A clamping device and clamping method for self-centering adjustable machine

A clamping device and self-centering technology, applied in the field of mechanical clamping, can solve the problems of unguaranteed alignment accuracy, long processing preparation time, and difficult clamping, so as to improve product processing quality, improve tooling utilization, The effect of improving clamping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose, content and advantages of the present invention clearer, the specific embodiments of the present invention will be described in further detail below.

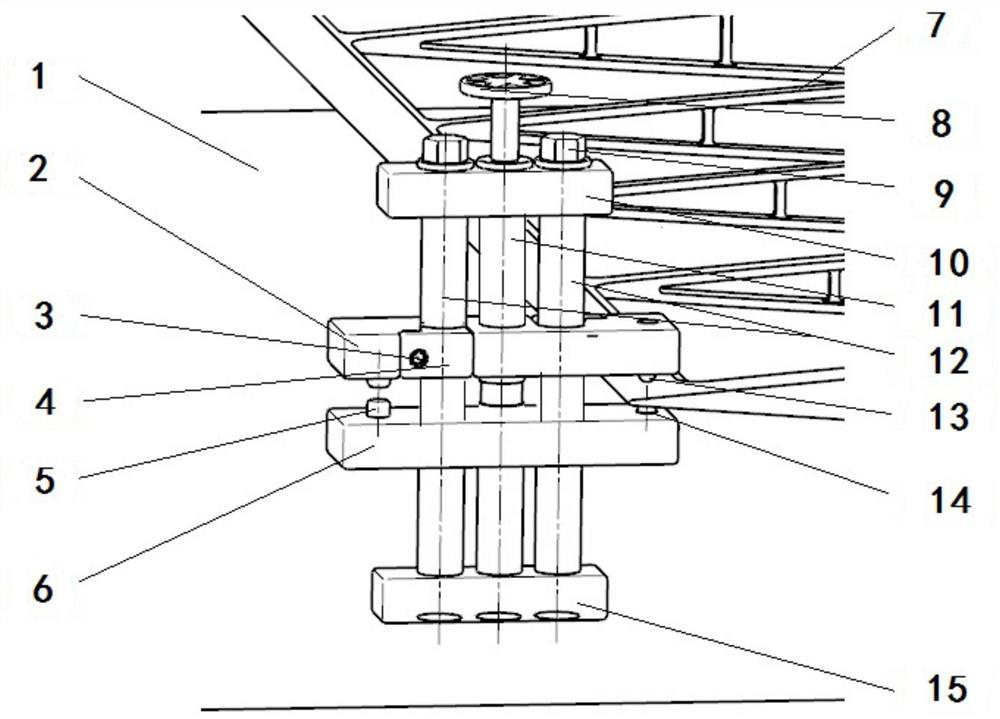

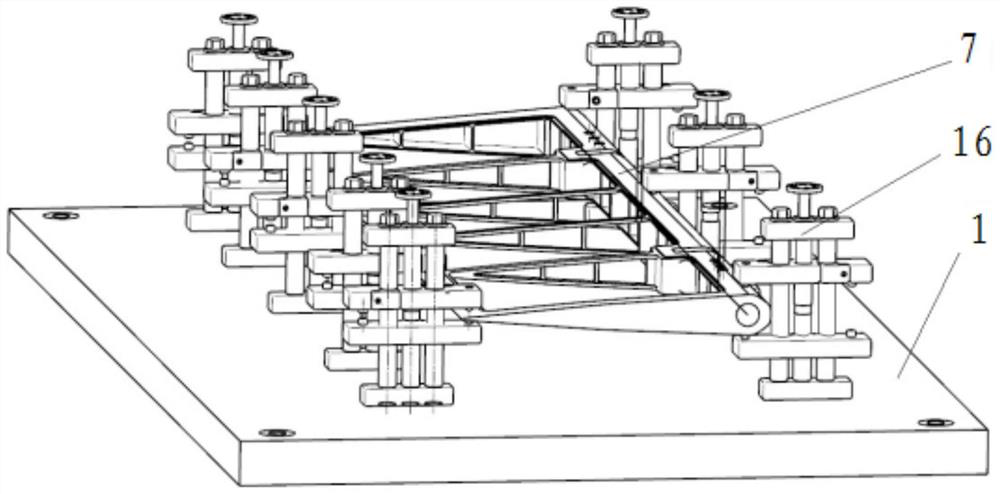

[0018] A self-centering and adjustable machine installation clamping device proposed by the present invention includes a base plate 1 and multiple sets of clamping toolings arranged on the base plate. 3. Limit block 4, pressure plate accuracy calibration pin 5, lower pressure plate 6, hand wheel 8, hexagon screw 9, upper positioning block 10, forward and reverse screw 11, polished rod 12, upper pressure plate universal positioning pin 13, lower pressure plate 10,000 To the positioning pin 14, the lower positioning block 15;

[0019] The forward and reverse screw 11 and the polished rod 12 are arranged side by side and pass through the upper positioning block 10, the upper pressing plate 2, the lower pressing plate 6, and the lower positioning block 15 in order from top to bottom.

[0020] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com