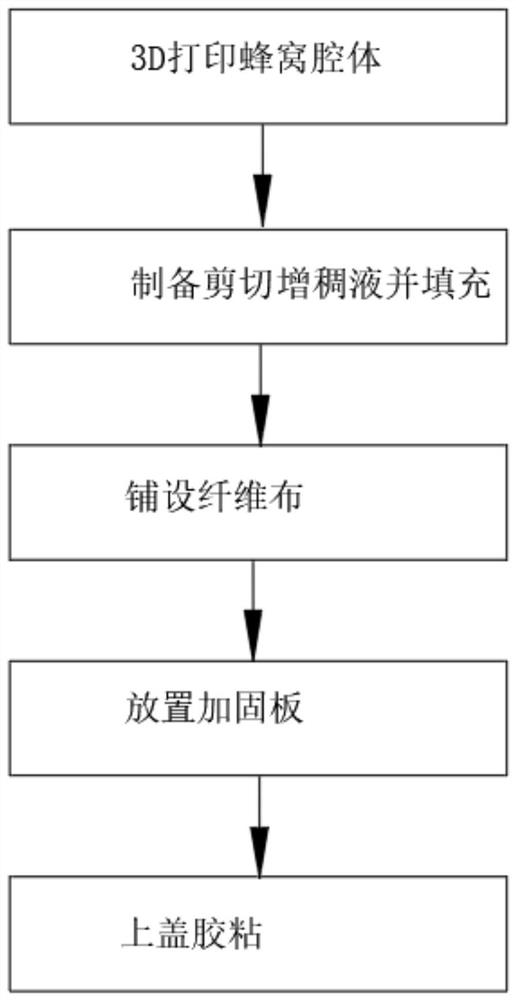

[0031] The manufacturing process of preparing the bulletproof structure of claim 1 of the present embodiment comprises the following steps:

[0032] 1. Prepare the base 1: print the honeycomb cavity 101 by a 3D printer; fill the honeycomb cavity 101 with a shear thickening liquid 102, lay a fiber cloth 103 on the honeycomb cavity 101 filled with the thickening liquid, and lay the fiber cloth 103...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com