Application of plasma modified catalyst in removal of hydrogen sulfide, hydrogen phosphide and arsenic hydride

A technology of plasma and catalyst, which is applied in the field of ion modified catalysts, can solve the problems of simultaneous removal, small adsorption capacity, and low adsorption efficiency, and achieve excellent catalytic activity, high adsorption efficiency, and long-lasting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

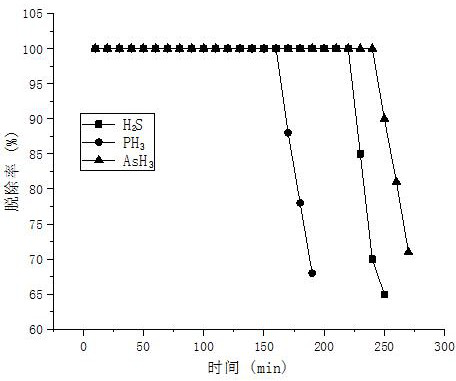

[0025] Embodiment 1 (unmodified embodiment)

[0026] Weigh 1.0g of Cu(NO 3 ) 2 Dissolve in 8.3mL of distilled water, then weigh 0.5g of trimesic acid and add it to the mixture of absolute ethanol and N,N-dimethylformamide (8.3mL of absolute ethanol and 8.3mL of DMF). After mixing the two solutions, place them in an ultrasonic instrument, ultrasonicate for 30 minutes at 25°C (ultrasonic frequency is 35kHz), fully dissolve, transfer the ultrasonically mixed solution to a 100mL polytetrafluoroethylene-lined stainless steel self-pressurized reactor, The reaction kettle was placed in a programmed temperature-controlled oven. The temperature of the oven was raised from room temperature to 85 °C at a rate of 1 °C / min. After reacting at 85 °C for 20 hours, the temperature was naturally lowered to room temperature, and the reaction solution was suction-filtered to obtain crystals Take 50% ethanol aqueous solution and wash with suction for 4 times. After washing, the product is dried ...

Embodiment 2

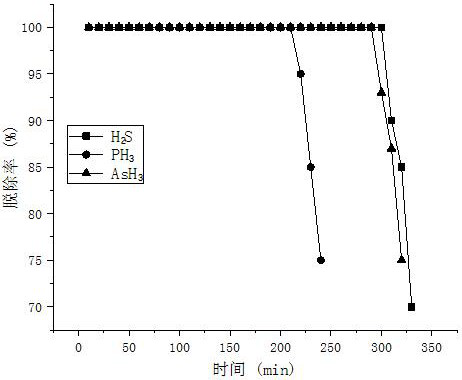

[0028] Weigh 1.0 g of Cu(NO 3 )2 Dissolve in 8.3mL of distilled water, then weigh 0.5g of trimesic acid and add it to the mixture of absolute ethanol and N,N-dimethylformamide (8.3mL of absolute ethanol and 8.3mL of DMF). The above two solutions are mixed and placed in an ultrasonic instrument, ultrasonicated at 25°C for 30 minutes (ultrasonic frequency is 35kHz), fully dissolved, and the ultrasonically mixed solution is transferred to a 100mL polytetrafluoroethylene-lined stainless steel self-pressurized reaction kettle , and put the reaction kettle in a programmed temperature-controlled oven. The temperature of the oven was raised from room temperature to 85 °C at a rate of 1 °C / min, and then reacted at 85 °C for 20 hours and then cooled down to room temperature naturally. The obtained crystals were filtered and washed 4 times in 50% ethanol aqueous solution. After washing, the product was dried in an oven at 60°C for 12 hours, and then vacuumized at 160°C for 5 hours to obt...

Embodiment 3

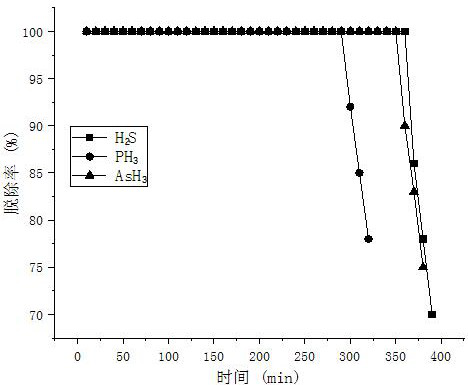

[0031] Weigh 1.0g of Cu(NO 3 ) 2 Dissolve in 8.3mL of distilled water, then weigh 0.5g of trimesic acid and add it to the mixture of absolute ethanol and N,N-dimethylformamide (8.3mL of absolute ethanol and 8.3mL of DMF). The two solutions were mixed and placed in an ultrasonic instrument, ultrasonicated at 30°C for 30 minutes (ultrasonic frequency 35kHz), fully dissolved, and the ultrasonically mixed solution was transferred to a 100mL polytetrafluoroethylene-lined stainless steel self-pressurized reactor. The reaction kettle was placed in a programmed temperature-controlled oven, and the temperature of the oven was raised from room temperature to 85 °C at 2 °C / min, and then reacted at 90 °C for 22 hours, and then cooled down to room temperature naturally, and the reaction solution was suction-filtered to obtain The crystals were filtered and washed three times in 50% ethanol aqueous solution. After washing, the product was dried in an oven at 80°C for 12 hours, and then vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com