Medical waste cleaning treatment device

A technology of medical waste and treatment equipment, which is applied in the field of medical waste cleaning and treatment equipment, and can solve problems such as difficulties in waste treatment and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

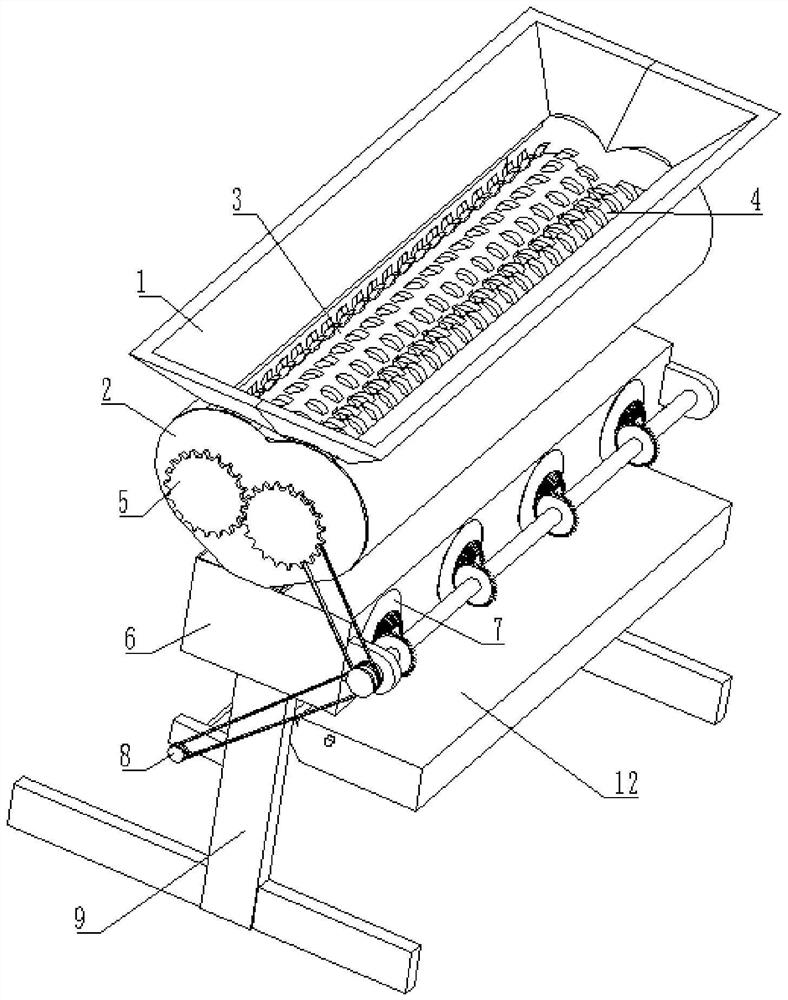

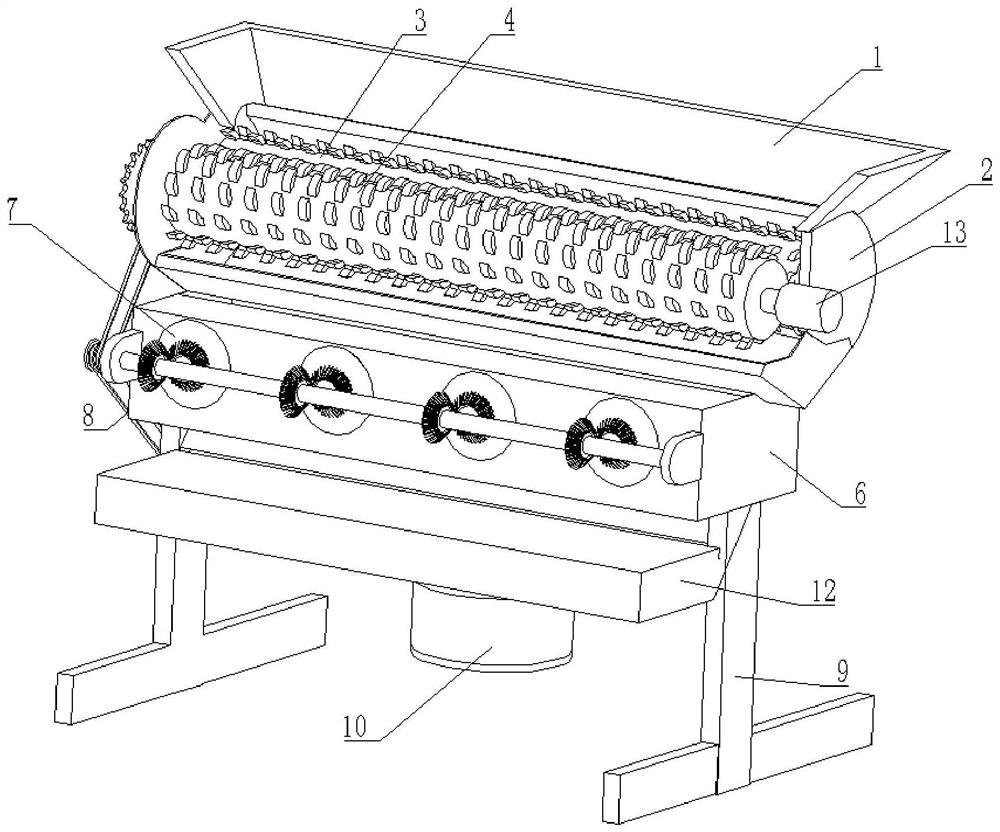

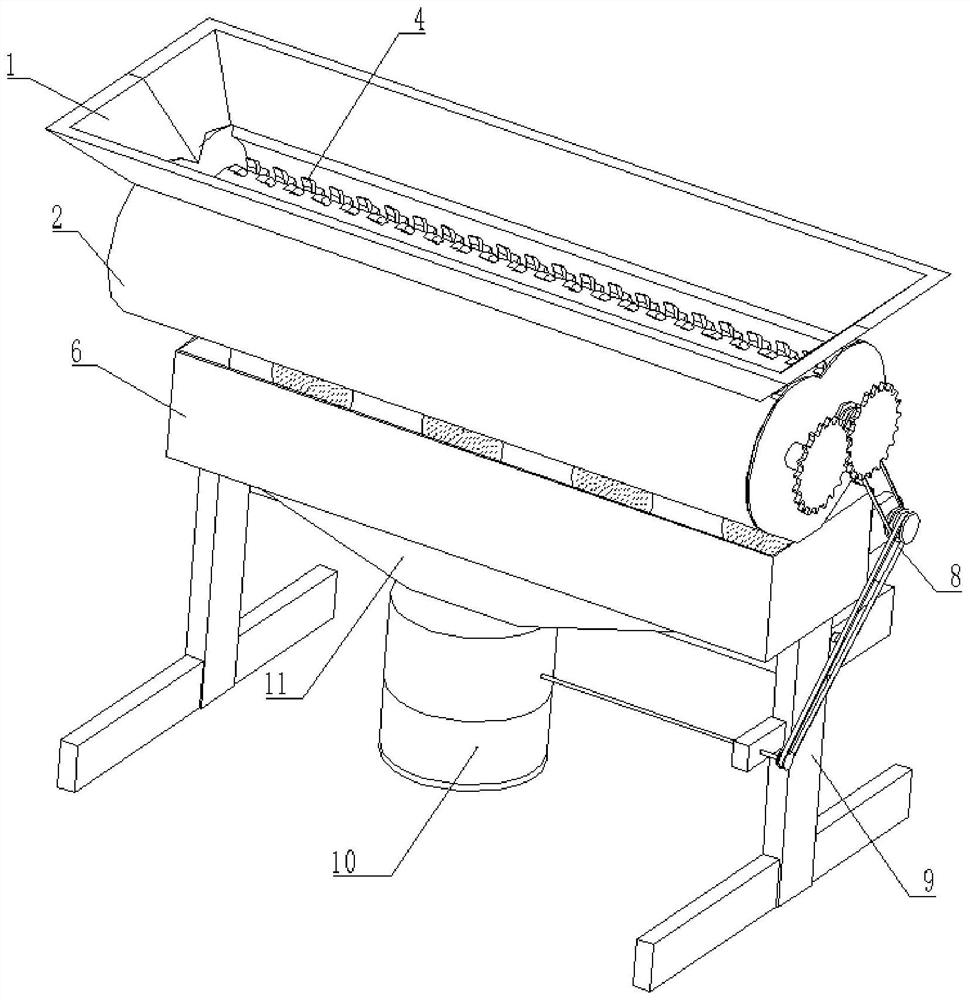

[0031] see Figure 1-6 , a medical waste cleaning treatment device, comprising a feed box 1, the bottom of the feed box 1 is welded with a treatment box 2, the inside of the treatment box 2 is respectively connected with a cutting roller 3 and a cutting roller 4, and the treatment box 2 The bottom of the frame 9 is fixedly connected with a separation box 6, the bottom of the separation box 6 is fixedly connected with a frame 9, the surface of the frame 9 is fixedly connected with a high temperature box 12, the surface of the frame 9 is provided with a transmission mechanism 8, and the inside of the separation box 6 is set There is a separation mechanism 7, the bottom of the separation box 6 is fixedly connected with a connecting pipe 11, the bottom of the connecting pipe 11 is provided with a disinfection mechanism 10, the right side of the processing box 2 is connected with a motor 13 by bolts, and the output end of the motor 13 is fixedly connected to the cutting machine. At...

Embodiment 2

[0039] see Figure 7-8 , on the basis of Embodiment 1, in the present embodiment, the transmission mechanism 8 includes a pulley one 81, the surface of the pulley one 81 is connected with the surface transmission of the double pulley 82 by a belt, and the surface of the double pulley 82 is connected by a belt and a pulley two 83 The surface transmission connection of the double belt pulley 82 is fixedly connected to the surface of the drive shaft 76, the axis of the belt pulley 81 is fixedly connected to the surface of the cutting roller 24, and the axis of the belt pulley 83 is fixedly connected to the transmission rod 84, the surface of transmission rod 84 is connected to the inside of frame 9 in rotation.

[0040] Through the connection and transmission of the pulley, the rotational force of the cutting roller is transmitted to the inside of the disinfection mechanism 10, reducing the use of the motor 13, thereby effectively reducing the cost and controlling the cost input....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com