Flanged cylindrical battery with spiral wound electrode

A cylindrical battery and spiral winding technology, which is applied in the direction of non-aqueous electrolyte batteries, lithium batteries, secondary batteries, etc., can solve the problems of low working efficiency of the battery pack, inability to ventilate and dissipate the battery pack, and achieve the effect of ensuring the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

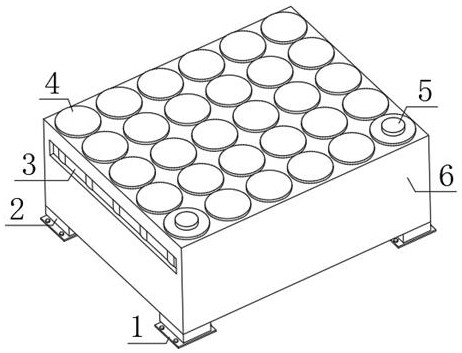

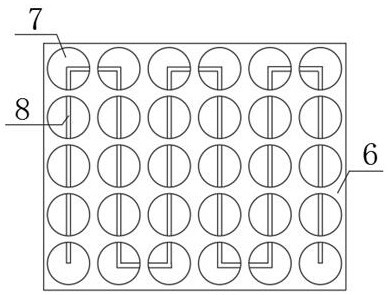

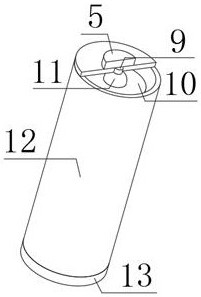

[0030] refer to Figure 1-5 , a flanged cylindrical battery with spirally wound electrodes, including a fixing frame 6, the top outer wall of the fixing frame 6 is provided with placement grooves 7 distributed equidistantly, and the bottom inner wall of the placement groove 7 is provided with installation wire grooves 8, A fixed base 13 is provided on the inner wall of the bottom of the placement groove 7, and a groove is arranged on the outer wall of the top of the fixed base 13, and the groove is set to a structure with a narrow top and a wide bottom, and the bottom inner wall of the groove is provided with through holes 15 distributed in a spiral manner. , a winding unit is provided on the inner wall of the bottom of the groove, and an integrated line is provided on one side of the outer wall of the winding unit, a filling layer 19 is provided inside the integrated line, and an air electrode 16, a first The positive electrode separator 17, the first negative electrode separ...

Embodiment 2

[0039] refer to Image 6 , a flanged cylindrical battery with spirally wound electrodes, including a fixing frame 6, the top outer wall of the fixing frame 6 is provided with placement grooves 7 distributed equidistantly, and the bottom inner wall of the placement groove 7 is provided with installation wire grooves 8, A fixed base 13 is provided on the inner wall of the bottom of the placement groove 7, and a groove is arranged on the outer wall of the top of the fixed base 13, and the groove is set to a structure with a narrow top and a wide bottom, and the bottom inner wall of the groove is provided with through holes 15 distributed in a spiral manner. , a winding unit is provided on the inner wall of the bottom of the groove, and an integrated line is provided on one side of the outer wall of the winding unit, a filling layer 19 is provided inside the integrated line, and an air electrode 16, a first The positive electrode separator 17, the first negative electrode separato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com