Water-based ink conveying cylinder with stirring function

A water-based ink, functional technology, applied in the direction of transportation and packaging, mixer accessories, containers, etc., can solve the problems of ink loss, poor use effect, ink hanging on the wall, etc., to avoid ink loss, ensure quality, and avoid layering and hardening Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

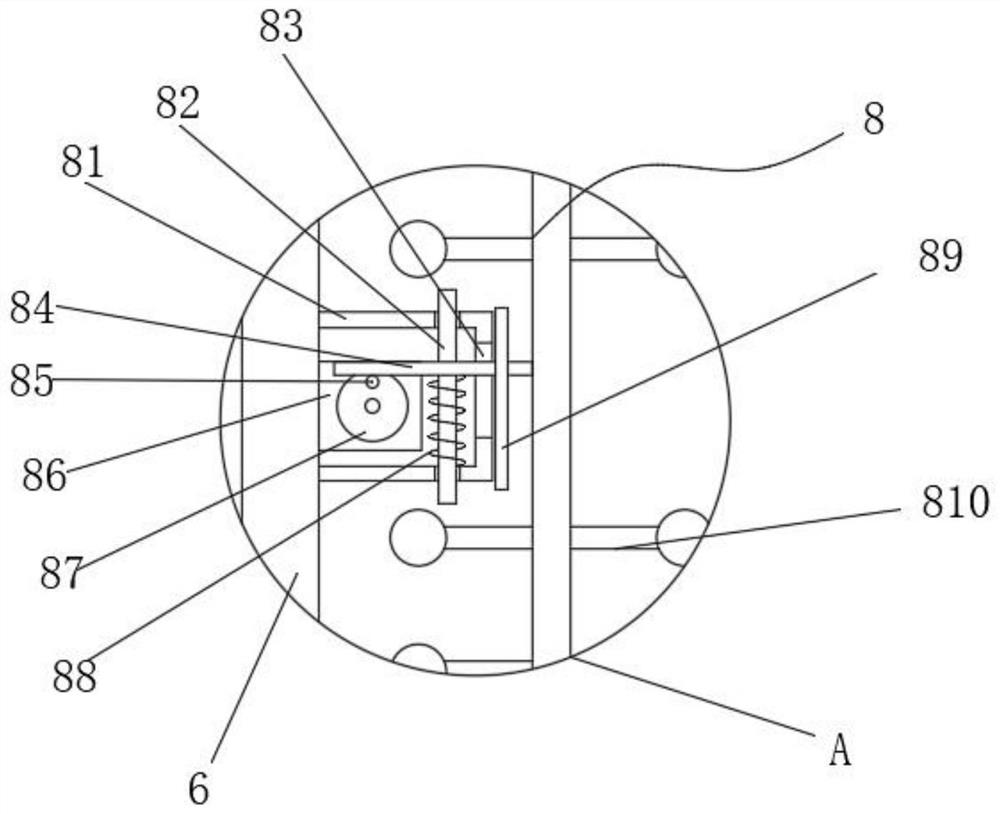

[0027] As an embodiment of the present invention, the oscillating structure 8 includes a sealing frame 81, a limit rod 82, a movable hole 83, a vibrating bar 84, a swing rod 85, an oscillating motor 86, a rotating disk 87, a telescopic spring 88, and a sealing plate 89 and vibrating frame 810, the oscillating motor 86 is mounted on one side of the inner wall of the sealing frame 81, the rotating shaft of the oscillating motor 86 is equipped with a rotating disc 87, and the eccentric position of the end face of the rotating disc 87 is equipped with a swing Rod 85, a movable hole 83 is provided in one side frame wall of the sealing frame 81, a vibrating bar 84 is arranged inside the movable hole 83, and a sealing plate 89 is fixed on one end of the vibrating bar 84, and the sealing plate 89 is welded with a vibration frame 810, and the upper and lower sides of the middle part of the vibration bar 84 are vertically welded with limit rods 82, and the two limit rods 82 are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com