Coal slime curing and upgrading agent

A curing agent and coal slime technology, applied in solid fuel, fuel additive, petroleum industry, etc., can solve problems such as increasing safety risks, restricting properties, increasing nitrogen oxide emissions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

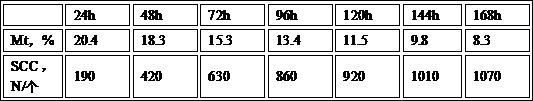

[0019] Embodiment 1: The present invention provides a technical solution: anthracite coal slime (containing 21% water)

[0020] A coal slime solidification and upgrading agent, in terms of weight ratio, the mixed coal slime is composed of 4% coal slime solidification and upgrading agent and 96% anthracite coal slime, wherein the coal slime solidification and upgrading agent is composed of anhydrous Magnesium chloride is 42%, heavy magnesium oxide is 20.5%, polyacrylate is 11%, magnesium sulfate is 33%, and quicklime is 8.5%.

[0021]

Embodiment 2

[0022] Embodiment 2: The present invention provides a technical solution: anthracite coal slime (containing 21.4% water)

[0023] A coal slime solidification and upgrading agent, in terms of weight ratio, the mixed coal slime is composed of 3% coal slime solidification and upgrading agent and 97% anthracite coal slime, wherein the coal slime solidification and upgrading agent is composed of anhydrous Magnesium chloride is 42%, heavy magnesium oxide is 20.5%, polyacrylate is 11%, magnesium sulfate is 33%, and quicklime is 8.5%.

[0024]

Embodiment 3

[0025] Embodiment 3: The present invention provides a technical solution: bituminous coal slime (containing 35.3% water)

[0026]A coal slime solidification and upgrading agent, in terms of weight ratio, the mixed coal slime is composed of 6% coal slime solidification and upgrading agent and 94% bituminous coal slime, wherein the coal slime solidification and upgrading agent is composed of anhydrous Magnesium chloride is 42%, heavy magnesium oxide is 20.5%, polyacrylate is 11%, magnesium sulfate is 33%, and quicklime is 8.5%.

[0027]

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com