Magnetofluid integrated crystal oscillator baffle switching mechanism

A switching mechanism, magnetic fluid technology, applied in liquid/fluid solid measurement, shielding, measurement devices, etc., can solve problems such as instability, uneven thickness of substrate coating, and crystal oscillator fouling crystal frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

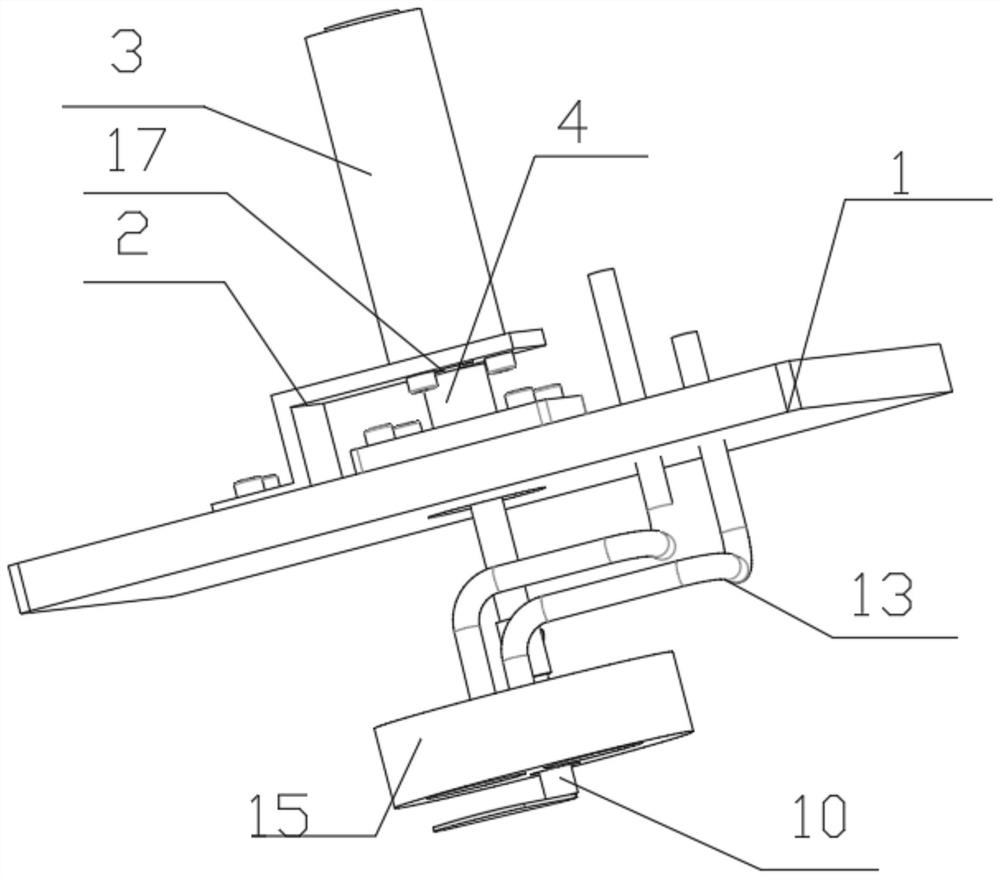

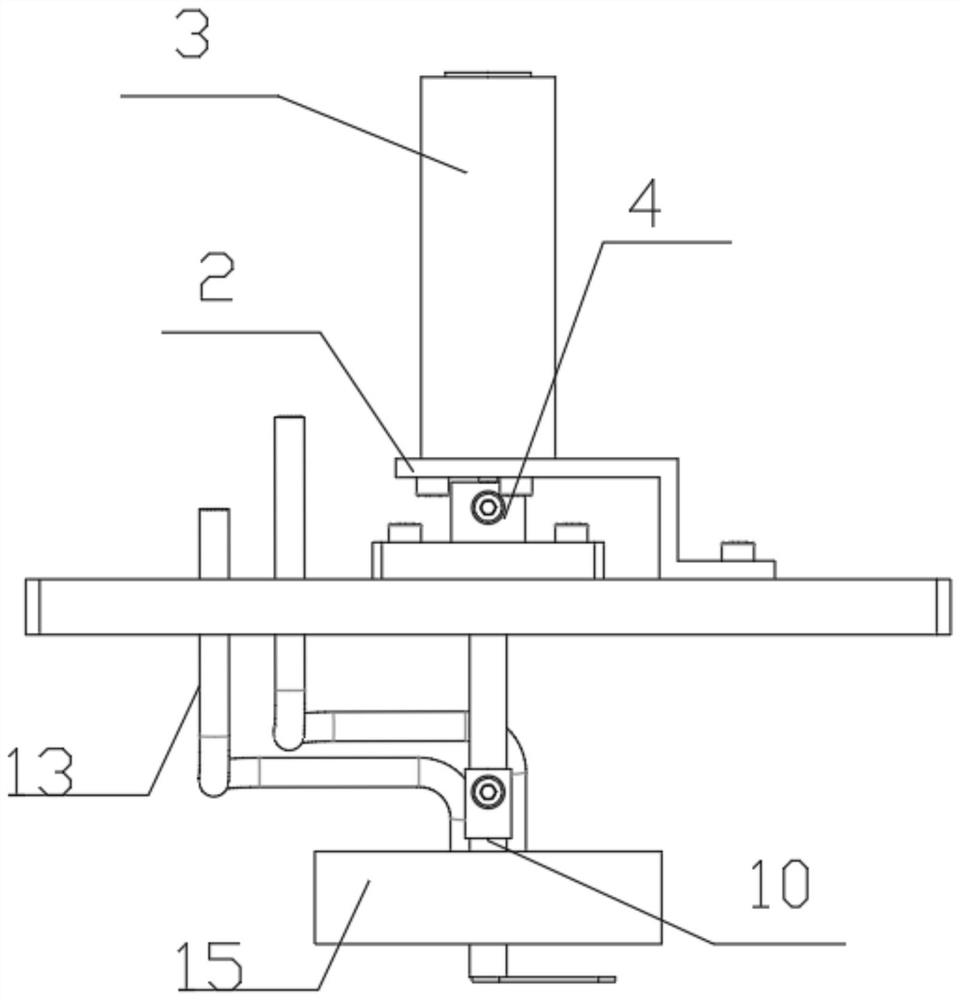

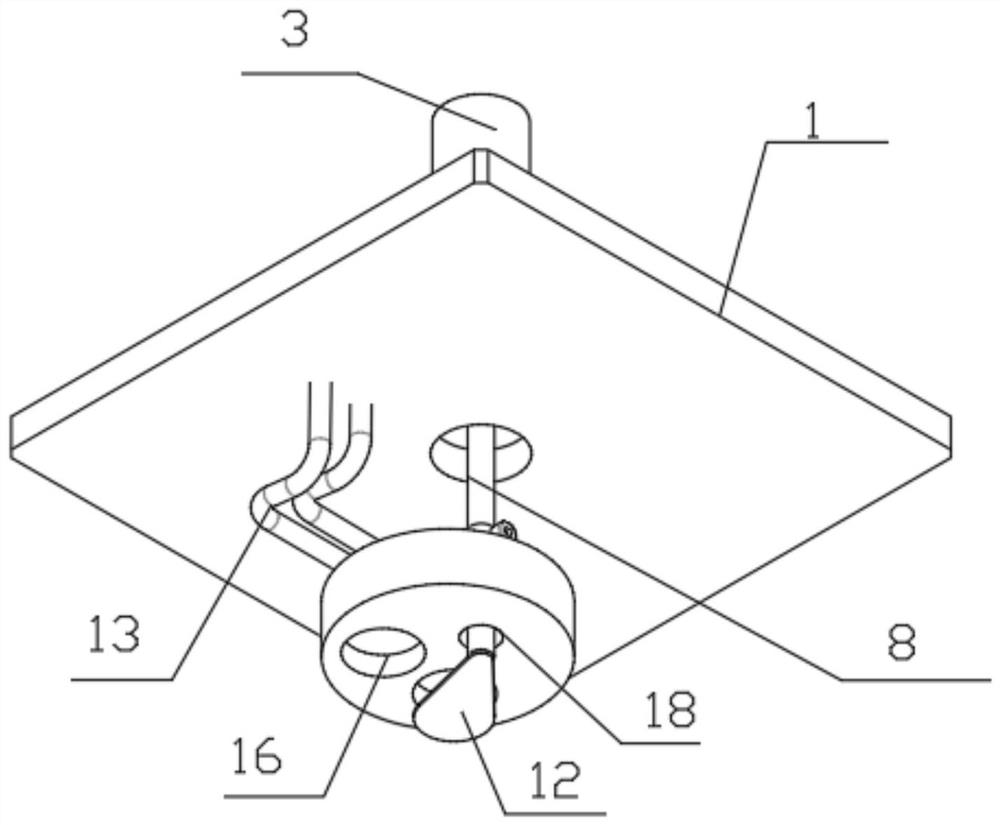

[0031]Such asfigure 1 As shown, the structural diagram of the magnetic fluid integrated crystal oscillating plate switching mechanism of the present invention;figure 2 As shown, the main view of the magnetic fluid integrated crystal oscillating plate switching mechanism of the present invention;image 3 As shown, the proposal view of the magnetic fluid integrated crystal oscillating plate switching mechanism of the present invention;Figure 4 As shown, it is an explosion of the magneto-fluid-integrated crystal oscillating plate switching mechanism of the present invention;Figure 5As shown, the explosion diagram of the magnetic fluid integrated crystal oscillating plate switching mechanism of the present invention is shown.

[0032]A magnetic fluid integrated crystal hierarch plate switching mechanism, comprising: vapor deposition cavity top plate 1, bracket 2, cylinder 3, magnet body 4, connecting member 9, shutter 10, and crystal phosso 15, characterized in: Two detecting holes 16 are p...

Embodiment 2

[0044]Such asfigure 1 As shown, the structural diagram of the magnetic fluid integrated crystal oscillating plate switching mechanism of the present invention;figure 2 As shown, the main view of the magnetic fluid integrated crystal oscillating plate switching mechanism of the present invention;image 3 As shown, the proposal view of the magnetic fluid integrated crystal oscillating plate switching mechanism of the present invention;Figure 4 As shown, it is an explosion of the magneto-fluid-integrated crystal oscillating plate switching mechanism of the present invention;Figure 5As shown, the explosion diagram of the magnetic fluid integrated crystal oscillating plate switching mechanism of the present invention is shown.

[0045]A magnetic fluid integrated crystal hierarch plate switching mechanism, comprising: vapor deposition cavity top plate 1, bracket 2, cylinder 3, magnet body 4, connecting member 9, shutter 10, and crystal phosso 15, characterized in: Two detecting holes 16 are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com