A structure for integrated installation of front body and its manufacturing method

A manufacturing method and technology of front body, applied in the directions of superstructure, superstructure sub-assembly, vehicle parts, etc., can solve the problems of increased production cost, extremely high mold requirements, and many parts, etc., to achieve convenient processing, cost control, Highly integrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

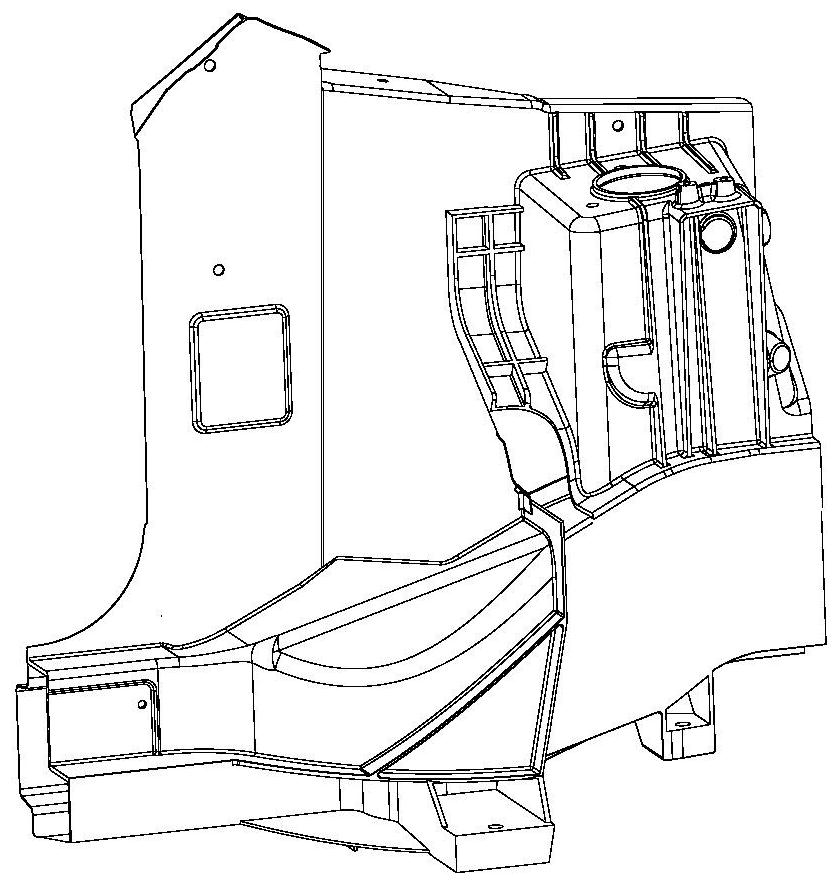

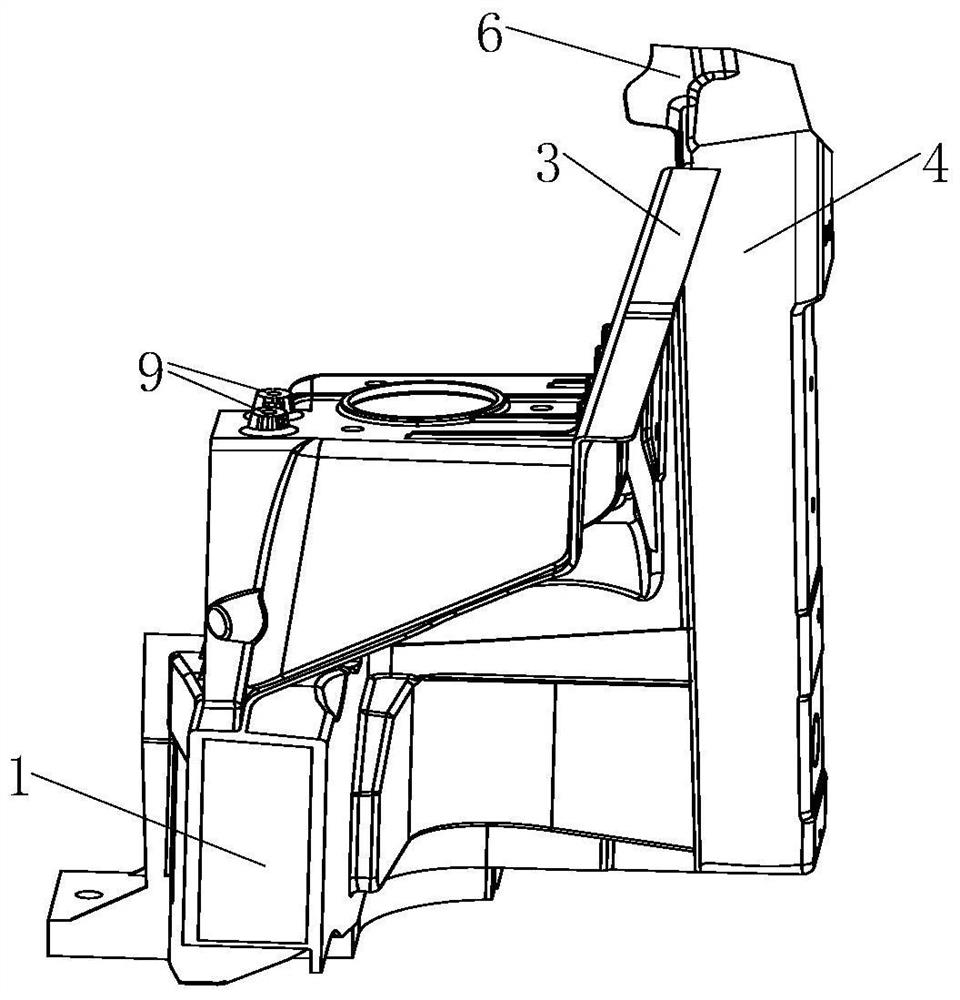

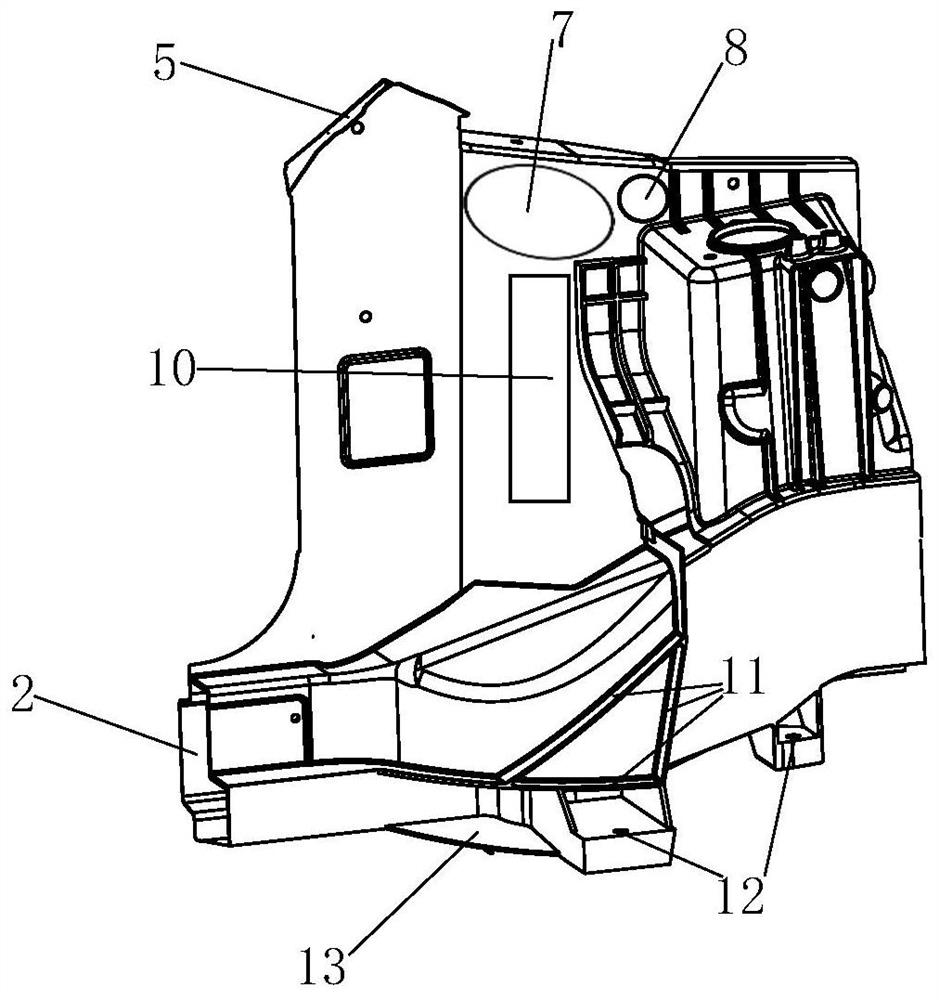

[0044] Figure 1-3 The structure used for the integrated installation of the front body is shown, which is a cavity structure formed by aluminum alloy casting, which has:

[0045] The front longitudinal beam connection part, the front longitudinal beam connection part has a front longitudinal beam connection port 1;

[0046] A sill beam connection part, the sill beam connection part has a sill beam connection port 2;

[0047] The upper side beam installation part, the upper side beam installation part has a first upper side beam installation surface 3 for connecting the upper surface of the upper side beam; a second upper side beam installation surface 4 for connecting the rear end of the upper side beam;

[0048] A-pillar connecting portion, the A-pillar connecting portion has an A-pillar connecting port 5;

[0049] The lower beam installation part of the front windshield, the lower beam installation part of the front windshield has the lower beam installation surface 6 of th...

Embodiment 2

[0070] The present invention also relates to a manufacturing method for a structure used for the integrated installation of the front body, which adopts an oxygen-filled die-casting method to form the structure, and the specific steps are:

[0071] S1: Preheat the mold first, keep the preheating temperature around 200°C, put the smelted aluminum alloy material into the mold; preheating is mainly to prevent the molten metal from being suddenly cooled and losing fluidity, resulting in molding failure or even The molding is successful, but there will be cracks or gaps on the surface of the part in the later stage;

[0072] S2: Then close the mold to close the mold to form the cavity and runner, and inject dry oxygen into the injection chamber and cavity of the die-casting mold through the injection hole to replace the air and other gases in it. When the aluminum alloy liquid is pressed When entering the pressure chamber and die-casting mold cavity, it reacts with oxygen to genera...

Embodiment 3

[0076] The invention relates to a structure for the integrated installation of the front body, which is an aluminum alloy casting, and specifically includes a front longitudinal beam connection port, a sill beam connection port, an A-pillar connection port, a firewall front baffle beam connection port, and a water tank installation surface , The installation surface of the front bulkhead of the firewall, the installation surface of the lower beam of the front windshield, the installation surface of the upper longitudinal beam, the installation surface of the front floor, the installation hole of the sub-frame, and the installation hole of the front cabin reinforcement beam.

[0077] A structure used for the integrated installation of the front body of the present invention not only serves to connect the front compartment and the cockpit, but also bears the impact of the frontal collision of the vehicle, protects the passenger compartment from deformation, and prevents the wheels...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com