A winding device for winding binding material

A material roll and winding technology, which is applied in the removal of binding materials, delivery of filamentous materials, packaging, etc., can solve the problem of messy available space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

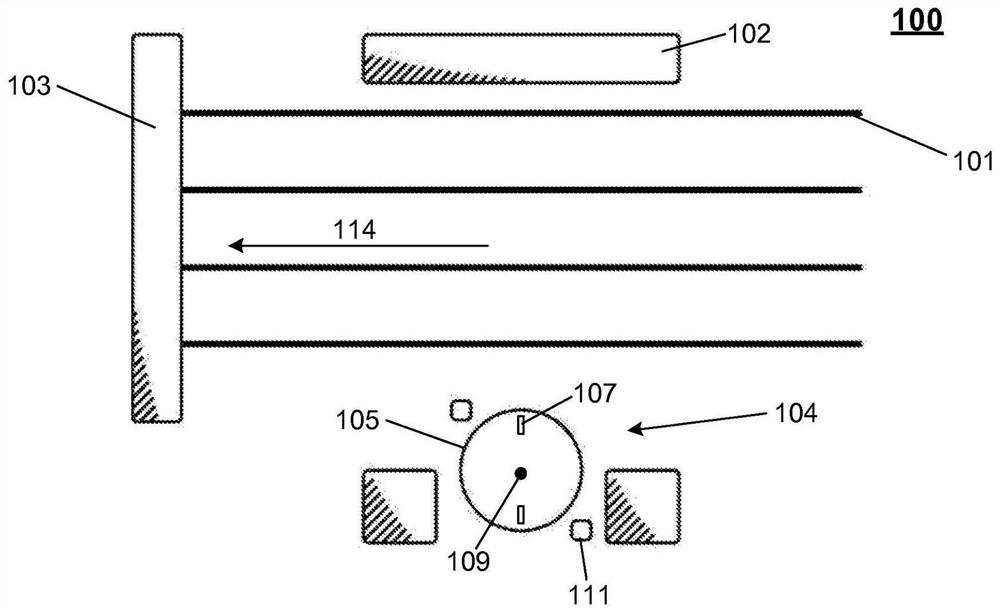

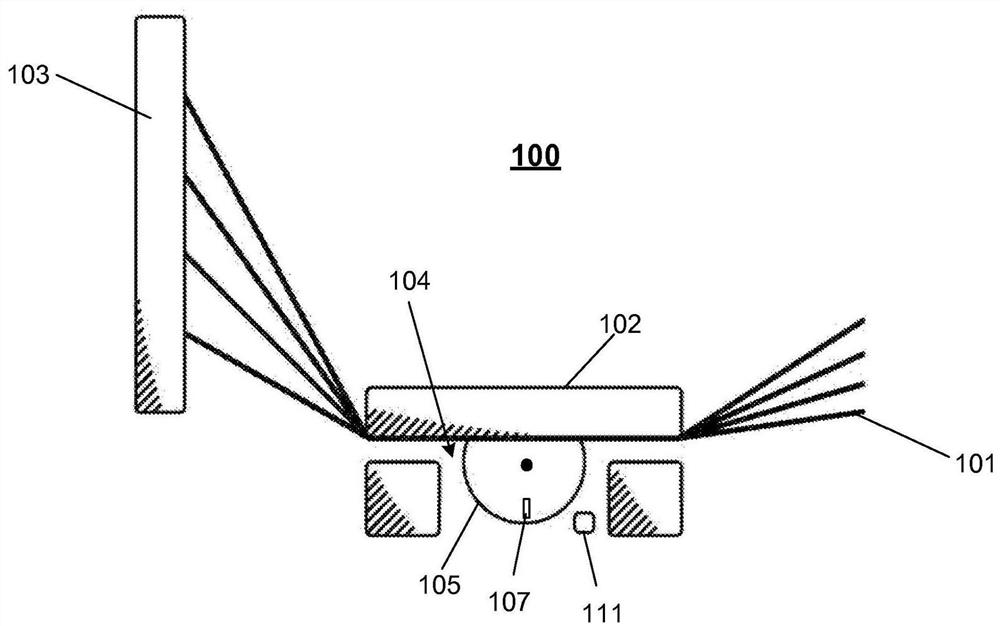

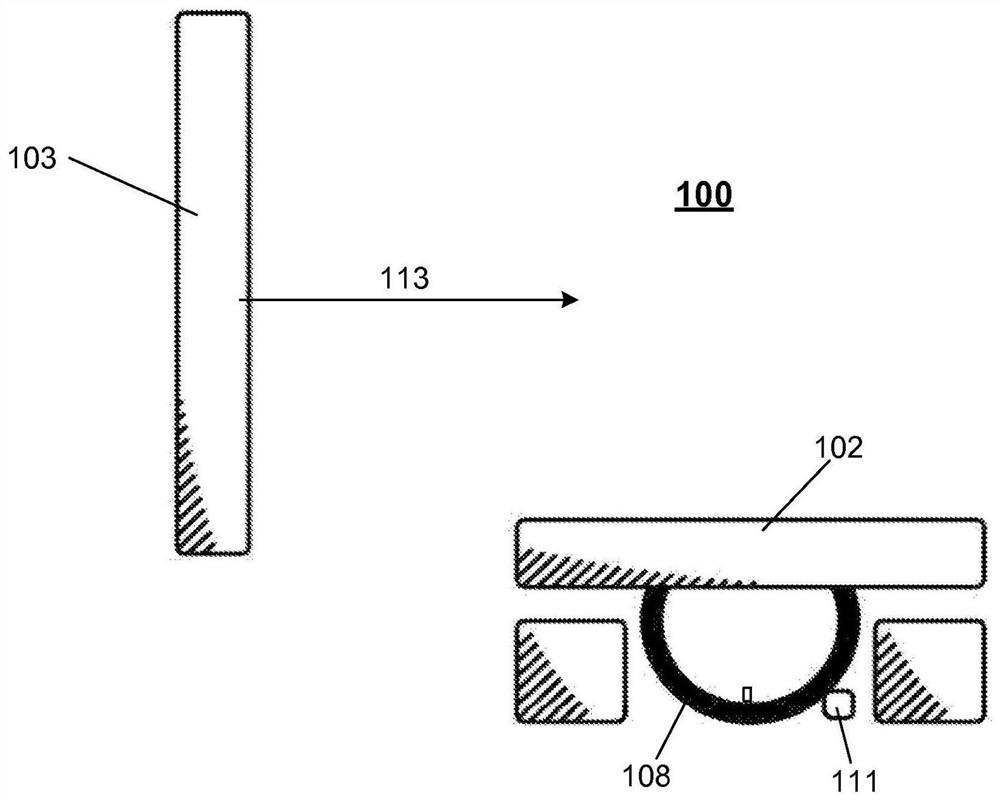

[0030] Figure 1 to Figure 5 The principle of an exemplary device 100 for winding binding material 101 in different modes of operation according to an advantageous embodiment of the invention is shown. in addition, Image 6 A side view of an exemplary device 100 according to an advantageous embodiment of the invention is shown.

[0031] The winding device 100 advantageously operates in conjunction with a gripping mechanism 103 which is typically pushed into an object, such as a bale (not shown), so that it can grip the binding material 101 . When the gripping mechanism 103 grips the binding material 101 from the bale (or other object), the gripping mechanism 103 is removed 114 from the bale together with the gripped binding material 101, as figure 1 shown. The gripping mechanism 103 may be arranged to interface with an external baler, or alternatively the binding material winding device 100 may comprise said gripping mechanism 103 . Furthermore, according to an embodiment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com