Fixing device for bolt assembly automatic production and working method thereof

A technology of fixing device and working method, which is applied to workpiece clamping device, testing material strength by applying stable torsion force, manufacturing tools, etc., can solve the problems of increased cost, poor practicability, trouble in daily use, etc., and achieve the effect of increasing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

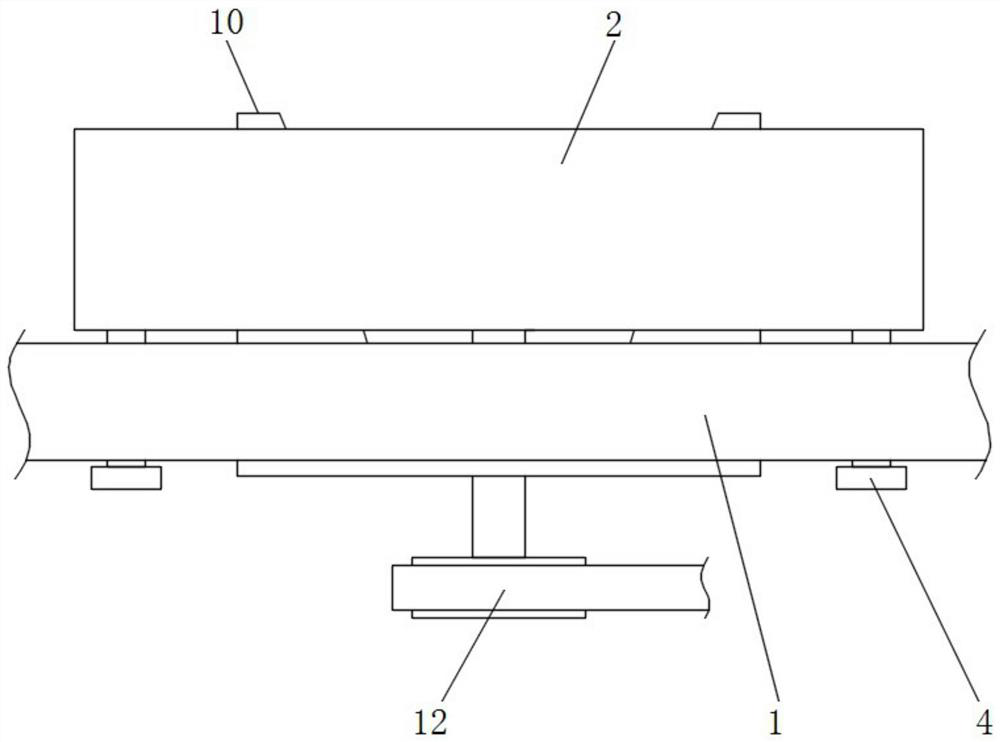

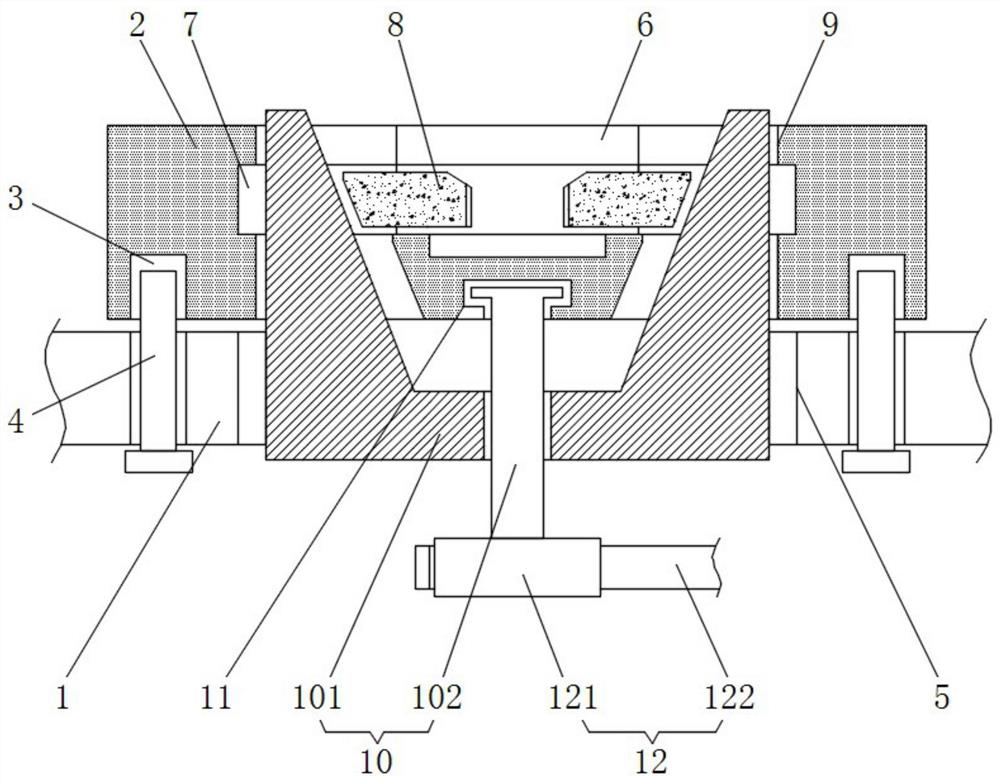

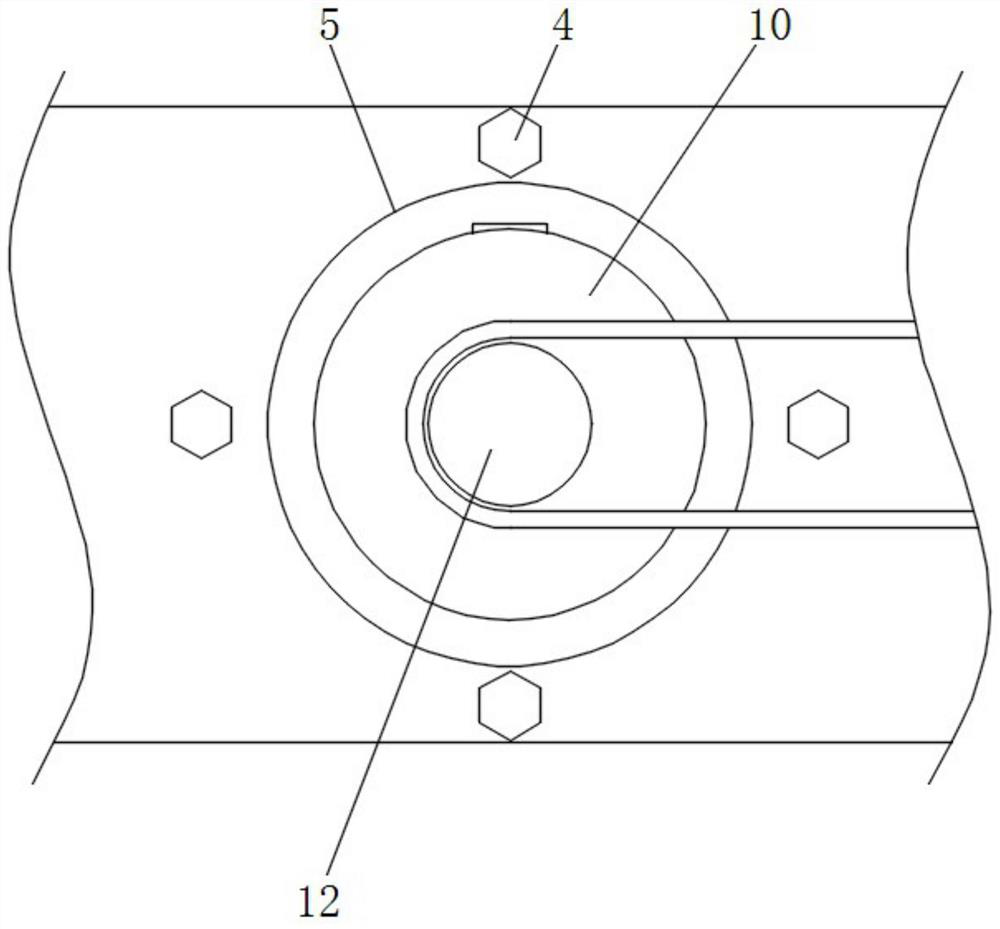

[0023] see Figure 1~4 , in an embodiment of the present invention, a bolt assembly automatic production fixing device and its working method, comprising a base plate 1 and a base 2 for fixing the test bolts, the bottom of the base 2 for fixing the test bolts is provided with a threaded hole for fixing the base 2 3. The lower surface of the bottom plate 1 is provided with fixing bolts 4 for fixing the base 2 on the bottom plate 1. There are four fixing bolts 4 to fix the base 2 firmly. The base 2 is located on the upper surface of the bottom plate 1, and the top of the fixing bolts 4 It penetrates through the bottom plate 1 and extends to the top of the bottom plate 1 and is threadedly connected with the inner wall of the threaded hole 3. The lower surface of the bottom plate 1 is provided with a through groove A5 for the movement of the four-claw block 101, and the lower surface of the base 2 is opened at the position of the through groove A5. There is a placement groove 6 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com