LNG special quick connector

A fast, female joint technology, applied in the direction of pipe/pipe joint/pipe fitting, sealing surface connection, heat preservation, etc., can solve the problems of unable to meet the working conditions of LNG product loading and unloading, the connection method freezes to death, and cannot be disconnected, etc. Achieve the effect of shortening the docking time of ships, improving the utilization rate of the terminal, and improving the connection and separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

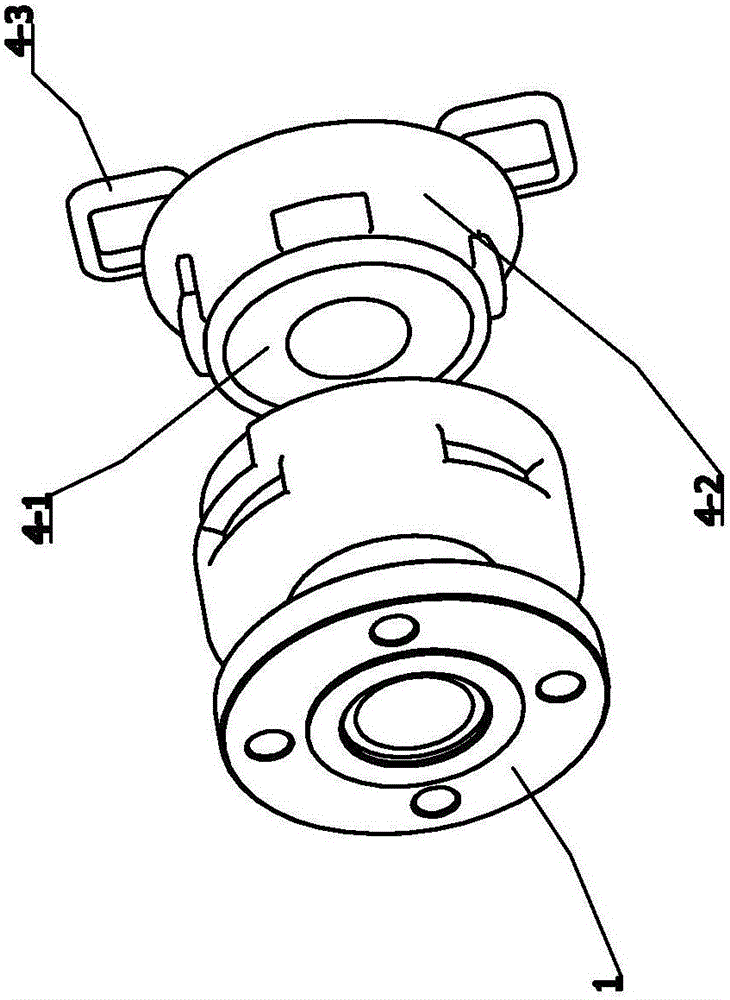

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 The LNG special quick connector shown includes: female connector 1, sealing ring 2 and male connector 3;

[0034] The female joint 1 includes: a female joint connecting clamp 1-1, a female connecting part 1-2 for detachable connection with an external pipeline, and a female connecting clamp 1-1 and a female connecting part 1 for connecting the female joint -2 female head vacuum connecting pipe 1-3;

[0035] The female joint connection chuck 1-1 is provided with an inner hole, and one end of the inner hole communicates with the female vacuum connecting pipe 1-3, and the other end forms an open hole with the outer wall of the female connector connection chuck 1-1, wherein the sealing ring 2 Embedded and positioned at the connection position between the inner hole and the female vacuum connecting pipe 1-3, and axially aligned with the female vacuum connecting pipe 1-3;

[0036] The male joint 3 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com