Large-opening composite shell, forming method and forming tool

A technology of composite materials and molding methods, applied in jet propulsion devices, rocket engine devices, machines/engines, etc., to achieve the effects of reducing the difficulty of molding process, simplifying the structure, and improving the molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

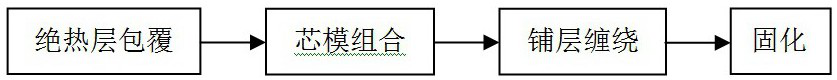

Method used

Image

Examples

Embodiment Construction

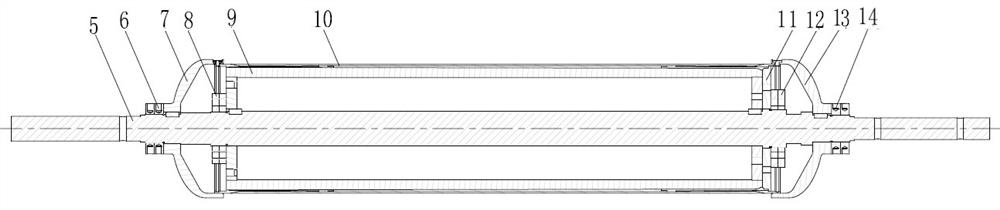

[0029] The present invention will be further described below in conjunction with the accompanying drawings and with the specific embodiment of the removal operation of a certain type of solid rocket motor nozzle blockage.

[0030] 1. Large opening composite material shell structure

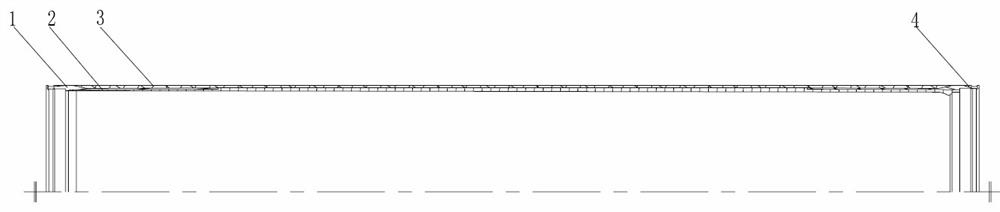

[0031] as attached figure 1 As shown, it is a schematic diagram of a light-weight, high-pressure and powerful open composite material shell, with front joints 1 and rear joints 4 at both ends, the inner layer is a heat insulating layer 2, and the outer layer is a fiber-reinforced plastic shell 3. The outer layer is a carbon fiber / epoxy composite layer.

[0032] According to the structural size and performance requirements of the solid rocket motor combustion chamber shell, the metal joints, heat insulation layer, composite material layer and other parameters of the large-opening composite shell are designed, and the structural scheme of the large-opening composite shell is determined. The shape ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| winding tension | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com