High-density polymer grouting reinforcement method for roadbed at sinking position of bridge and culvert butt strap

A grouting reinforcement and high-density technology, applied in the direction of roads, roads, road bottom, etc., can solve problems that even exceed 60cm, settlement fractures at bridge heads and abutment backfill, and no further in-depth research on the grouting mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

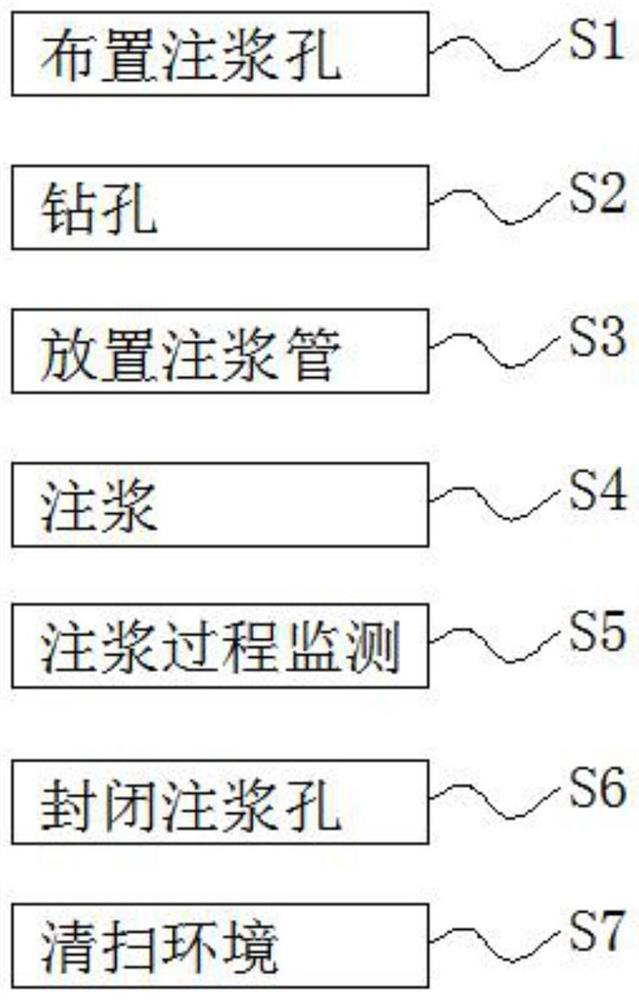

[0028] see figure 1 , a method for reinforcing a subgrade with high-density polymer grouting at the subsidence of bridge and culvert slabs, comprising the following steps:

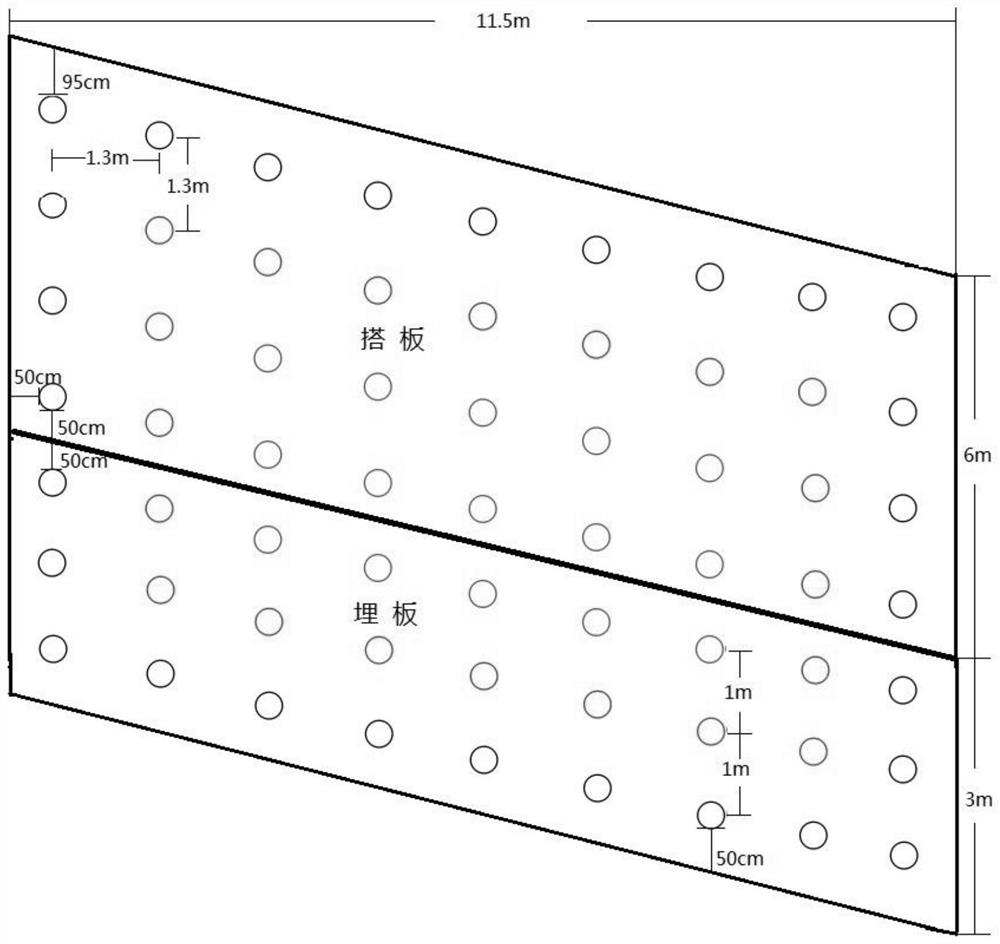

[0029] S1. Layout of grouting holes: arrange the grouting holes according to the site conditions, such as figure 2 As shown, the range of grouting hole distance is 1m-1.3m;

[0030] S2. Drilling: use a hollow drill to drill through the cement panel and the road base, and the drilling is divided into shallow drilling and deep drilling;

[0031] S3. Placing grouting pipes: The roadbed under the slab is reinforced by grouting, which is divided into two layers, located at 1.3m and 2m respectively, and the placement depths of the grouting pipes are 1.3m and 2m respectively;

[0032] S4. Grouting: if image 3 As shown, the slabs of exposed bridges and culverts are composed of slabs and buried slabs. The lengths of the slabs are 6m and 3m respectively, the width of the half-width driveway is 11.5m, and the co...

Embodiment 2

[0043] A high-density polymer grouting reinforcement method for subgrades at subsidence of bridge and culvert slabs, comprising the following steps:

[0044] S1. Layout of grouting holes: arrange the grouting holes according to the site conditions, such as figure 2 As shown, the range of grouting hole distance is 1m-1.3m;

[0045] S2. Drilling: use a hollow drill to drill through the cement panel and the road base, and the drilling is divided into shallow drilling and deep drilling;

[0046] S3. Placing grouting pipes: The roadbed under the slab is reinforced by grouting, which is divided into two layers, located at 1.3m and 2m respectively, and the placement depths of the grouting pipes are 1.3m and 2m respectively;

[0047] S4. Grouting: if image 3 As shown, the slabs of exposed bridges and culverts are composed of slabs and buried slabs. The lengths of the slabs are 6m and 3m respectively, the width of the half-width driveway is 11.5m, and the construction area is about...

Embodiment 3

[0058] After adopting the method described in Example 1 for construction, we inspected the effect of grouting construction:

[0059] Measure the lifting amount of the subsidence board: to ensure that the grouting material fills the void in the subgrade within the grouting depth range of 2m, and has the effect of reinforcing the soft subgrade. During grouting construction, for areas with large subsidence, the uplift of each grouting point shall be <1mm. Measured after grouting, the accumulative uplift of the slab is about 2cm in the area with the largest subsidence. It proves that this grouting construction has obvious roadbed reinforcement, filling and lifting effects.

[0060] After the grouting construction, we drilled core samples in the emergency parking lane and the driving lane respectively, and took out 2 core samples in total. According to the core samples taken out, it can be judged that the structure of the upper layer (10cm) of the board, the board (25cm), and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com