Civil safe anti-backfire biomass cooking and heating furnace

A technology for biomass and stoves, which is applied in household stoves/stoves, lighting and heating equipment, solid heating fuels, etc. It can solve the problems of backfire in silos and lack of anti-backfire functions, so as to prevent coking and slagging, Eliminate coking and slagging, better heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

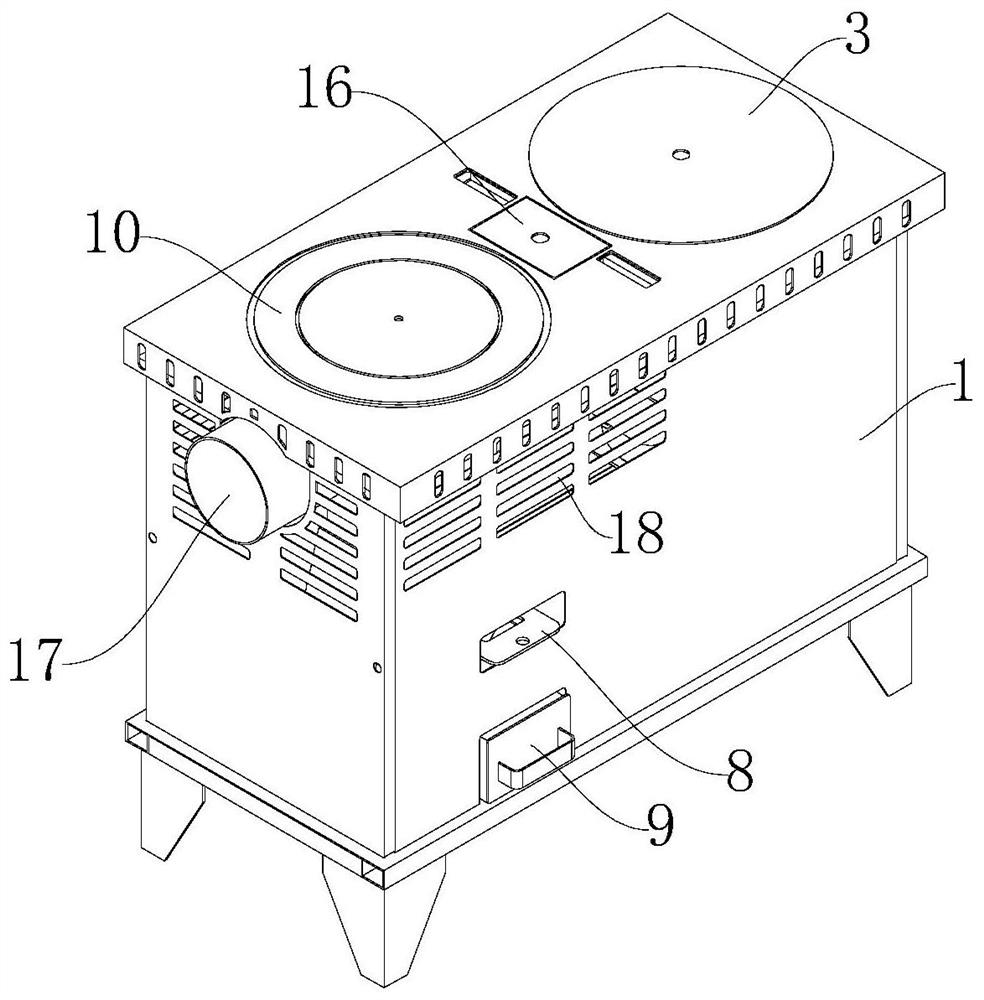

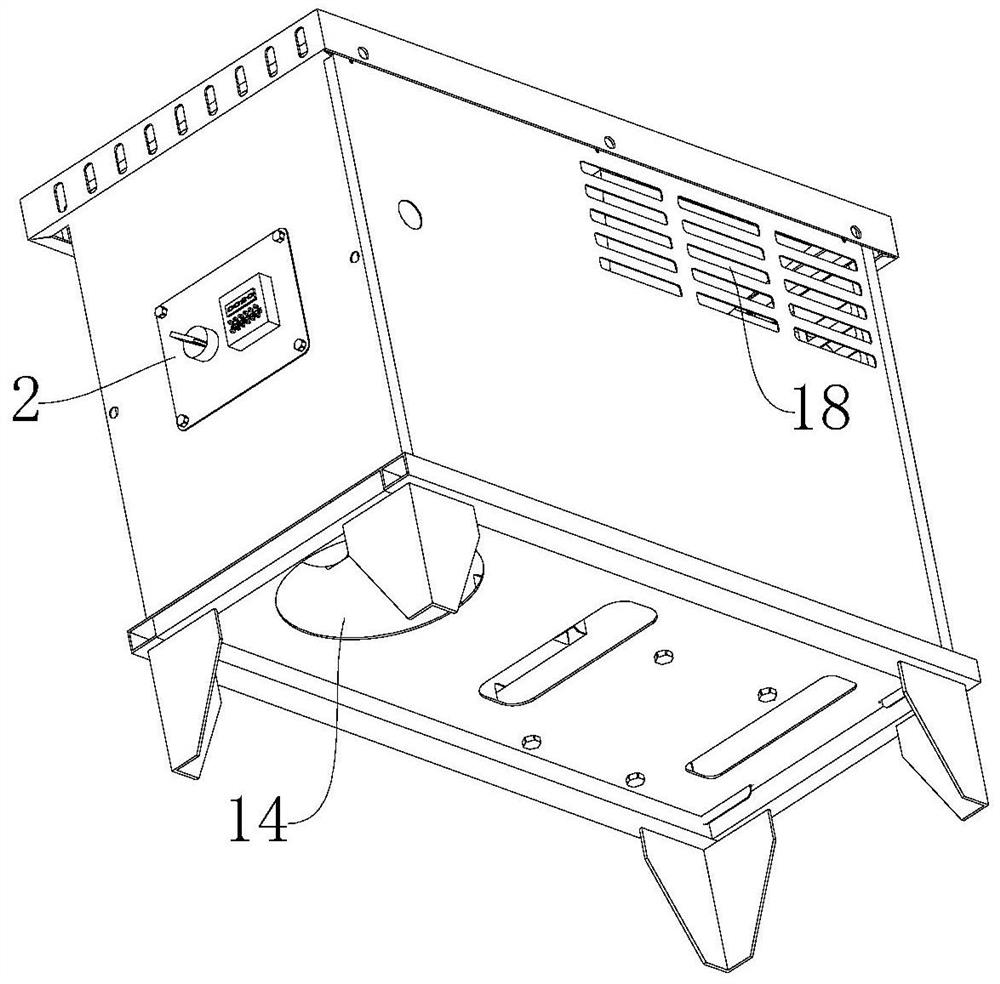

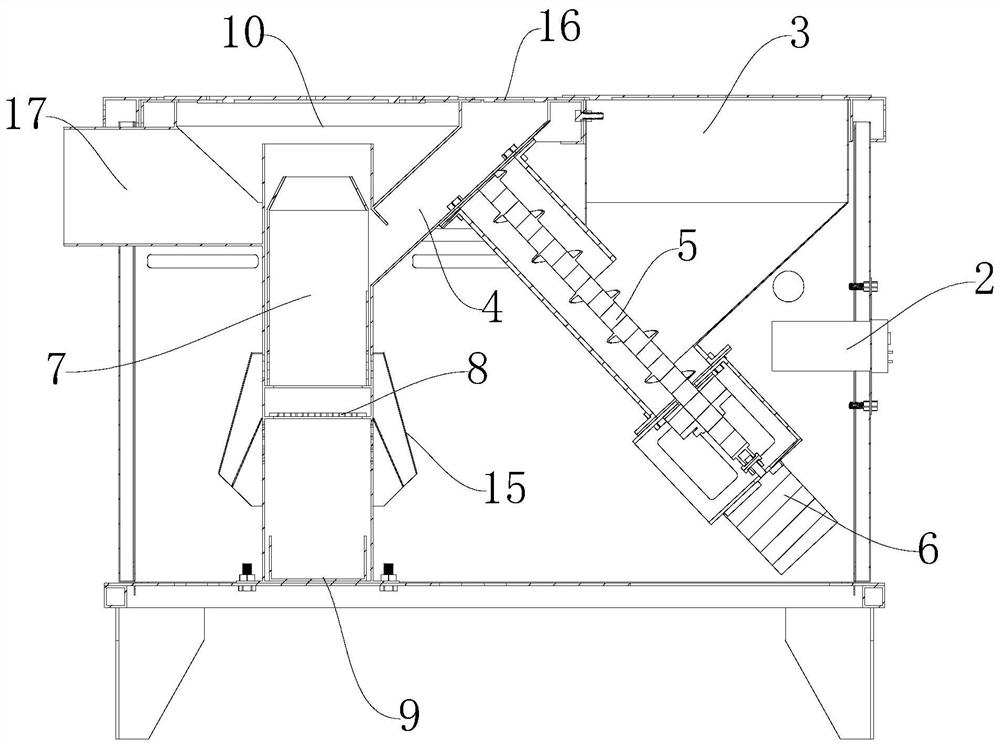

[0030] Such as Figure 1 to Figure 4 As shown, a kind of civil safety anti-backfire biomass cooking and baking stove provided by the embodiment of the present invention includes a furnace body 1 and a feeding anti-backfire system, a gasification combustion system, and a controller 2 arranged in the furnace body 1 and anti-radiation structure;

[0031] The feeding anti-backfire system includes a hopper 3, an anti-backfire blanking port 4, a feeding channel for connecting the hopper 3 and the anti-backfire blanking port 4, and is installed on the feeding The feed auger 5 in the channel and the motor 6 for driving the feed auger 4;

[0032] The controller 2 is installed on the furnace body 1 and is electrically connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com