Spinning solution and preparation method thereof and antibacterial copper ammonia fabric and preparation method thereof

A spinning solution and cupramine technology, which can be used in spinning solution preparation, rayon manufacturing, textiles and papermaking, etc., can solve problems such as large performance decline, achieve excellent bacteriostatic properties, improve fabric strength, and improve performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The present invention also relates to a preparation method of a spinning solution, comprising the following steps: 1. Add 1,3-propanediol into a first stirring container, then add graphene powder, and stir evenly (rotating speed is between 150rpm-380rpm ), to obtain a uniform additive solution, and then stand for degassing for 2-6h under a temperature environment of 50°C-55°C, and the temperature during stirring in step 1 is 50°C-55°C, and graphene has an optimal dispersion effect. 2. Add the cupro ammonia spinning solution into the second stirring container, then add the additive solution prepared in step 1, and stir evenly (the rotating speed is between 75rpm-150rpm) to obtain the spinning solution, and the spinning solution after stirring evenly The silk liquid can be spun.

[0020] The present invention also relates to a method for preparing an antibacterial cupro fabric, the preparation method of the antibacterial cupro fabric includes a spinning preparation proce...

Embodiment 1

[0026] Graphene fluffy powder (accounting for 0.015% of the mass of spinning solution), 1,3-propanediol (accounting for 6% of the mass of spinning solution), copper ammonia spinning solution (accounting for 93.985% of the mass of spinning solution);

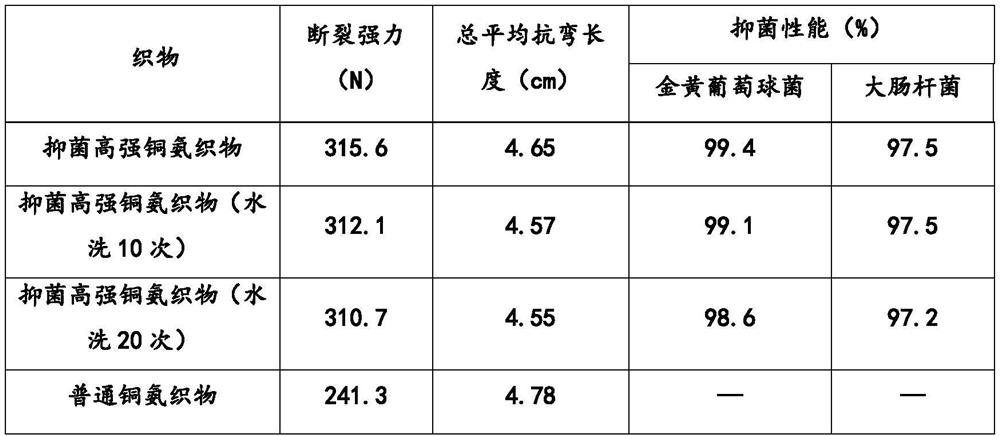

[0027] The antibacterial high-strength cupro ammonia fabric of this example (86.5g / m 2 ), antibacterial, breaking strength and softness (total average flexural length, the lower the softer) the effect is as follows

[0028] Table 1 Example 1 antibacterial high-strength copper ammonia fabric performance test

[0029]

[0030] The antibacterial high-strength cupro ammonia fabric prepared in this example has higher breaking strength, and its softness is better than that of ordinary cupro ammonia fabric. Not obvious either. This is because the antibacterial graphene is dispersed in the spinning solution to prepare cupro ammonia fibers, and its fixation fastness is excellent. 1,3-propanediol is another main component in the spin...

Embodiment 2

[0032] Graphene fluffy powder (accounting for 0.025% of the mass of the spinning solution), 1,3-propanediol (accounting for 12% of the mass of the spinning solution), cuproammonia spinning solution (accounting for 87.975% of the mass of the spinning solution);

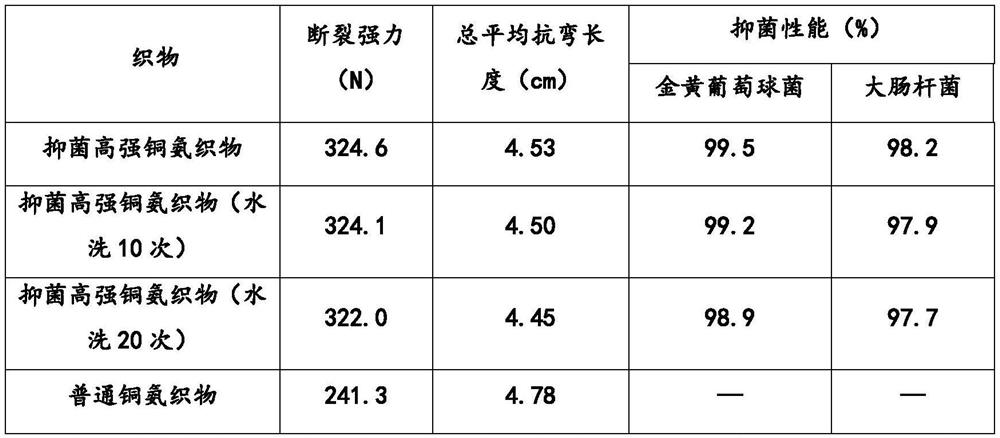

[0033] The antibacterial high-strength cupro ammonia fabric of this example (87.4g / m 2 ), antibacterial, breaking strength and softness (total average flexural length, the lower the softer) the effect is as follows

[0034] Table 2 Example 2 antibacterial high-strength copper ammonia fabric performance test

[0035]

[0036] The antibacterial high-strength cupro ammonia fabric prepared in this example has higher breaking strength, and its softness is better than that of ordinary cupro ammonia fabric. Not obvious either. Graphene fluffy powder accounts for spinning solution quality 0.025% consumption is higher than embodiment 1, antibacterial effect is slightly better than embodiment 1, but not obvious, 1,3-propane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com