Heterogeneous temperature equalizing device

A device and heterogeneous technology, applied in the field of thermal management devices, can solve the problems of small heat flux and low vertical thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

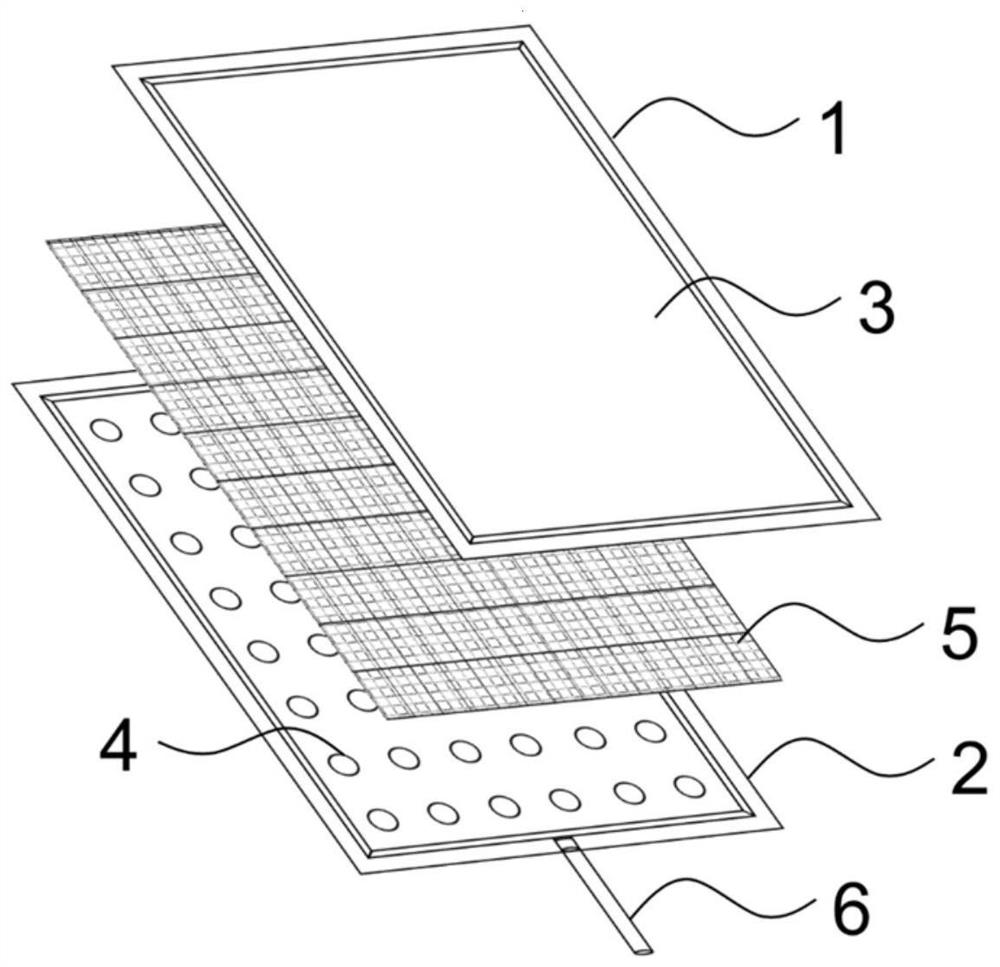

[0036] A heterogeneous temperature uniform device to achieve foldable and efficient temperature uniform heat dissipation, such as figure 1 As shown, there are two vapor chambers 101 on the left and right, and a copper soft connection 102 connecting the two vapor chambers 101 .

[0037] In this embodiment, the vapor chamber 101 includes a copper upper shell plate 1 and a lower shell plate 2, such as figure 2 As shown, the upper shell plate 1 and the lower shell plate 2 form a cavity for accommodating a liquid-absorbing core 5, and the liquid-absorbing core 5 is loaded with heat-conducting medium water. The plane area of a single vapor chamber is 25cm 2 , the thickness is 0.5mm.

[0038] Specifically, the following steps are used for assembly:

[0039] (1) Punching the copper foil of the raw material of the shell plate to obtain the upper shell plate 1 and the lower shell plate 2 with specific dimensions.

[0040] (2) The upper shell plate 1 and the lower shell plate 2 ob...

Embodiment 2

[0057] A heterogeneous temperature uniform device to achieve foldable and efficient temperature uniform heat dissipation, such as Figure 4 As shown, there are two vapor chambers 101 on the left and right, and a flexible connection 102 connecting the vapor chambers 101 .

[0058] In this embodiment, the vapor chamber 101 includes an aluminum upper shell plate 1 and a lower shell plate 2, the upper shell plate 1 and the lower shell plate 2 form a cavity for accommodating the liquid-absorbing core 5, and the liquid-absorbing core 5. Load heat conduction medium ethanol. The plane area of a single vapor chamber is 25cm 2 , How much is the thickness of 0.3mm.

[0059] Specifically, the following steps are used for assembly:

[0060] (1) Punching the aluminum foil of the raw material of the shell plate to obtain the upper shell plate 1 and the lower shell plate 2 with specific dimensions.

[0061] (2) The upper shell plate 1 and the lower shell plate 2 obtained in step (1) are...

Embodiment 3

[0077] The main structure of this embodiment is the same as that of Implementation 1, and the similarities will not be repeated here. The difference is that: Figure 5 The flexible connection used is a 6-strand copper braided rope as shown.

[0078] The diameter of the copper wire is 10 μm, and each bundle contains 100 copper wires; the radial thermal conductivity of the flexible connection composed of 6 copper wire braided ropes is 380W / mK.

[0079] In this embodiment, the soft connection is connected to the vapor chamber 101 by means of cold pressure welding.

[0080] The heterogeneous temperature uniform device of this embodiment was subjected to a heat conduction test and a folding test. After 10 hours of testing, the temperature difference between the two temperature chambers did not exceed 8°C.

[0081] The number of times of bending resistance is more than 1000 times. Under 90° bending, the temperature difference between the two vapor chambers does not exceed 9°C; unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com