Method for simultaneously extracting notoginsenoside, panax notoginseng flavone and panax notoginseng polysaccharide and application thereof

A technology of notoginseng flavonoids and notoginseng polysaccharides, applied in the field of simultaneous extraction of notoginseng saponins, notoginseng flavonoids and notoginseng polysaccharides, can solve the problem of not fully utilizing notoginseng medicinal materials, and achieve good antioxidant activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

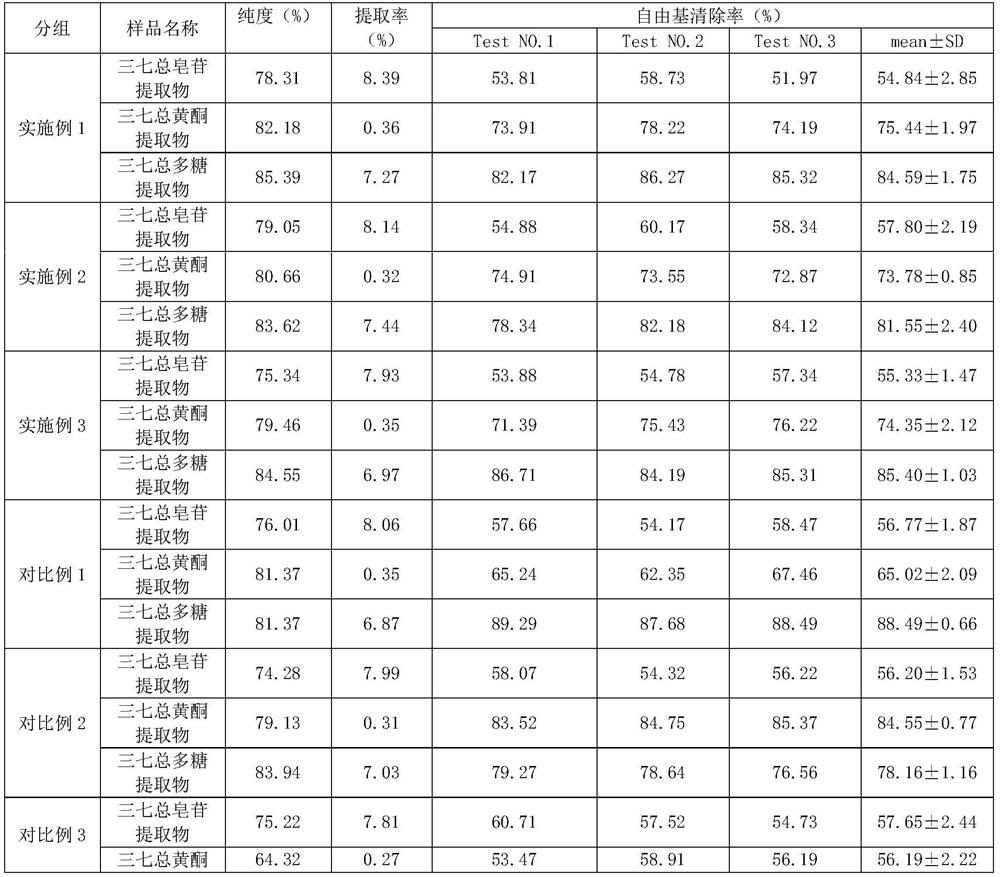

[0034] Take 1 kg of Panax notoginseng medicinal material (the dried root of Panax notoginseng, the moisture content is controlled below 10%) and grind it through 40 meshes to obtain medicinal powder. Add an ethanol solution with a volume fraction of 80% to the medicinal powder (the percentages of all alcohol solutions in this scheme refer to volume percentages), to obtain the first extraction system, and extract by hot dipping at 70° C. for 3 hours. The dosage ratio of the 80% ethanol solution and the notoginseng medicinal material is 6L:1kg. Then filter to obtain extract I and dregs I. The extract I was evaporated and concentrated under reduced pressure, and then freeze-dried to obtain a dry powder extract of Panax notoginseng total saponins. The medicinal residue I is taken, and the culture solution and Bacillus cereus are added to the medicinal residue I to obtain a fermentation system. The addition of nutrient solution is the nutrient solution of every 1kg Panax notogins...

Embodiment 2

[0036] Take 2 kg of Panax notoginseng medicinal material (dried root, water content controlled below 10%), pulverize and pass through 40 meshes to obtain medicinal powder. Add an ethanol solution with a volume fraction of 70% to the medicinal powder to obtain the first extraction system, and extract by hot dipping at 60° C. for 3 hours. The dosage ratio of the 70% ethanol solution and the notoginseng medicinal material is 5L:1kg. Then filter to obtain extract I and dregs I. The extract I was evaporated and concentrated under reduced pressure, and then freeze-dried to obtain a dry powder extract of Panax notoginseng total saponins. Take the dregs I, and add the culture medium and Bacillus cereus (Bacillus cereus) to the dregs I 14579), to obtain a fermentation system. The addition of nutrient solution is the nutrient solution of every 1kg Panax notoginseng medical material corresponding 3L, and the inoculum amount (quality) of bacillus cereus is 8% of the quality of fermenta...

Embodiment 3

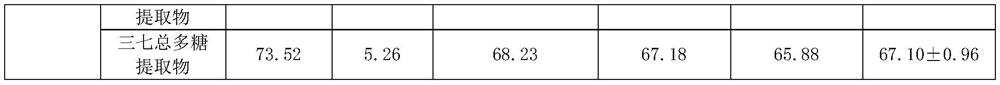

[0038] Take 5 kg of Panax notoginseng medicinal material (dried root, water content controlled below 10%), pulverize and pass through 40 meshes to obtain medicinal powder. Add an ethanol solution with a volume fraction of 90% to the medicinal powder to obtain a first extraction system, and extract by hot soaking at 80° C. for 2 hours. The dosage ratio of the 90% ethanol solution and the notoginseng medicinal material is 8L:1kg. Then filter to obtain extract I and dregs I. The extract I was evaporated and concentrated under reduced pressure, and then freeze-dried to obtain a dry powder extract of Panax notoginseng total saponins. Take the dregs I, and add culture solution and Bacillus cereus (Bacillus cereus) to the dregs I 14579), to obtain a fermentation system. The addition of nutrient solution is the nutrient solution of every 1kg Panax notoginseng medical material corresponding 3L, and the inoculum amount (quality) of Bacillus cereus is 12% of the quality of fermentati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com