Environment-friendly sludge discharge device for sewage treatment

A technology for sewage treatment and sludge discharge devices, which is applied in the fields of filtration and separation, fixed filter element filters, chemical instruments and methods, etc., can solve the problems of time-consuming, inability to use sewage treatment devices, etc., and achieve good filtration effect and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

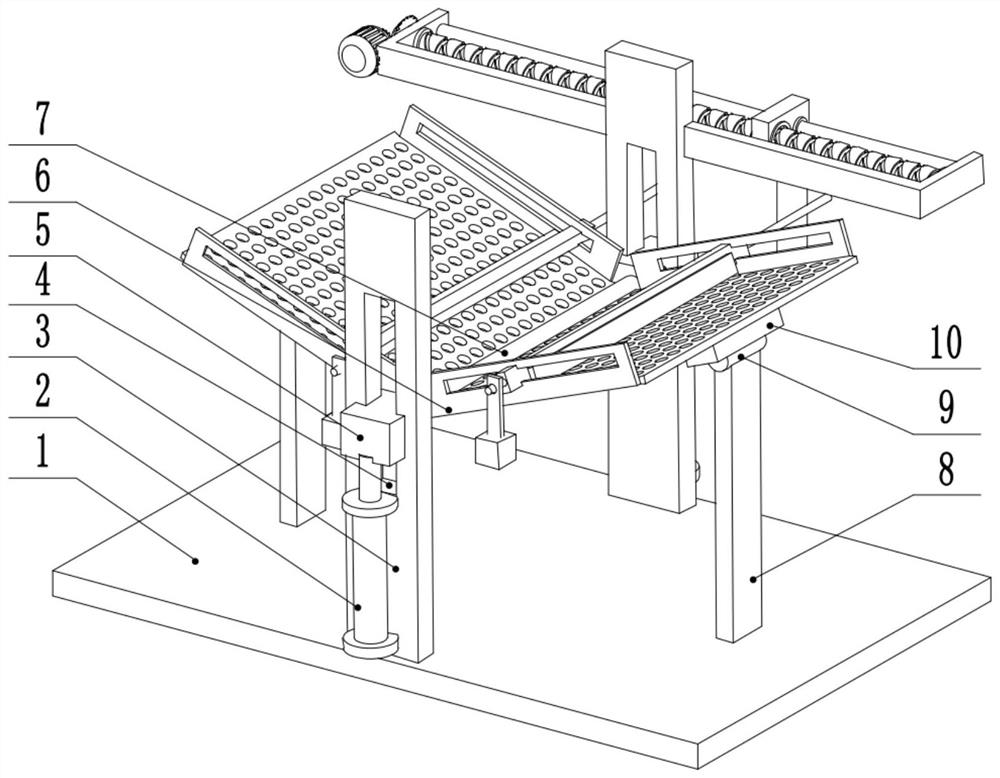

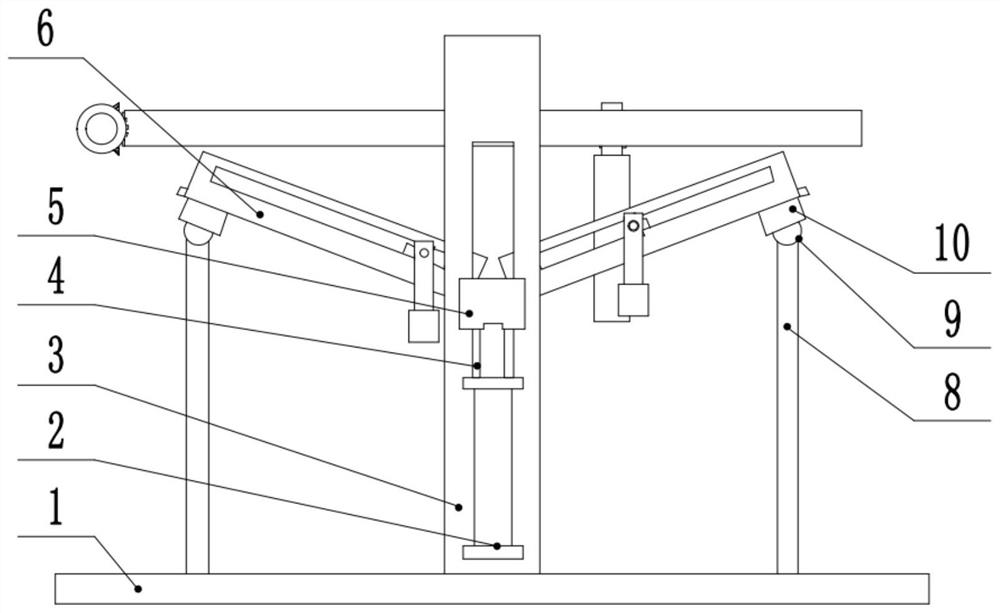

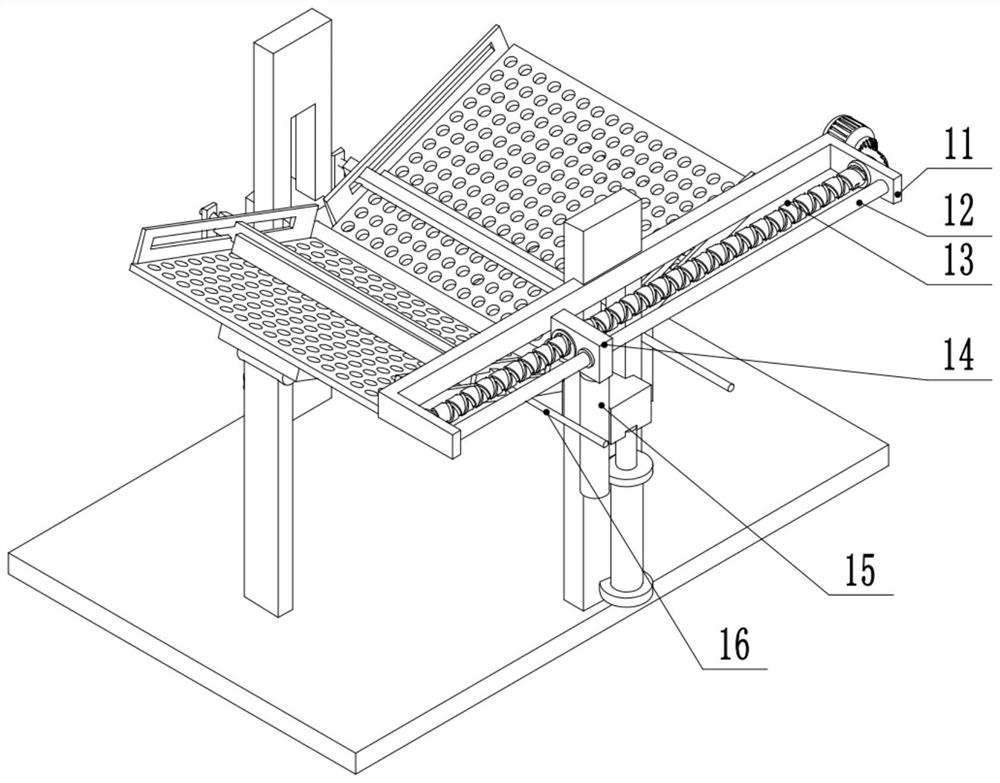

[0025] see Figure 1-5 , an environment-friendly sludge discharge device for sewage treatment, comprising a base plate 1, support plates 3 are provided on the front and rear sides of the upper surface of the base plate 1, a first chute 4 is provided on the top of the support plate 3, and the middle part of the first chute 4 The first slide block 5 is slidably connected, and a rotating shaft 7 is arranged between the two first sliding blocks 5. The left and right sides of the rotating shaft 7 are connected to one end of the filter plate 6 near the center of the device in rotation, and the upper surface of the bottom plate 1 is left and right Both sides are provided with supporting column 8, and the upper end of supporting column 8 is provided with rotating base 9, and the top of rotating base 9 is provided with supporting block 10, and the upper surface of supporting block 10 is slidably connected with the lower surface of filter plate 6. The middle part of the filter plate 6 i...

Embodiment 2

[0029] see Figure 5 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the front end of the second slider 23 is provided with a second fixed rod 26, and the middle part of the second fixed rod 26 is connected to the upper end of the fixed plate 24, The lower end of the fixed plate 24 is provided with a counterweight 25 . The second slider 23 can keep sliding downward under the action of its own gravity, but when mud is attached to the device, it will hinder the second slider 23 to a certain extent, affecting the direction of the second slider 23. slide down, so at this moment, a counterweight 25 can be set on the front side of the second slider 23, and the force value of the second slider 23 moving downward can be improved by setting the counterweight 25, so that the second slider 23 can Fight the drag from silt for a smoother downward movement.

[0030] In the implementation process of the present invention, firstly, when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com