A radiation unit matching block positioning mechanism, assembling device and method

A radiation unit and assembly device technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of difficult to reach into the radiation unit cavity, narrow operating space, difficult assembly of matching blocks, etc., and achieve the guaranteed distance size. Accuracy, improving assembly qualification rate, and solving the effect of precise installation and positioning problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

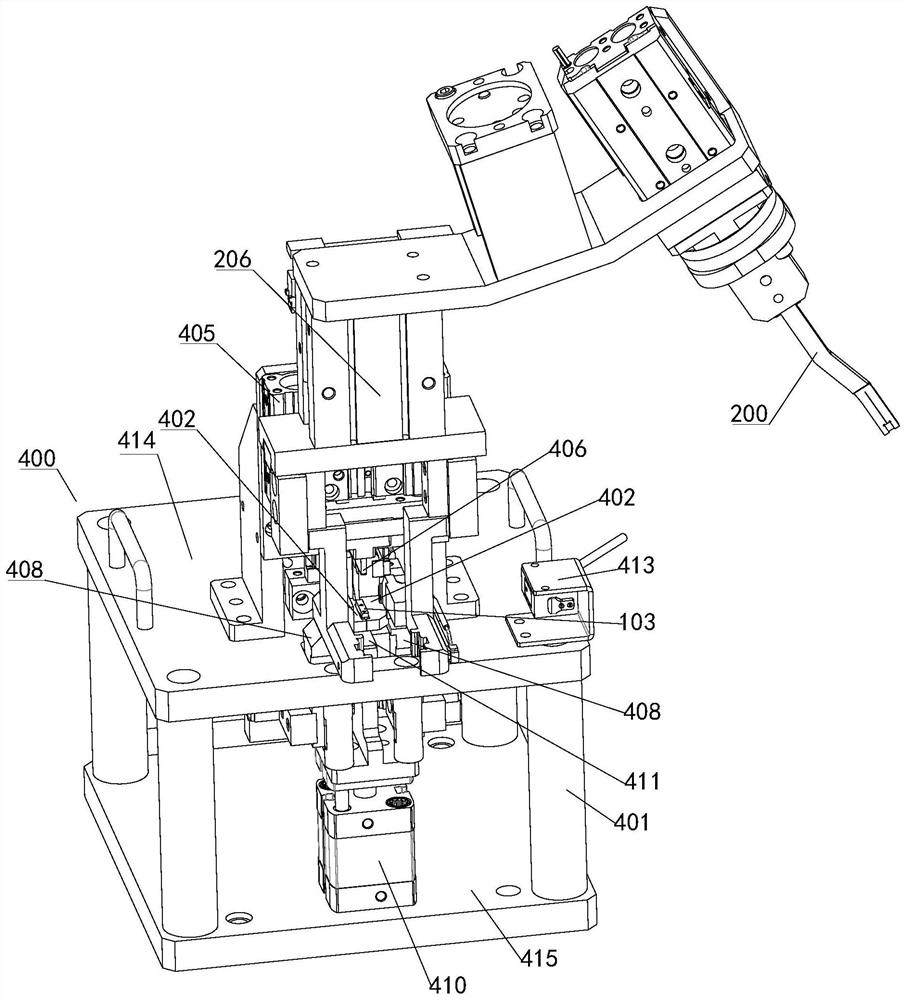

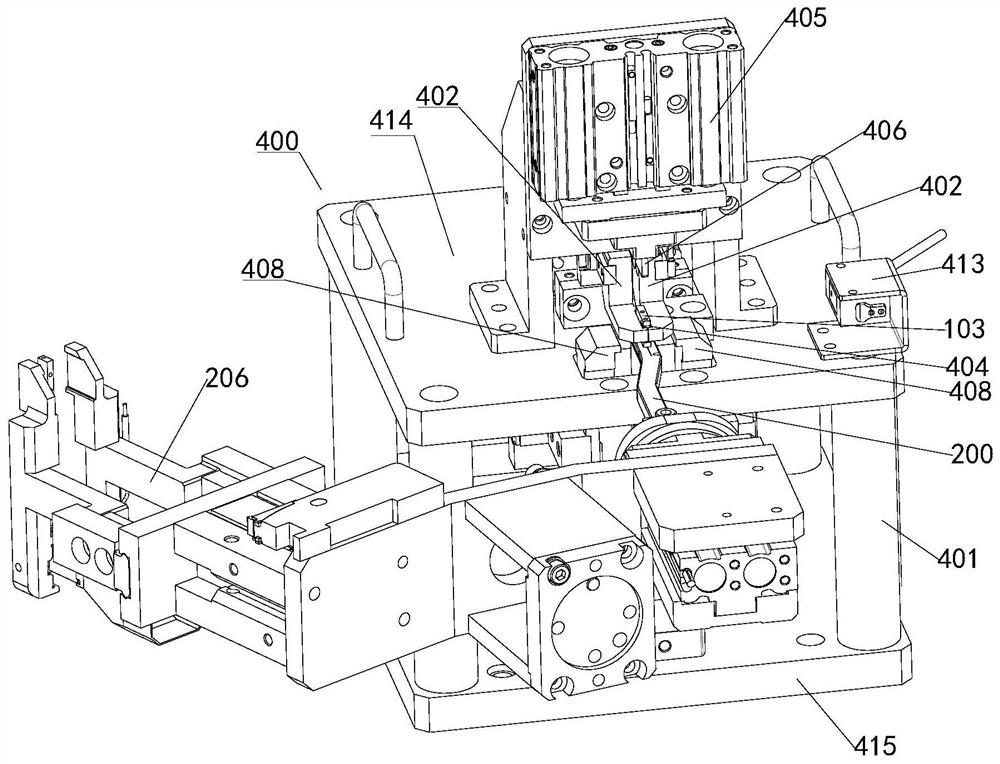

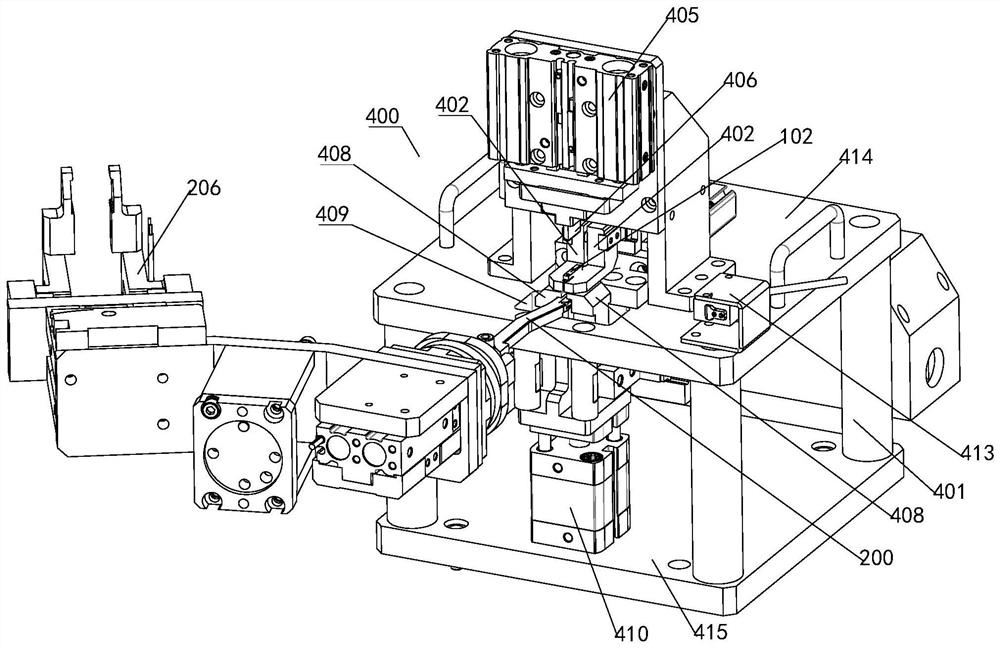

[0053] like Figure 1-Figure 6 As shown, a radiation unit matching block positioning mechanism in this embodiment includes a tooling frame 401 , a first clamping cylinder 402 and a first pneumatic clamping jaw 403 , and the first clamping cylinder 402 is installed on the tooling frame 401 and its driving end is connected to and drives two first pneumatic clamping jaws 403 to open and close. After the claws 403 are closed, a matching block holding hole 404 for holding the matching block 102 is formed.

[0054] In this embodiment, the first clamping cylinder 403 is used to drive the first pneumatic clamping jaw 402 to clamp the matching block 102, and when the clamping block 102 extends into the space between the upper part of the tooling frame 401 and the first pneumatic clamping jaw 402, The first clamping cylinder 403 drives the first pneumatic clamping jaw 402 to release the matching block 102 , so that the matching block 102 falls into the matching block limiting groove 20...

Embodiment 2

[0056] like Figure 1-Figure 6 As shown, a radiation unit matching block positioning mechanism in this embodiment includes a tooling frame 401 , a first clamping cylinder 402 and a first pneumatic clamping jaw 403 , and the first clamping cylinder 402 is installed on the tooling frame 401 and its driving end is connected to and drives two first pneumatic clamping jaws 403 to open and close. After the claws 403 are closed, a matching block holding hole 404 for holding the matching block 102 is formed.

[0057] In this embodiment, the first clamping cylinder 403 is used to drive the first pneumatic clamping jaw 402 to clamp the matching block 102, and when the clamping block 102 extends into the space between the upper part of the tooling frame 401 and the first pneumatic clamping jaw 402, The first clamping cylinder 403 drives the first pneumatic clamping jaw 402 to release the matching block 102 , so that the matching block 102 falls into the matching block limiting groove 20...

Embodiment 3

[0067] like Figure 13 As shown, a radiation unit matching block assembling device in this embodiment includes a matching block fixture 200, an assembling jaw 206, a radiation unit fixture 300, and the positioning mechanism 400 described in Embodiment 1 or Embodiment 2. The matching block One end of the fixture 200 is provided with the matching block limiting slot 201 , and the assembling jaw 206 is used to clamp the matching block 102 and put it into the matching block limiting slot 201 ; the radiation unit fixture 300 is provided with an internal There is an elastic pin 301, and a matching block limiting slot 201 is provided at a position near the end of the matching block fixture 200; wherein, when the matching block fixture 200 drives the matching block 102 to extend into the radiation unit 100, the The elastic pin 301 in the radiation unit fixture 200 extends into the matching block limiting groove 201 and abuts one end of the matching block 102 .

[0068] like Image 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com