Composite self-adhesive dimming film

A light-adjustable film and composite technology, applied in the field of light-adjustable film, can solve problems such as easy to scratch, easy to stick to dust, and affect the appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

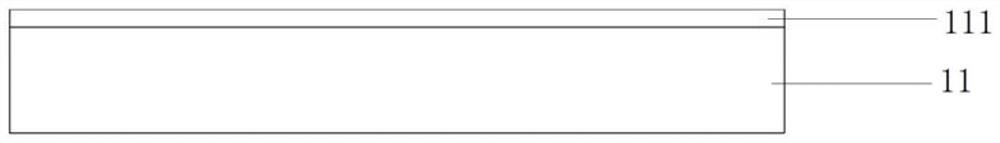

[0027] Such as figure 1 As shown, this embodiment is a composite self-adhesive dimming film, including a first PET substrate 11 and a smooth coating 111 coated on the first PET substrate 11 . In this embodiment, the smooth coating 111 on the PET base material can pass the pencil hardness test, so it can not be scratched in daily cleaning, and has anti-oil, anti-fingerprint and other effects. Even if it is exposed for a long time in this embodiment , It is not easy to get dust, fingerprints, etc., and it will not cause scratches when scrubbing, and it can maintain a certain degree of practicality and aesthetics.

[0028] Further, the smooth coating 111 includes: a coating formed by adding perfluoropolyether-modified acrylate to UV glue. The smooth coating 111 is added with perfluoropolyether modified acrylate, which can achieve a smooth effect, and the smooth layer can reach a hardness of 3-8H to prevent scratches; the experimental test water drop angle can reach more than 108...

Embodiment 2

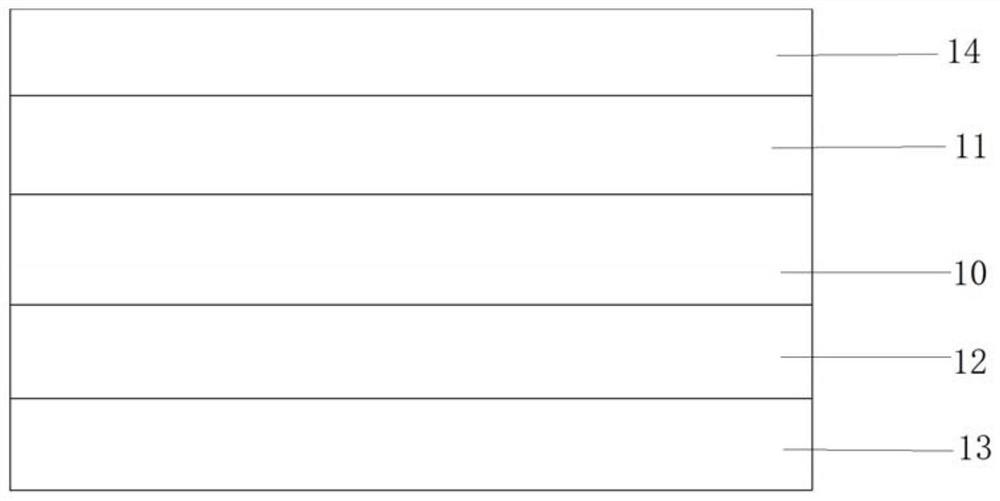

[0032] Such as figure 2 As mentioned above, this embodiment further includes a silicone glue layer 14 on the basis of the first embodiment above, and the silicone glue layer 14 is coated on the slippery coating 111 (not shown in the figure). The silicone glue layer 14 can protect the smooth coating 111 .

[0033] Specifically, an 8-10 μm silicone glue layer 14 is coated on the slippery coating 111 through dimples, wherein the peeling force is 3-5 grams. Further, the above-mentioned coating thickness of the silicone glue layer 14 may be 8 μm, 8.5 μm, 9 μm, 9.5 μm or 10 μm, etc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Drop angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com