High-mixing-amount solid waste grouting material for mine limestone aquifer transformation and method

A grouting material with a large amount of technology, applied in the field of building materials, can solve problems such as unsuitability, reduced viscosity, and low gel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

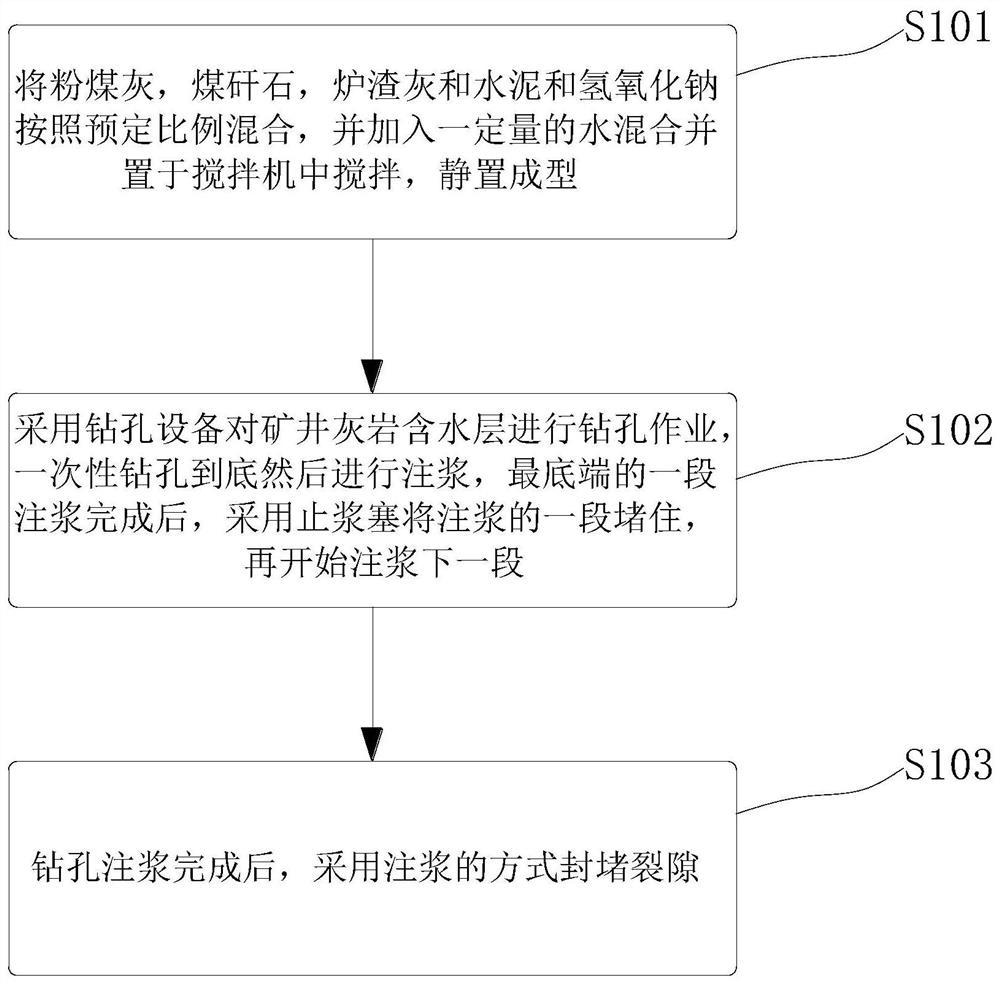

Method used

Image

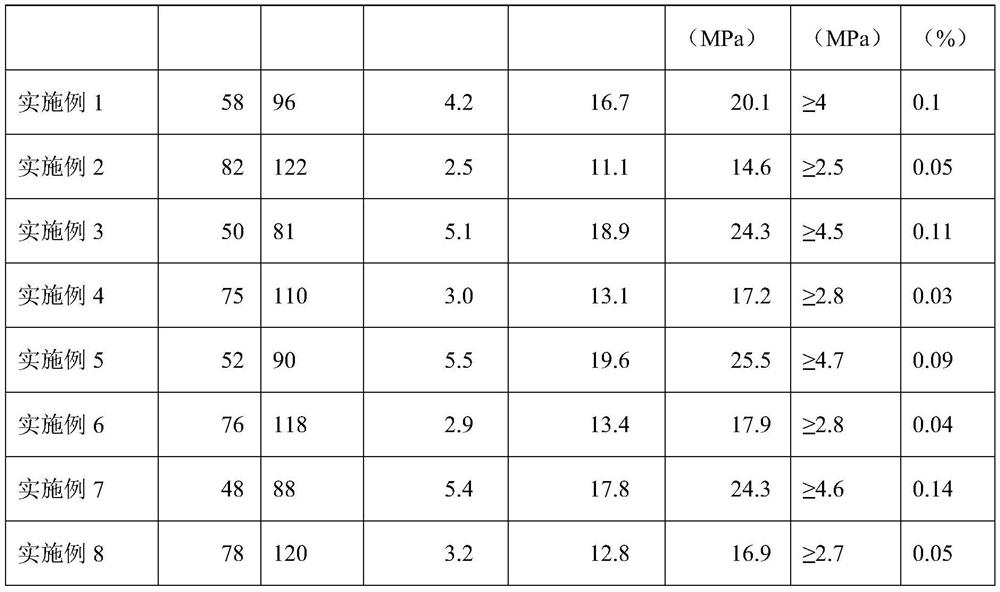

Examples

Embodiment 1

[0024] A large-volume solid waste grouting material for the reconstruction of limestone aquifers in mines, comprising the following raw material formula in parts by mass:

[0025] 40 parts of fly ash, 30 parts of coal gangue, 20 parts of slag ash, 10 parts of cement and 3 parts of alkali activator sodium hydroxide. 100 parts of water, wherein, fly ash, coal gangue, and slag ash all come from industrial solid waste.

[0026] The fly ash is waste produced in coal mines, with a particle size of 60 mesh. The fly ash used is the waste produced by coal mines, fully utilizes the industrial waste, can reduce the impact on the environment, has low cost and is easy to prepare.

[0027] The coal gangue is waste produced in coal mines, and the particle size is 10 mesh. The coal gangue used is the waste produced by coal mines, fully utilizes the industrial waste, can reduce the impact on the environment, has low cost and is easy to prepare.

[0028] The slag ash is waste produced in coa...

Embodiment 2

[0035] A large-volume solid waste grouting material for the reconstruction of limestone aquifers in mines, comprising the following raw material formula in parts by mass:

[0036] 40 parts of fly ash, 30 parts of coal gangue, 20 parts of slag ash, 10 parts of cement and 3 parts of alkali activator sodium hydroxide. 150 parts of water, of which, fly ash, coal gangue, and slag ash all come from industrial solid waste.

[0037] The fly ash is waste produced in coal mines, with a particle size of 50 mesh. The fly ash used is the waste produced by coal mines, fully utilizes the industrial waste, can reduce the impact on the environment, has low cost and is easy to prepare.

[0038] The coal gangue is waste produced in coal mines, and the particle size is 20 mesh. The coal gangue used is the waste produced by coal mines, fully utilizes the industrial waste, can reduce the impact on the environment, has low cost and is easy to prepare.

[0039] The slag ash is waste produced in co...

Embodiment 3

[0044] A large-volume solid waste grouting material for the reconstruction of limestone aquifers in mines, comprising the following raw material formula in parts by mass:

[0045] 30 parts of fly ash, 30 parts of coal gangue, 20 parts of slag ash, 20 parts of cement and 3 parts of alkali activator sodium hydroxide. 100 parts of water, wherein, fly ash, coal gangue, and slag ash all come from industrial solid waste.

[0046] The fly ash is waste produced in coal mines, with a particle size of 80 mesh. The fly ash used is the waste produced by coal mines, fully utilizes the industrial waste, can reduce the impact on the environment, has low cost and is easy to prepare.

[0047] The coal gangue is waste produced in coal mines, and the particle size is 10 mesh. The coal gangue used is the waste produced by coal mines, fully utilizes the industrial waste, can reduce the impact on the environment, has low cost and is easy to prepare.

[0048] The slag ash is waste produced in coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com