A kind of electrodialysis purification system and purification method of solid phase system

A purification method and electrodialysis technology, applied in electrodialysis, chemical instruments and methods, membranes, etc., can solve problems that have not yet been applied in industrial applications, and achieve the effects of enhancing conductivity, reducing corrosion rate, and preventing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

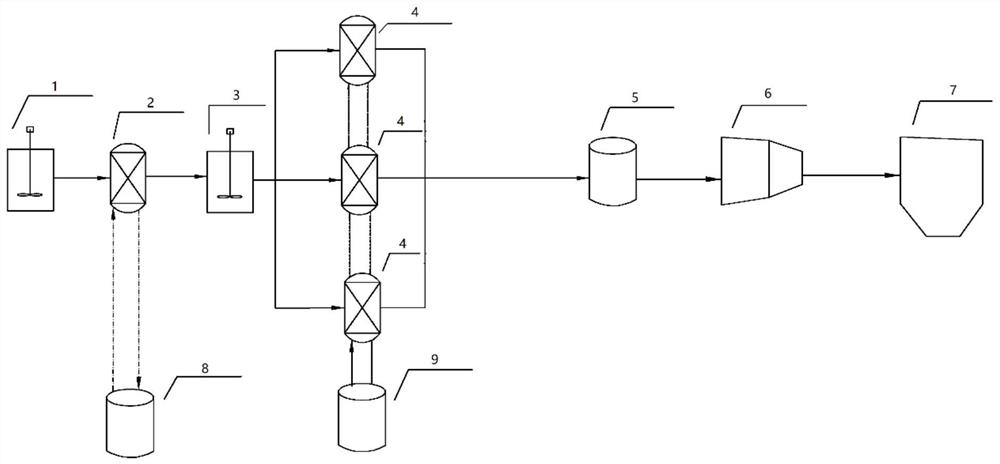

[0085] see figure 1 , an electrodialysis purification system includes: a material pre-dispersion device 1, a primary electrodialysis device 2, a buffer storage device 3, three secondary electrodialysis devices 4, a storage device 5, a centrifugal device 6, a drying device 7, a first Electrolyte circulation device 8 and second electrode circulation device 9, the slurry is transported and connected through pipelines between each device; the first-level electrodialysis device 2 is externally connected with a first electrode circulation device 8; The electrodialysis device 4 is externally connected with a second electrode circulation device 9 . The two-stage electrodialysis devices may be plural, and the plural two-stage electrodialysis devices are externally connected to the same second electrode circulation device.

Embodiment 2

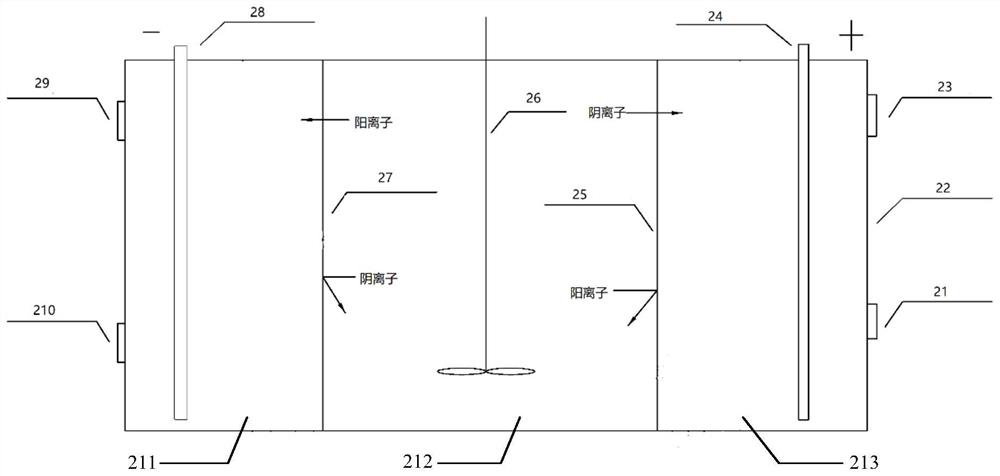

[0087] see figure 2 , the primary electrodialysis device includes a first casing 22, and the first casing 22 is provided with a first anode chamber 213, a first anode membrane 25, a first material chamber 212, a first cathode membrane 27 and a first The cathode chamber 211, the first anode chamber 213, the first material chamber 212 and the first cathode chamber 211 are formed by the first anode film 25 and the first cathode film 27 spaced apart. The surface of the cathode membrane 27 adjacent to the first material chamber 212 is provided with a dialysis membrane layer; the first anode membrane 25 is a monovalent and / or divalent anion exchange membrane; the first cathode membrane 27 is a Valence and / or divalent cation exchange membrane; the first anolyte circulation feed port 21 and the first anolyte circulation outlet 23 are connected with the first anolyte circulation device to realize the circulation of the first anolyte, the The first catholyte circulation feed port 210 ...

Embodiment 3

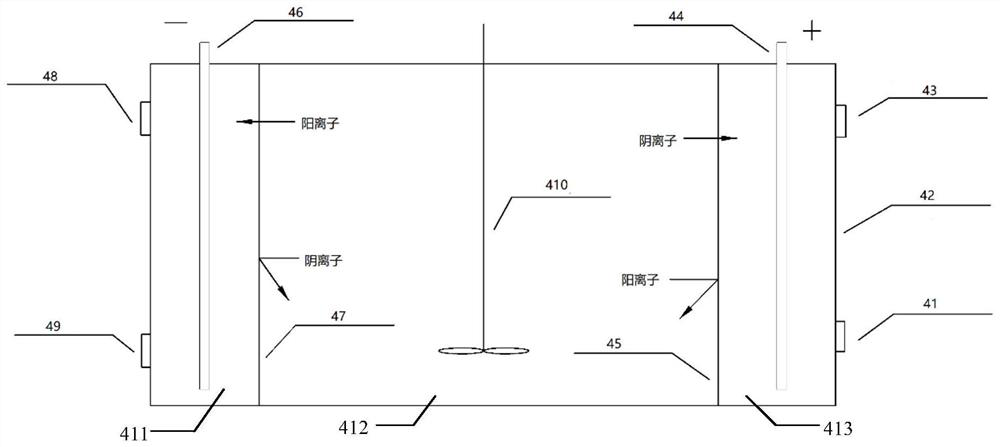

[0089]see image 3 , the secondary electrodialysis device includes a second casing 42, and the second casing 42 is provided with a second anode chamber 413, a second anode membrane 45, a second material chamber 412, a second cathode membrane 47 and a second The cathode chamber 411, the second anode chamber 413, the second material chamber 412 and the second cathode chamber 411 are formed by the second anode film 45 and the second cathode film 47 spaced apart. The surface of the cathode membrane 47 adjacent to the second material chamber 412 is provided with a dialysis membrane layer; the second anode membrane 45 is a monovalent anion exchange membrane; the second cathode membrane 47 is a monovalent cation exchange membrane. The second anolyte circulation feed port 41 and the second anolyte circulation discharge port 43 are connected with the second anolyte circulation device to realize the circulation of the second anolyte. The second catholyte circulation feed port 49, The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com