Pressure drop flow testing system and method for testing pipeline flame arrester

A technology of flow test and flow test device, which is applied in the field of flame arrester performance test, can solve the problems of large error, inability to control the maximum value of pressure, complicated process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

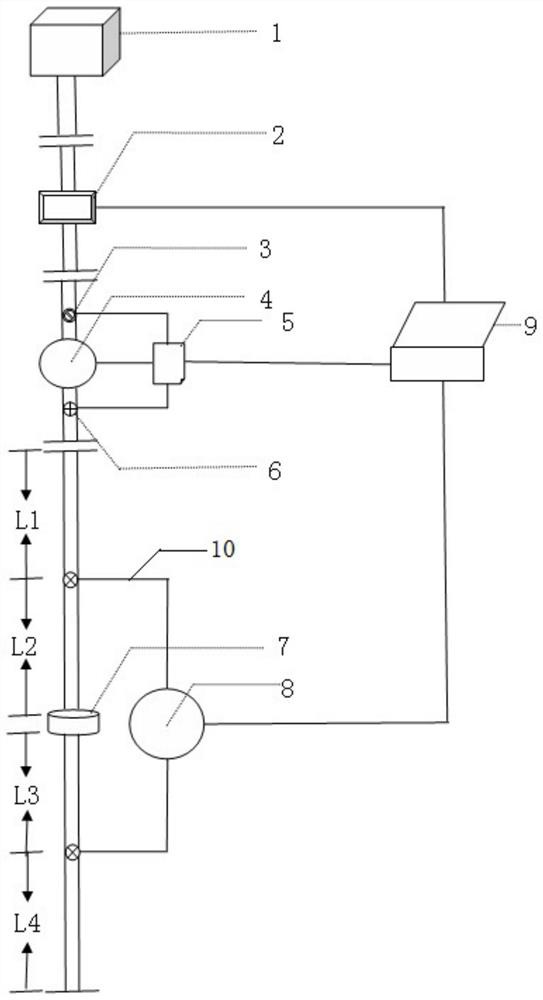

[0031] Such as figure 1 As shown, a pressure drop flow test system for pipeline flame arrester testing, including an air supply device 1, a pressure control device, a pressure drop flow test device and a controller, an air supply device 1, a pressure control device and a pressure drop flow test The devices are connected sequentially. The air supply device 1 can be an air compressor or a fan, and is mainly used to directly provide air for the system, cancel the pressure storage space, and reduce potential safety hazards; the controller is a computer 9,

[0032] The pressure control device includes an electronic pressure controller 2 , a pressure transmitter 3 , a flow meter 4 , an integrator 5 , and a thermocouple 6 . The pressure drop flow test device includes pipeline flame arrester 7 and electronic pressure gauge 8, air supply device 1, electronic pressure controller 2, pressure transmitter 3, flow meter 4, and pipeline flame arrester 7 are sequentially connected through pi...

Embodiment 2

[0037] This embodiment provides a method for testing a pressure drop flow test system for a pipeline flame arrester, which is performed using the pressure drop flow test system described in Embodiment 1, including the following steps:

[0038] (1) Open the air supply device 1 to deliver air with pressure in the pipeline;

[0039] (2) Regulate the electronic pressure controller 2 through the computer 9, adjust the gas pressure through the electronic pressure controller 2, and provide air with a stable pressure for the follow-up pipeline, that is, the pressure of the connected pipeline after the electronic pressure controller 2 can be controlled by the electronic pressure controller 2 control, regulated by computer 9;

[0040] (3) The data measured by the air in the pipeline through the pressure transmitter 3, the flowmeter 4, and the thermocouple 6 are converted at the calculator 5, and finally the flow result under the standard condition is fed back to the computer 9, which ca...

Embodiment 3

[0045] Take the pressure drop flow test of a pipeline flame arrester with a nominal diameter of DN50 as an example:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com