Bearing installer of small cabin and method for installing bearing by adopting installer

A technology of a mounter and a bearing, applied in the field of machinery, can solve the problems of mechanical damage to the cabin and the shaft sleeve, inability to meet the assembly requirements, and high assembly accuracy requirements, and achieve the effects of simple structure, uniform and symmetrical pressing force, and high assembly accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

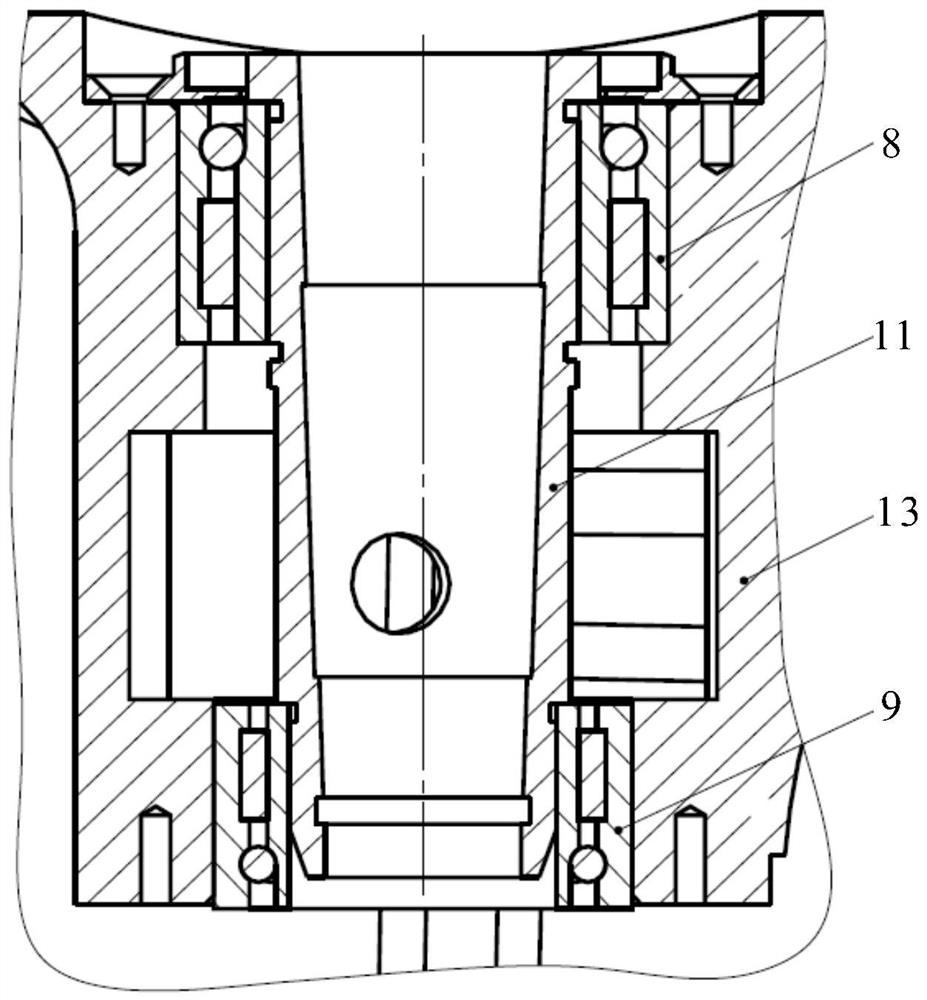

[0056] The assembly of bearing A 8 and bearing B 9 in the Ⅰ / Ⅲ quadrant shall be carried out according to the following steps:

[0057] ①First, assemble the inner ring 81 of bearing A and the shaft sleeve A11, such as Figure 4 shown;

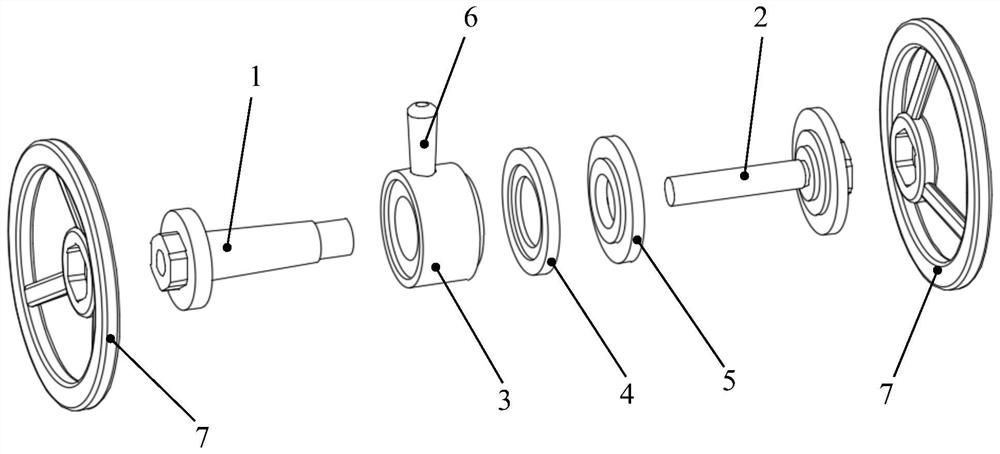

[0058] Put the big end of the shaft sleeve A11 downward on the outer tapered surface of the guide sleeve 1, and the taper direction of the two should be consistent; put the inner ring 81 of the bearing A on the outside of the shaft sleeve A11; place an adapter ring 3 on the On the end face of the inner ring 81 of bearing A, screw the guide rod 2 through the pressure ring 3 into the threaded hole of the guide sleeve 1, the positioning step of the guide rod 2 is closely matched with the pressure ring 3, continue to tighten the guide rod 1, and the bearing A The inner ring 81 is automatically aligned, and inserted into the sleeve A11 a little;

[0059] Place a turntable 7 on the workbench stably with the big end facing down, insert the head of th...

Embodiment 2

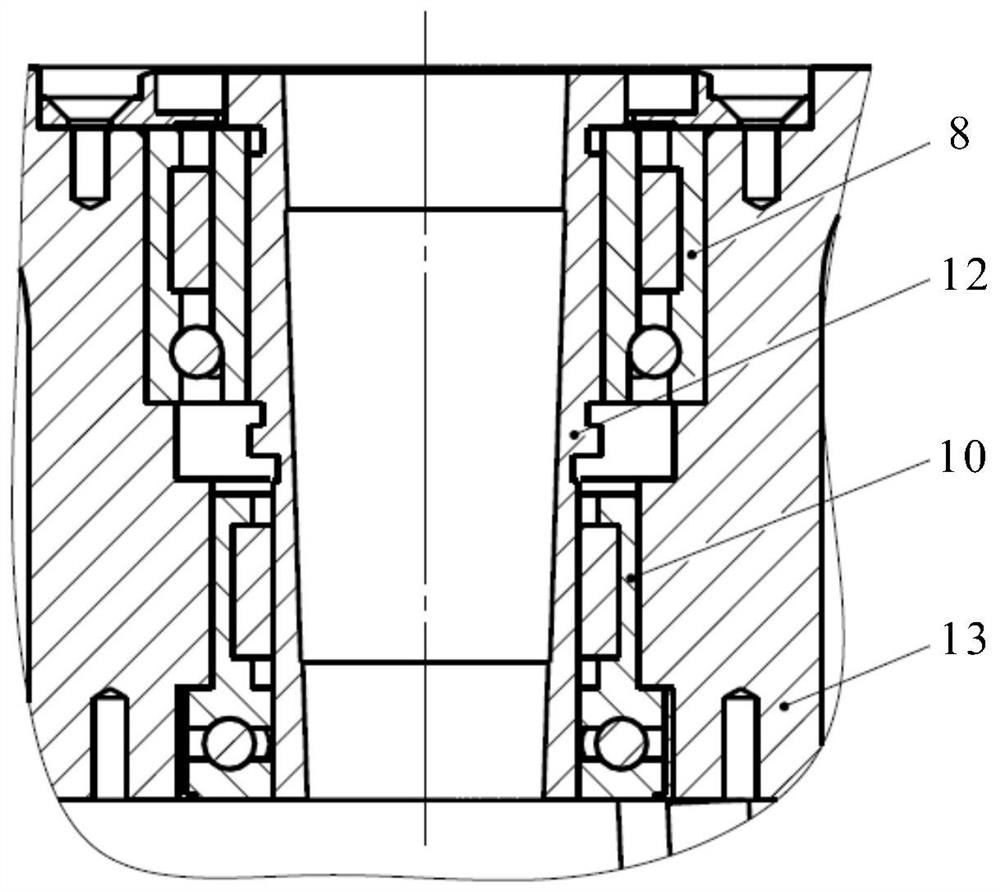

[0067] The assembly of bearing A8 and bearing C10 in quadrant Ⅱ / Ⅳ is carried out according to the following steps:

[0068] ① First, assemble the inner ring 81 of bearing A and the bushing B12, such as Figure 7 As shown, the assembly principle is the same as that of the bearing A inner ring 81 and the shaft sleeve A11 in Embodiment 1; the difference is that the placement direction of the bearing A inner ring 81 is different, and the placement direction is based on the II / IV quadrant of the cabin body 13 The installation direction of the bearing A 8 is determined.

[0069] ②Secondly, carry out the assembly of the outer ring 82 of the bearing A and the cabin body 13, such as Figure 8 As shown, the assembly principle is basically the same as the assembly of the bearing A outer ring 82 and the cabin body 13 in Embodiment 1; the difference is that the step of fitting the assembled bearing A inner ring 81 on the guide rod 2 is not included; Because of the small space inside the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com