Sand-water separation system for efficiently separating sand in sewage and using method

A technology of sand-water separation and water separator, applied in the direction of separation method, filtration separation, sedimentation separation, etc., can solve the problems of sand running, low interception efficiency, low sand removal efficiency, etc., to reduce energy consumption, improve effect, improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

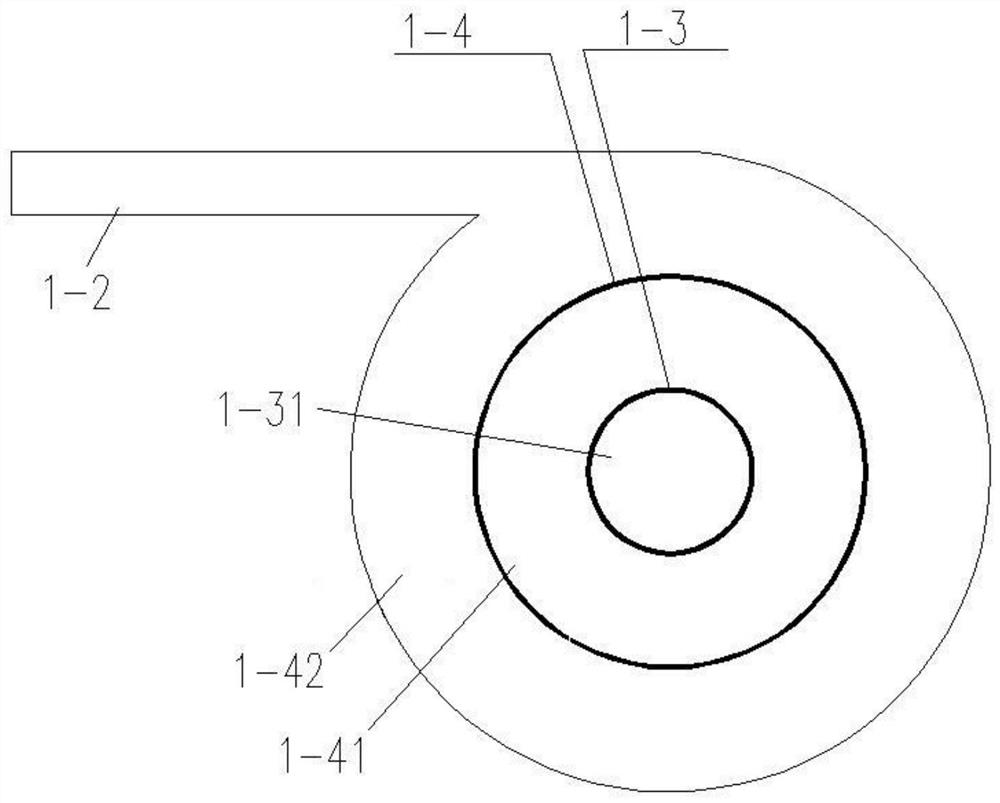

[0048] Such as figure 1 As shown, a sand-water separation system for efficient separation of sand in sewage, including a connected folded plate rheological type multi-directional flow sand water separator processing unit 1, a first heterogeneous new sand filter processing unit 2 and a second 2. Heterogeneous new sand filter processing unit 3;

[0049] Folded plate rheological type multi-directional flow sand water separator processing unit 1 includes a shell tube plate 1-1, a tangential water inlet pipe 1-2 located on one side of the shell tube plate, and two permeable inner tube plates 1 located on the upper side of the shell tube plate -3 and two permeable outer tube plates 1-4, a tangential outlet channel 1-5 located on the other side of the shell tube plate, the permeable inner tube plate 1-3 and the permeable outer tube plate 1-4 pass through the sloping plate 1 of the ring wall -6 connection, the tangential outlet channel 1-5 is located on the upper side of the sloping ...

Embodiment 2

[0069]This embodiment is a method for using the sand-water separation system for efficient separation of sand particles in sewage as in Embodiment 1, including the following steps:

[0070] S1: Sandy sewage enters the outer ring laminar flow zone 1-42 from the tangential water inlet pipe 1-2, and the water body undergoes tangential circulation movement to generate radial stratified laminar flow. In the outer ring laminar flow zone 1-42, the water body The sand particles in the radial direction are mainly affected by centrifugal force, pressure gradient force and drag force. The circular motion of the water body can make the sand particles move from the inside to the outside in the radial direction under the action of the centrifugal force, so that the density of each layer in the laminar flow changes. , while the pressure gradient force The direction opposite to the centrifugal force is not conducive to the separation of particles. Therefore, the outer cylinder plate of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com