Automatic cooling and fire extinguishing charging pile

An automatic cooling and charging pile technology, which is applied in electric vehicle charging technology, charging stations, electric vehicles, etc., can solve problems such as spontaneous combustion of charging piles, increased heat of components, and elevated temperature of piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

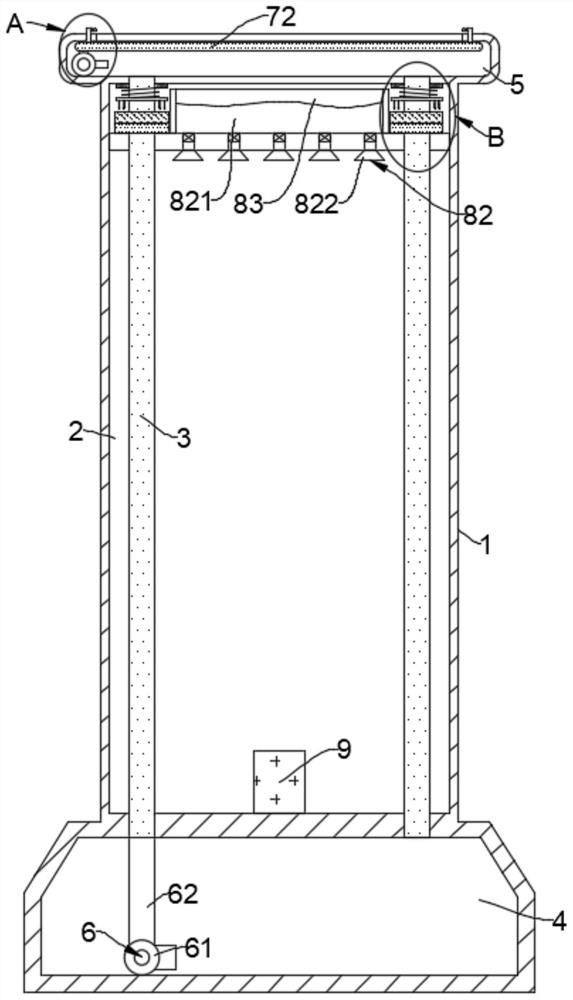

[0026] like Figure 1-6 As shown, a charging pile for automatic cooling and fire extinguishing includes a pile body 1, a cavity 2 is arranged in the pile body 1, and a plurality of vertical heat absorbing parts 3 are fixedly connected in the cavity 2, and the heat absorbing parts 3 are fixed by The cylinder 31 and the cooling plate 32 are composed of a plurality of cooling plates 32 and are vertically arranged. The cooling plate 32 is evenly and fixedly connected to the outside of the fixed cylinder 31, and the fixed cylinder 31 is fixedly connected to the upper top wall and the lower bottom wall of the cavity 2. .

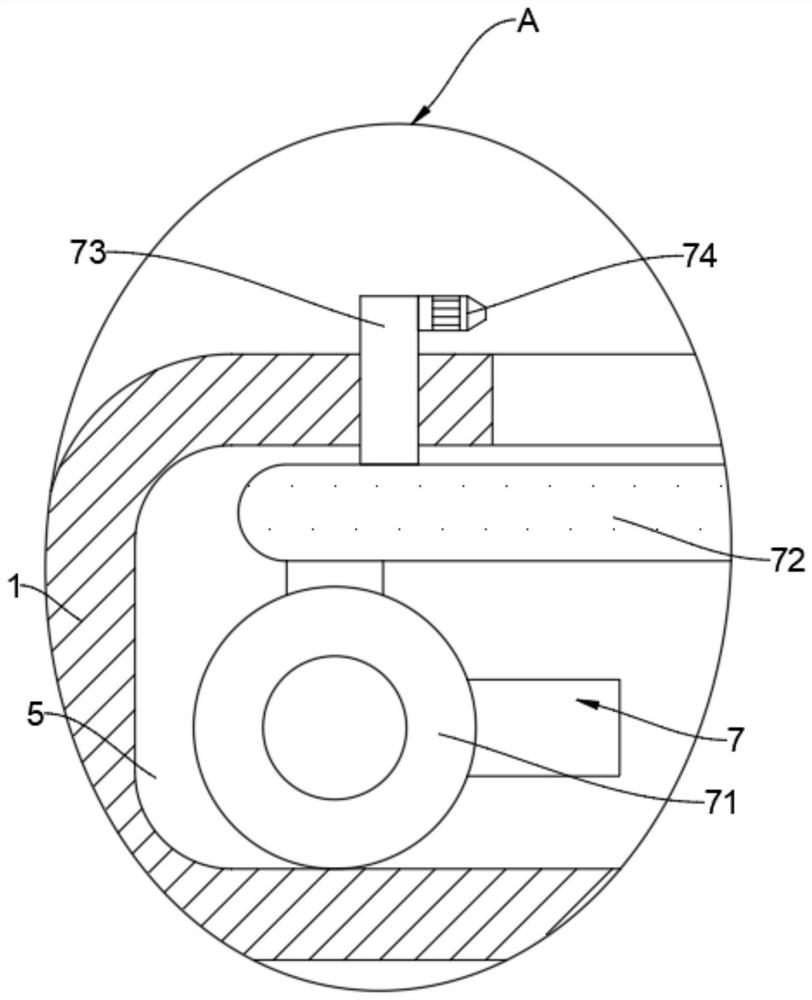

[0027] The bottom end of the heat absorbing part 3 runs through the cavity 2 and communicates with the water storage chamber 4. The top end of the heat absorbing part 3 is connected with the sump 5. The top of the sump 5 is a slotted struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com