Novel metal wire fused deposition processing mechanism and process

A technology of fused deposition and processing mechanism, applied in additive processing, additive manufacturing, etc., which can solve problems such as easy peeling, poor surface quality, and peeling between layers or lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

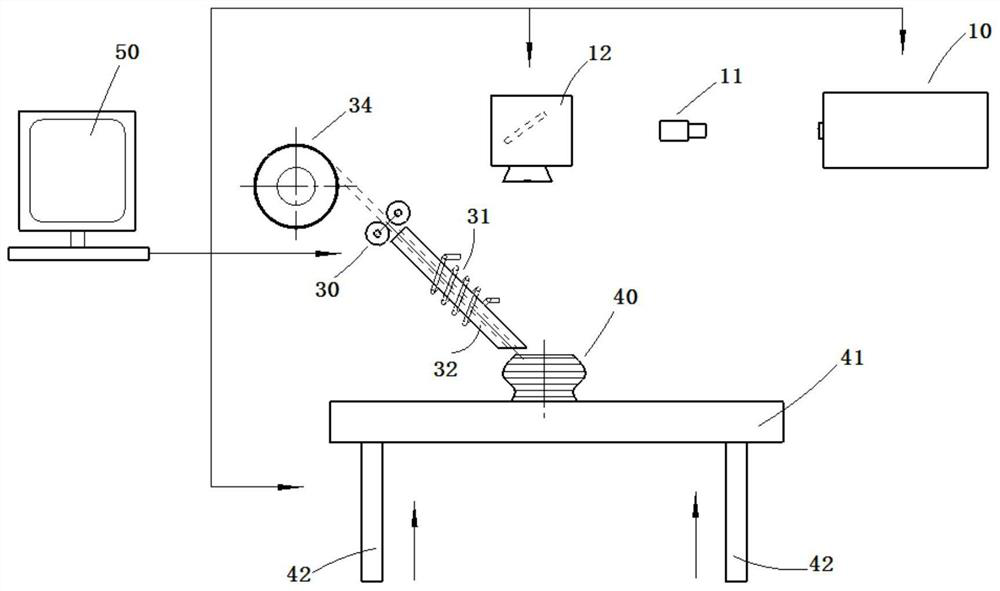

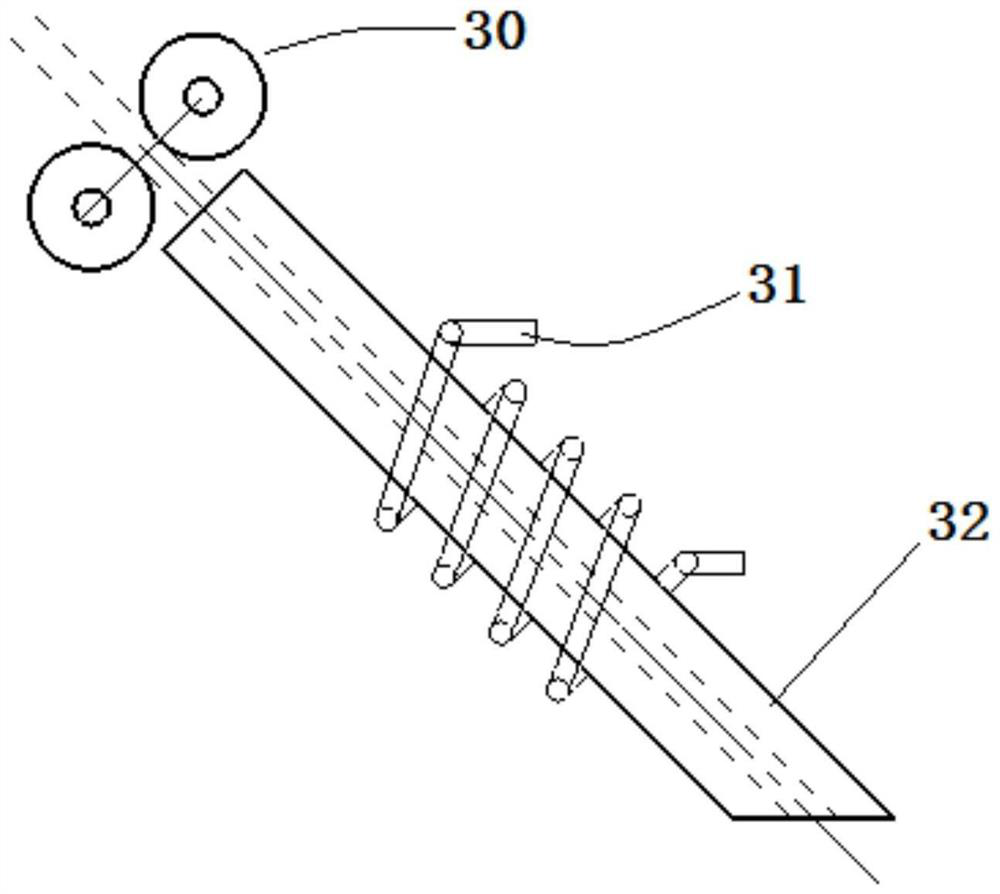

[0030] Embodiment 1: as Figure 1 to Figure 5 As shown, a new processing mechanism and process of metal wire fusion deposition includes a workbench 41, and the top of the workbench 41 is provided with an optical path system, a feeding mechanism and a control system.

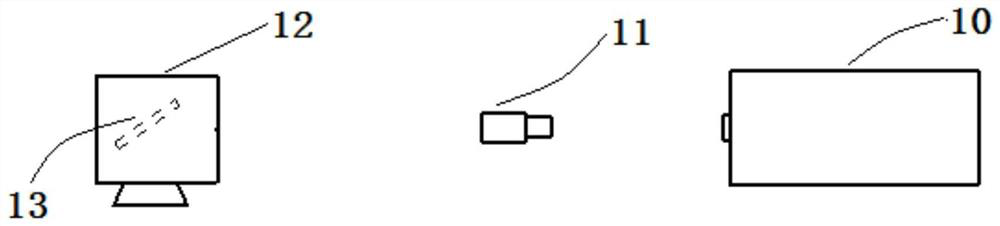

[0031] The optical path system includes: a laser 10, a beam expander 11, and a vibrating mirror 12. The vibrating mirror 12 is set above the workbench 41. The beam expander 11 is set on the side of the vibrating mirror 12. The laser 10 is set on the beam expander 11 away from the vibrating mirror 12. On one side, the control system is connected with the laser 10 and the vibrating mirror 12, and controls the laser 10 and the vibrating mirror 12. The workpiece 40 is arranged on the top of the workbench 41, and the workpiece 40 is located directly under the vibrating mirror 12.

[0032] The beam emitted by the laser 10 is expanded by the beam expander 11, then enters the vibrating mirror 12, is focused by the focusi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com