Viscosity-controllable abrasive particle flow polishing method and device

A polishing device and abrasive flow technology, applied in the field of ultra-precision polishing, can solve problems such as difficulty in adapting to polishing accuracy and difficult and efficient ultra-precision polishing of rotary parts, so as to improve polishing accuracy and efficiency, reduce processing damage layer, and reduce processing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

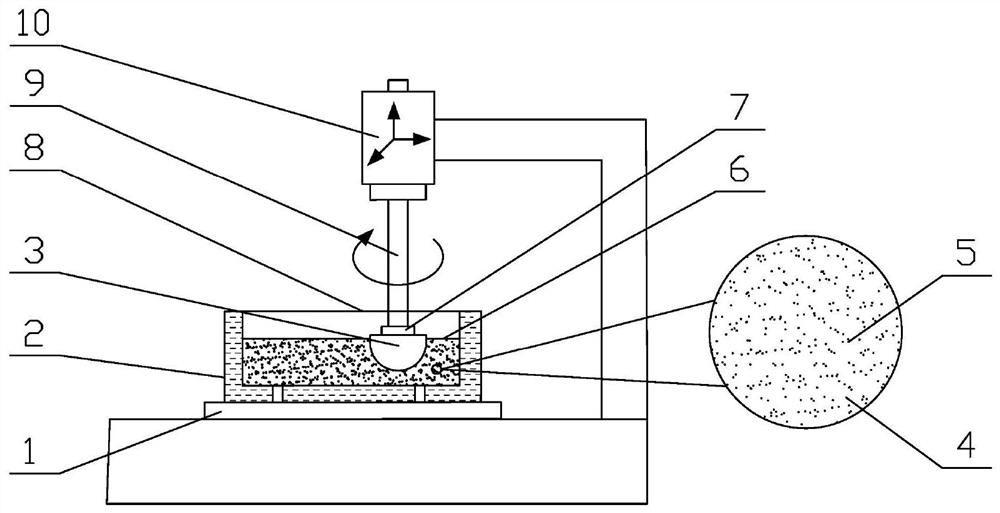

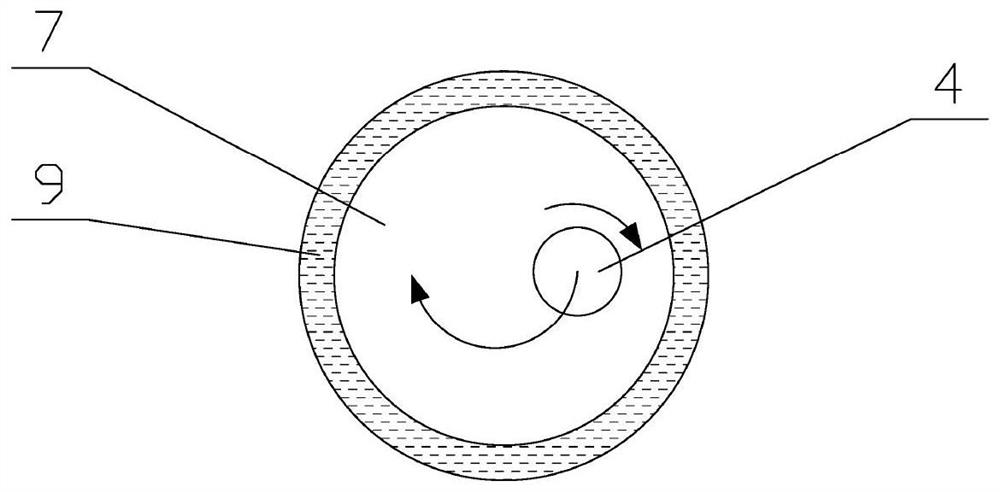

[0020] The solution of the present invention will be further described below in conjunction with the accompanying drawings.

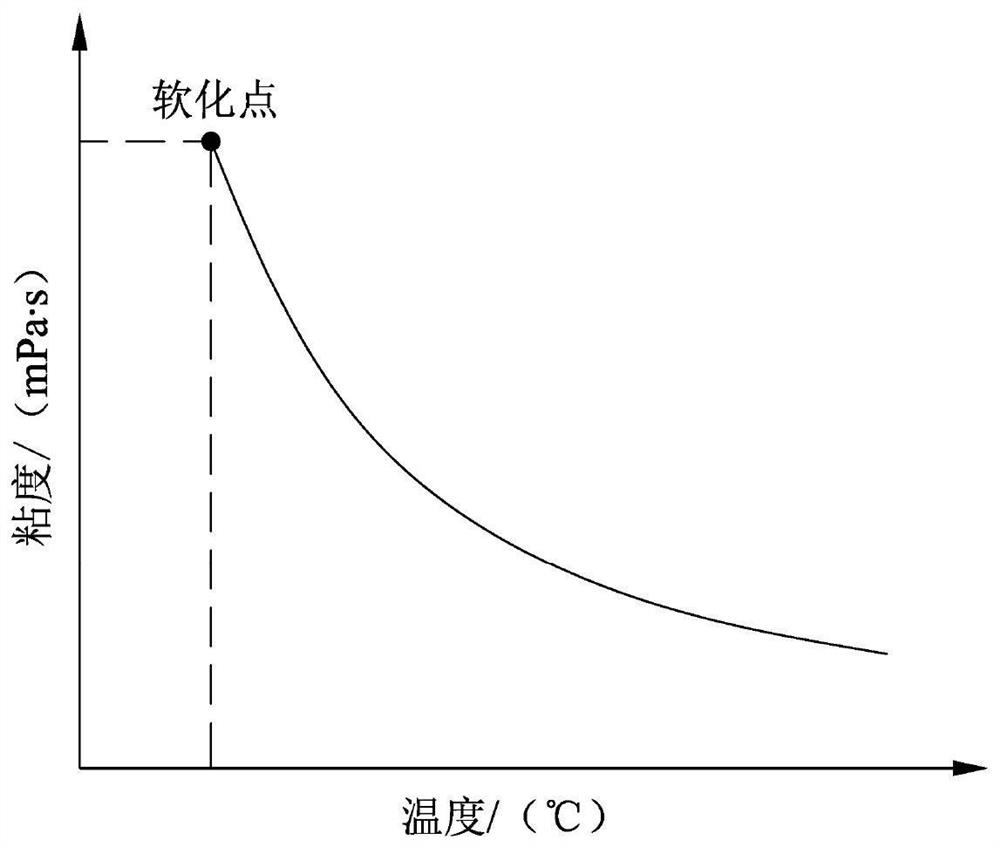

[0021] refer to figure 1 , figure 2 and image 3 , a viscosity-controllable abrasive flow polishing method, mixing solid paraffin and liquid paraffin, heating and melting, adding polishing abrasive grains 2 and additives into the melted paraffin wax mixture liquid 1, stirring thoroughly and uniformly cooling to form abrasive grains 2 The paraffin wax for polishing is solid, and the softening temperature of the paraffin wax for polishing after modification is 30-50°C. Wherein, the mass percentage of solid paraffin is 50-90%, and the mass percentage of liquid paraffin is 0-20%. Before polishing, first use a temperature regulator to heat the solid paraffin wax for polishing to the softening point to form a polishing slime 3; The viscosity of the polishing slime 3 can further change the holding force of the abrasive grains 2 in the polishing slime 3, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com