Micro-bubble generation device, and micro-bubble generation control method and device

A micro-bubble generation, gas-liquid technology, applied in the direction of mixing methods, chemical instruments and methods, transportation and packaging, etc., can solve the problems of fluid dissipation energy increase, micro-bubble size dispersion, micro-bubble coalescence, etc. Increase and decrease fluid energy dissipation and avoid coalescence effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

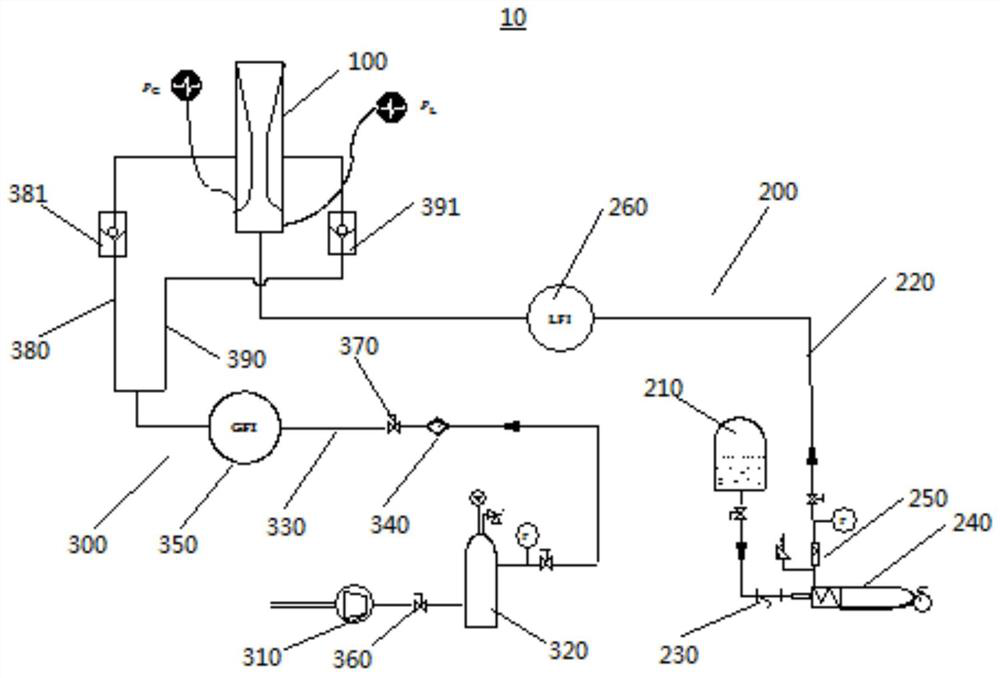

[0044] This embodiment provides a microbubble generation control device, the structure of which is shown in figure 1 , the specific parameters are as follows:

[0045] The liquid inlet section 110 has a diameter of 14 mm and a length of 60 mm. A liquid pressure measuring hole 112 with a diameter of 5 mm is installed in the middle of the liquid inlet section 110 near the liquid inlet 101 and is connected to a liquid pressure measuring sensor 113 .

[0046] The arc radius R of the first arc 121 of the contraction section 120 1 is 7mm, the arc radius R of the second arc 122 2 is 10 mm, and the two arcs are tangent to the liquid inlet section 110 and the gas distribution porous pipe 131 respectively.

[0047] The upper and lower sides of the air intake section 130 are respectively equipped with an air intake hole 133 with a diameter of 4 mm, and the air intake section 130 close to the contraction section 120 is equipped with a gas pressure measuring hole 135 with a diameter of 3...

Embodiment 2

[0052] This embodiment provides a microbubble generation control device, which differs from Embodiment 1 only in that: the diameter of the liquid inlet section 110 is 30 mm, the length is 140 mm, the diameter of the liquid pressure measuring hole 112 is 8 mm; the first circle of the contraction section 120 Arc radius R of arc 121 1 is 15mm, the arc radius R of the second arc 122 2 21mm; the diameter of air inlet 133 on the upper and lower sides of air intake section 130 is 10mm, and the diameter of gas pressure measuring hole 135 is 8mm; the inner diameter of gas distribution porous pipe 131 is 20mm, the aspect ratio is 5, and the wall thickness is 8mm. The gas distribution porous tube 131 has a pore diameter of 300 μm; the angle between the contour line of the expansion section 140 and the axis is 5°, and the length of the expansion section 140 is 100 mm; the gas-liquid expansion section 150 has a diameter of 37.5 mm and a length of 100 mm; except for the gas distribution por...

Embodiment 3

[0055] This embodiment provides a microbubble generation control device, which differs from Embodiment 1 only in that: the diameter of the liquid inlet section 110 is 12 mm, the length of the liquid inlet section 110 is 80 mm, the diameter of the liquid pressure measuring hole 112 is 5 mm; the contraction section 120 The arc radius R of the first arc 121 1 is 6mm, the arc radius R of the second arc 122 2 The diameter of the air inlet 133 on both sides of the upper and lower sides of the air inlet section 130 is 4mm, and the diameter of the gas pressure measuring hole 135 is 2mm; the inner diameter of the gas distribution porous tube 131 is 4mm, the aspect ratio is 1, and the wall thickness is 2mm. The gas distribution porous tube 131 has a pore diameter of 3 μm; the angle between the outline of the expansion section 140 and the axis is 3°, and the length of the expansion section 140 is 40 mm; the gas-liquid expansion section 150 has a diameter of 8.2 mm and a length of 50 mm; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com