Multifunctional cutting equipment special for nodular cast iron

A technology of ductile iron and cutting equipment, which is applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of hidden safety hazards for operators, low operating efficiency, and loud noise of blades, and achieve improved operating environment, low noise, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

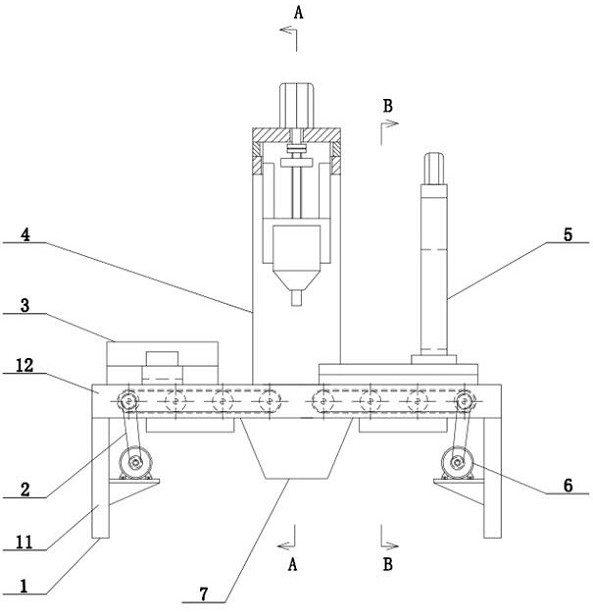

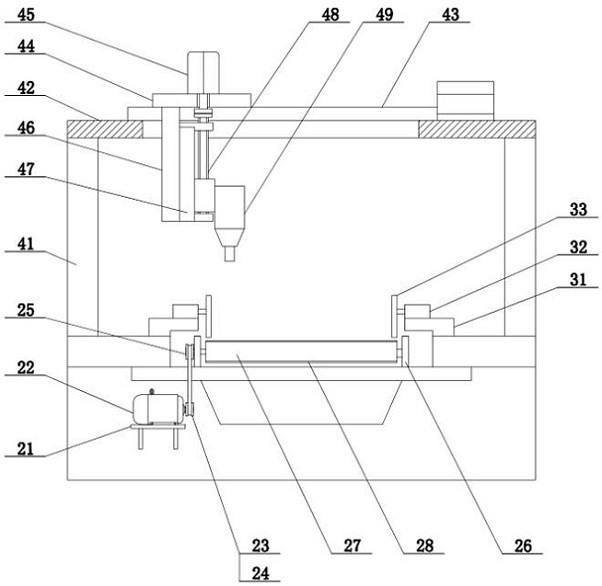

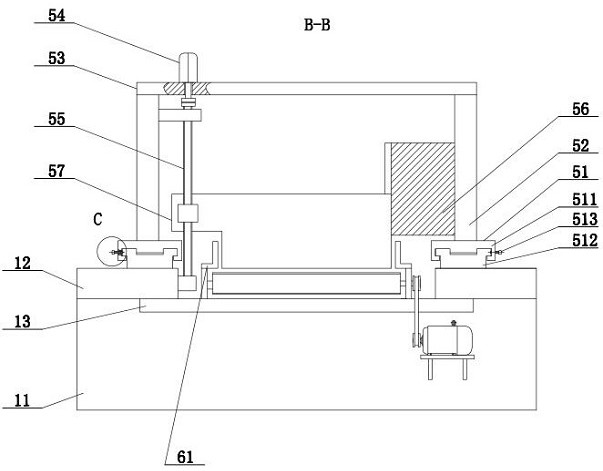

[0022] see Figure 1-Figure 4 As shown, the technical solution adopted in this specific embodiment is: it includes a bracket 1, a feeding mechanism 2, a feeding guide mechanism 3, a laser cutting mechanism 4, a positioning mechanism 5, a discharging mechanism 6, and a chip storage tank 7; The upper part is provided with a feeding mechanism 2, a laser cutting mechanism 4, and a discharging mechanism 6 in turn from left to right; furthermore, the upper part of the feeding mechanism 2 is provided with a feeding guide mechanism 2, and the upper part of the discharging mechanism 6 is provided with a positioning mechanism 5; The groove 7 is arranged directly below the laser cutting mechanism 4; the laser cutting mechanism 4 includes a second support plate 41, a second horizontal plate 42, an electric guide rail 43, a motor mounting plate 44, a second motor 45, and an adapter plate 46 , guide rail 47, first threaded mandrel assembly 48, laser assembly 49; The second support plate 41 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com