High-mirror-surface electrical discharge machining liquid and manufacturing method thereof

A spark machining, high-mirror technology, applied in the field of spark machining fluid, can solve the problems of the mirror effect not meeting the market requirements, the user's skin damage, the odor and corrosiveness, etc., to achieve good mirror effect, long service life, and flash point. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

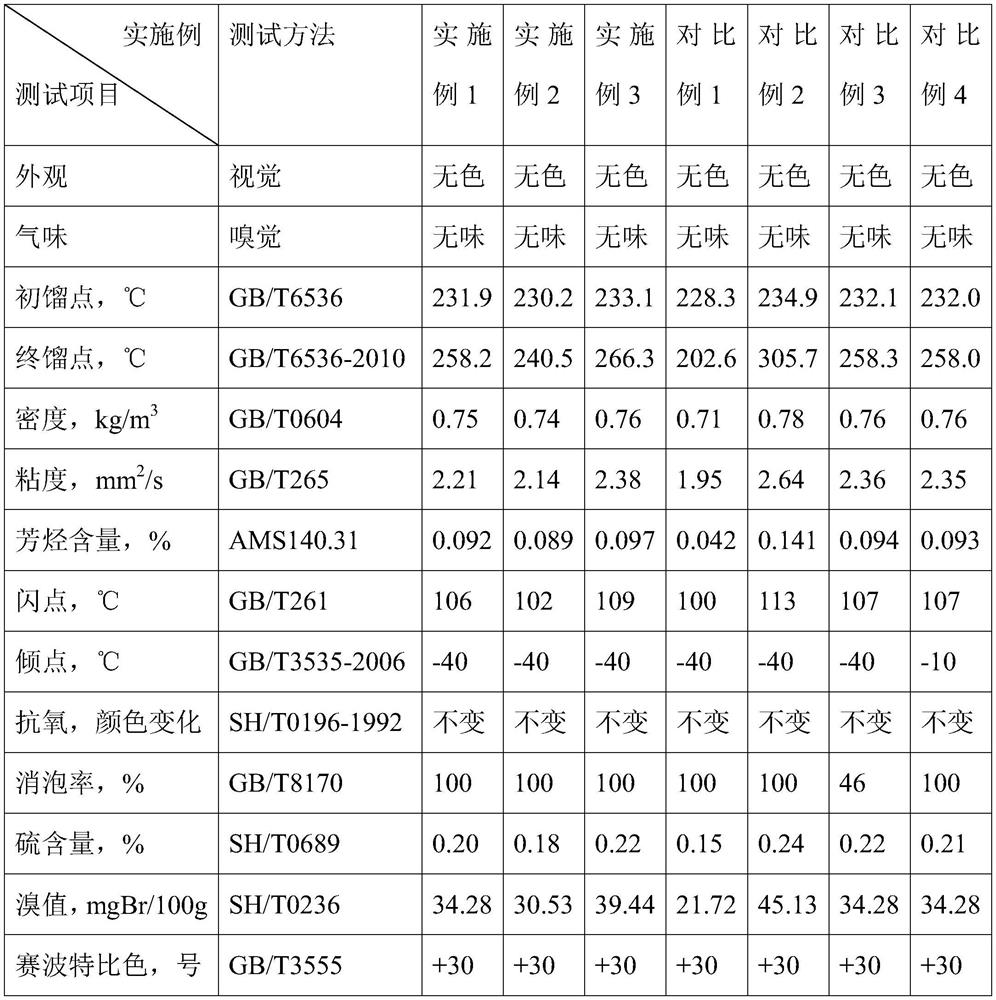

Examples

preparation example Construction

[0025] The present invention also provides a preparation method of the above-mentioned high specular surface spark machining fluid, the preparation method comprising the following steps:

[0026] Step 1, adding isomerized hexadecane, dodecane, antioxidant, antifoaming agent and anticoagulant into the mixer;

[0027] Step 2, stirring with a mixer, the rotating speed is 100 rpm / s, and the stirring time is 30 minutes;

[0028] Step 3: Perform cooling treatment to form a high-mirror surface spark machining fluid.

Embodiment 1

[0030] In this example, the spark machining fluid contains the following components: polymer hydrogenated tetraisobutene fraction of C4-hydrocarbon without 1,3-butadiene 45.2%, dodecane 54.5%, 3-(3,5- Di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate 0.15%, polydimethylsiloxane 0.1%, 6-bromo-2-naphthyl-β-D-galactopyranoside 0.05%.

Embodiment 2

[0032] In this example, the spark machining fluid contains the following components: polymer hydrogenated tetraisobutene fraction of C4-hydrocarbon without 1,3-butadiene 41.2%, dodecane 58.5%, 3-(3,5- Di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate 0.15%, polydimethylsiloxane 0.1%, 6-bromo-2-naphthyl-β-D-galactopyranoside 0.05%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com