Anti-freeze oil tank structure

A technology of fuel tanks and oil tanks, which is applied to the substructure, the arrangement combined with the fuel supply of the internal combustion engine, and the power plant. It can solve the problems of long electric heating time of condensed fuel, long start-up driving time, and low electric heating efficiency. It can solve the problem of freezing Phenomenon, reduction of driving restrictions, and effect of reducing failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

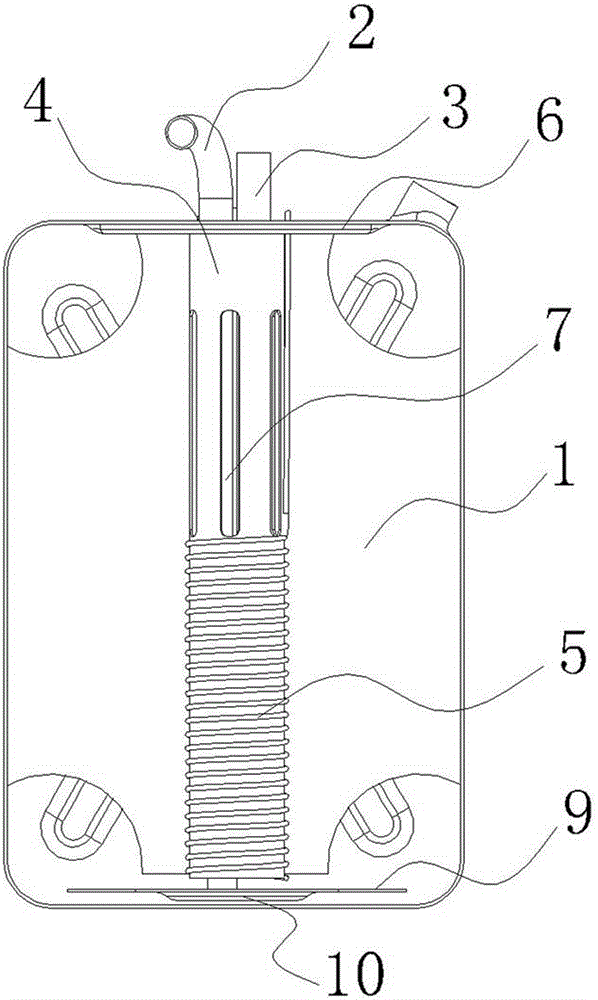

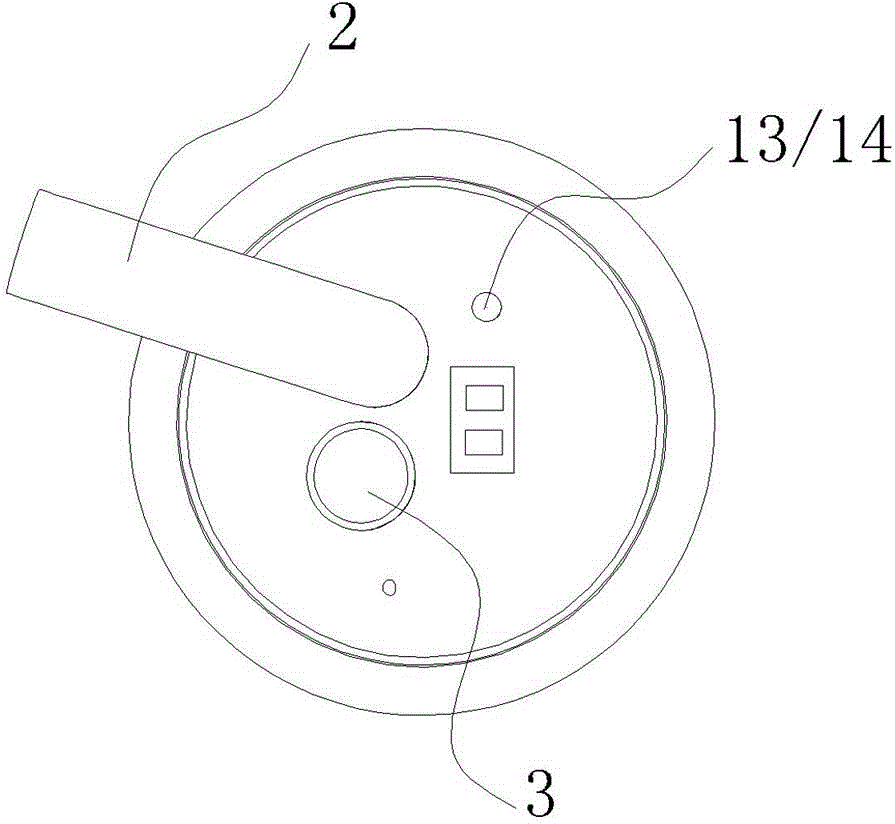

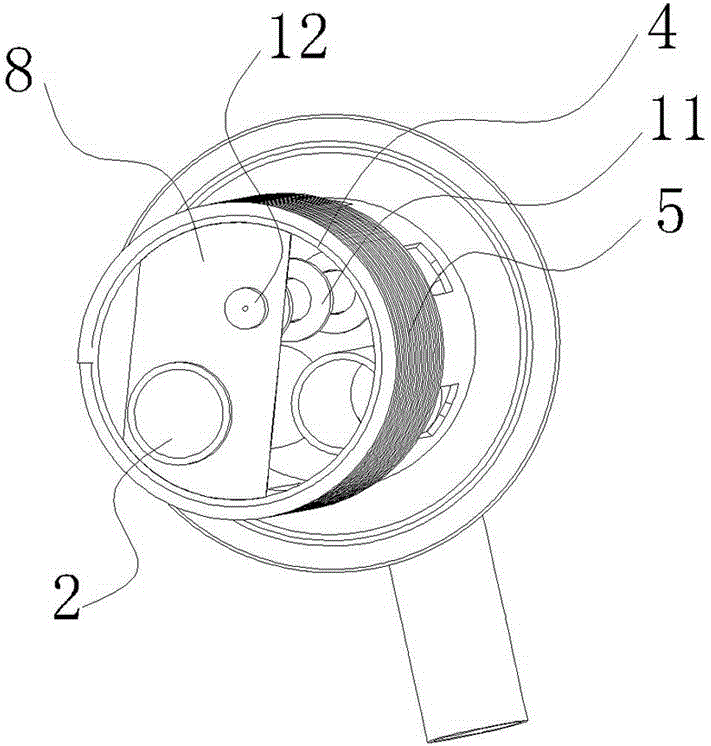

[0024] Such as figure 1 As shown, a kind of antifreeze fuel tank structure of the present invention, comprises the fuel tank 1 of square iron, inserts an oil suction pipe 2 and an oil return pipe 3 at the top of fuel tank 1, the upper end of oil suction pipe 2 and oil return pipe 3 are respectively connected with The oil inlet and the oil outlet of the automobile engine are connected, the lower ends of the oil suction pipe 2 and the oil return pipe 3 extend vertically into the fuel tank 1, and a heat conduction circulation sleeve 4 is vertically installed in the fuel tank 1 corresponding to the oil suction pipe 2 and the oil return pipe 3 , the heat conduction circulation sleeve 4 is made of copper pipe, a fixing plate 6 is welded horizontally on the top of the heat conduction circulation sleeve 4, the heat conduction circulation sleeve 4 is fixed on the top of the fuel tank 1 through the fixation plate 6, the oil suction pipe 2 and the oil return pipe 3 Extend through the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com