Silicon micro-strip detection system

A detection system, silicon micro technology, applied in the direction of measuring devices, radiation measurement, radiation intensity measurement, etc., can solve the problems of increasing the weight and high price of aerospace equipment, and achieve the reduction of the occupied area, the reduction of the area, and the reading of the value Precise and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

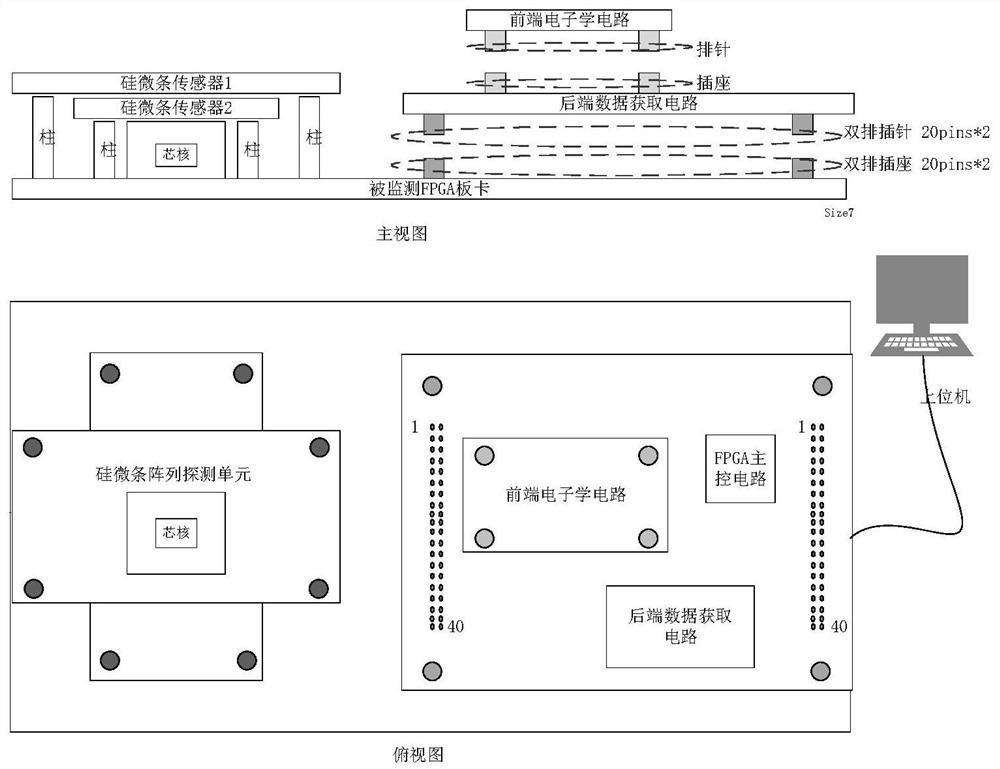

[0039] Such as figure 1 As shown, the present invention proposes a silicon microstrip detection system, including a silicon microstrip array detector, a front-end electronics unit, a back-end data acquisition unit, an FPGA main control unit, and a data processing unit set on a host computer.

[0040] 1. Silicon microstrip array detector

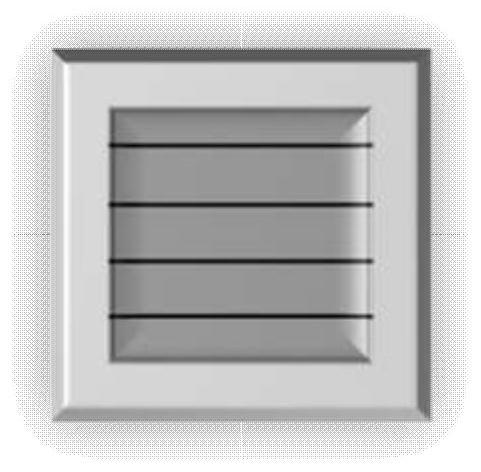

[0041] The silicon microstrip array detector consists of 2 silicon microstrip sensors, and each sensor has 5 detection units (10mm×10mm), such as figure 2 shown.

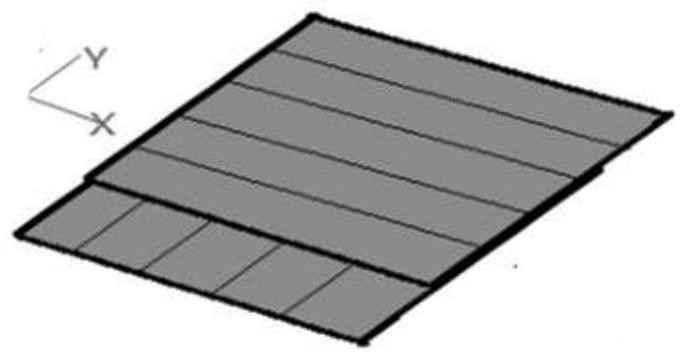

[0042] These two silicon micro-strip sensors form a 5×5 micro-strip array in a vertical and horizontal manner, and each micro-strip has a size of 2mm×2mm, and can output signals independently. The structure of the silicon microstrip array detector is as follows image 3 Shown: from top to bottom are silicon microstrip sensor 1 and silicon mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com