Application of marinobacterium in preparation of polyhydroxyalkanoate

A technology of polyhydroxyalkanoate and sea bacteria, which is applied in the field of microbiology and bioengineering, and can solve the problems of restricting large-scale production and application and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Embodiment 1, utilize acetic acid as carbon source to produce polyhydroxyalkanoate

[0073] 1. Aseptically prepare the seed solutions of three strains of M. nitratireducens, M. sediminicola and M. zhoushanense respectively.

[0074] (1) Activation of bacteria

[0075] Take a glycerol tube of strains stored in a -80°C refrigerator, streak and inoculate it on a TYS medium plate, and incubate at 37°C for 24 hours.

[0076] (2) Preparation of seed solution

[0077] Pick a single colony from the plate that completed step (1), inoculate it in liquid TYS medium, and cultivate it with shaking at 37°C and 200rpm for 12-16h.

[0078] 2. Prepare liquid TYS medium, add acetic acid to a final concentration of 10g / L, and adjust the pH to 7.5.

[0079] 3. The seed liquid obtained in step 1 (2) in Example 1 was inoculated respectively in liquid TYS medium containing 10 g / L acetic acid (to Acetic acid was added to the liquid TYS medium until the content of acetic acid was 10g / L (the...

Embodiment 2

[0089] Embodiment 2, utilize propionic acid as carbon source to produce polyhydroxyalkanoate

[0090] The specific operation is according to Example 1 of the present invention, the difference is that the medium in step 3 is a liquid TYS medium containing 10 g / L propionic acid. Step 5 detects poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV for short).

[0091] The PHBV output algorithm is: PHBV output = PHB output + PHV output, where:

[0092] PHB yield=(peak area of PHB in sample / peak area of internal standard in sample)×[(peak area of internal standard in standard / peak area of PHB in standard)×(mass of standard×0.866)] / mass of esterification of sample× dry cell weight

[0093] PHV yield=(peak area of PHV in sample / peak area of internal standard in sample)×[(peak area of internal standard in standard / peak area of PHV in standard)×(mass of standard×0.134)] / mass of esterification of sample× dry cell weight

[0094] Polymer content is defined as the ratio o...

Embodiment 3

[0100] Embodiment 3, utilize butyric acid as carbon source to produce polyhydroxyalkanoate

[0101] The specific operation is as in Example 1 of the present invention, except that the medium in step 3 is a liquid TYS medium containing 10 g / L butyric acid.

[0102] The dry cell weight and PHB accumulation of the three strains using butyric acid are shown in Table 3:

[0103] Table 3 The cell growth and PHB accumulation of three kinds of marine bacteria when using butyric acid as carbon source

[0104]

[0105] When butyric acid was used as the carbon source, the dry cell weights of M. nitratireducens, M. sediminicola and M. zhoushanense were 5.06g / L, 3.25g / L and 1.92g / L, respectively, and the polyhydroxyalkanoate accumulated in the cells was The yields of poly-3-hydroxybutyrate were 3.38g / L, 2.07g / L and 0.63g / L, respectively, and the mass fractions of PHB in dry cell weight were 66.81%, 58.39% and 32.49%.

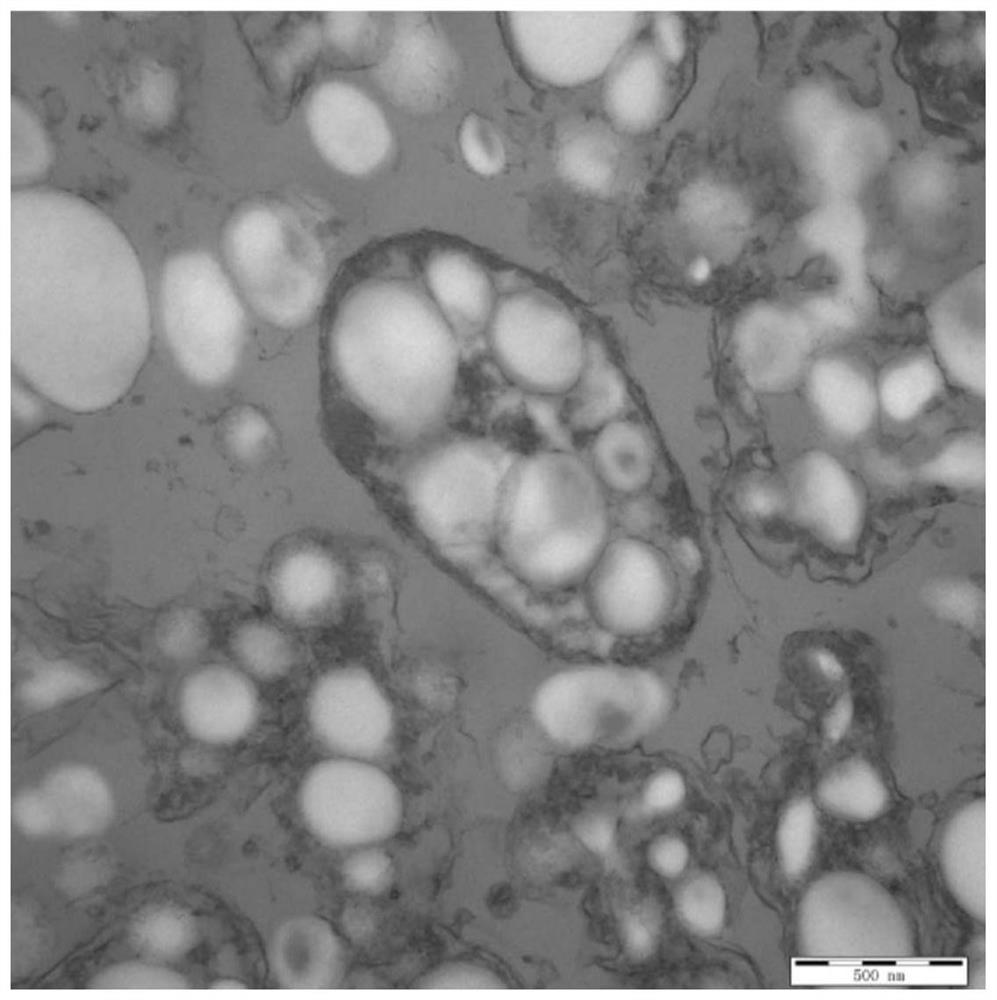

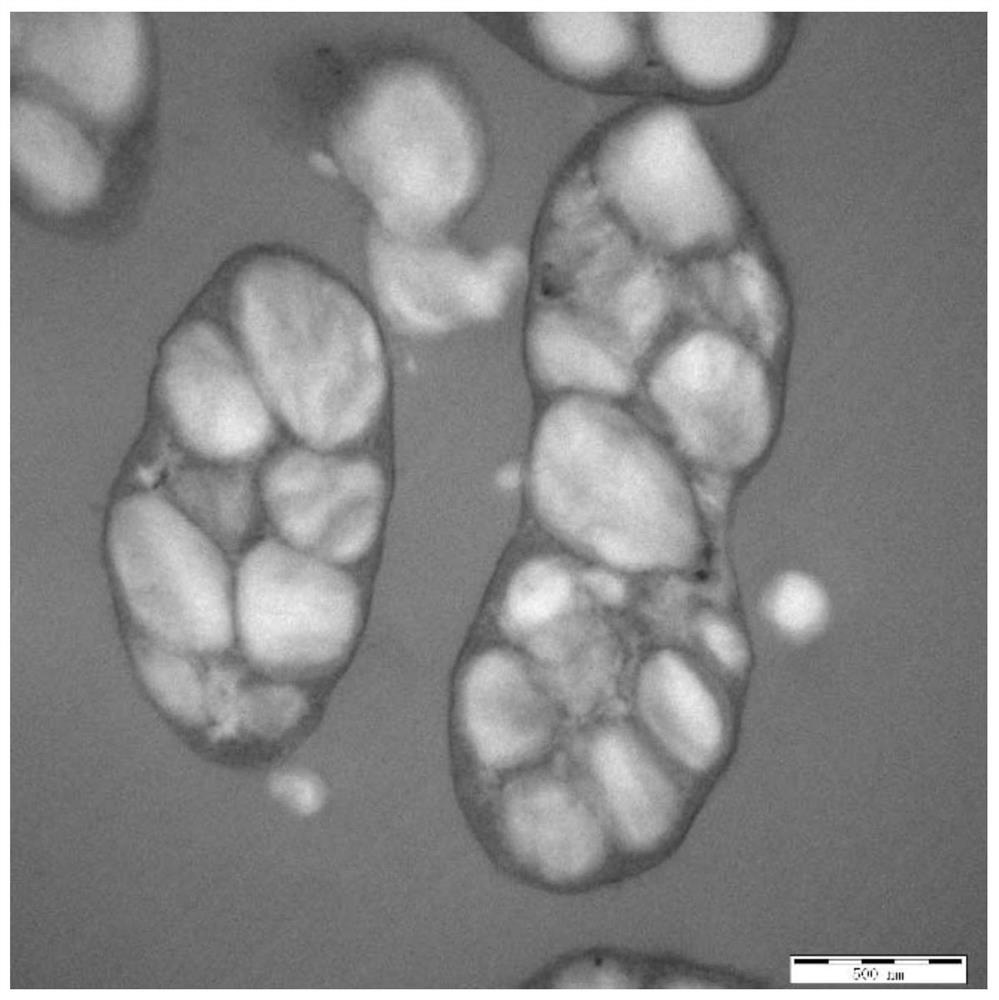

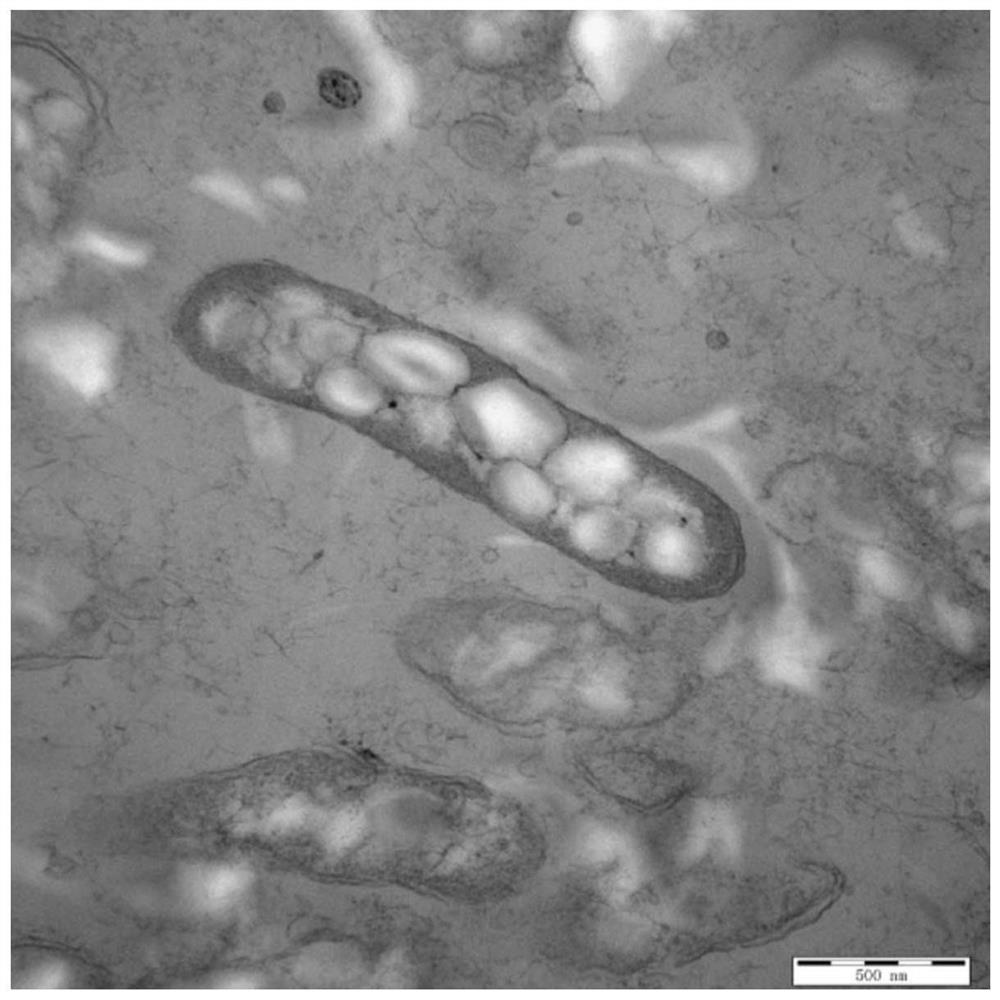

[0106] In addition, utilize transmission electron microscope to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry cell weight | aaaaa | aaaaa |

| Dry cell weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com