Clamping device and method for testing fatigue performance of twisted steel bar

A threaded steel bar and clamping device technology, which is applied in the field of fatigue testing, can solve problems such as low success rate, threaded steel bar broken in the jaws, and inability to accurately measure the number of threaded steel fatigue damages, so as to avoid damage and fracture of threaded steel bar, improve The effect of success rate and accuracy, fast and efficient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A kind of method of testing threaded steel bar fatigue performance of embodiment one is realized by following steps:

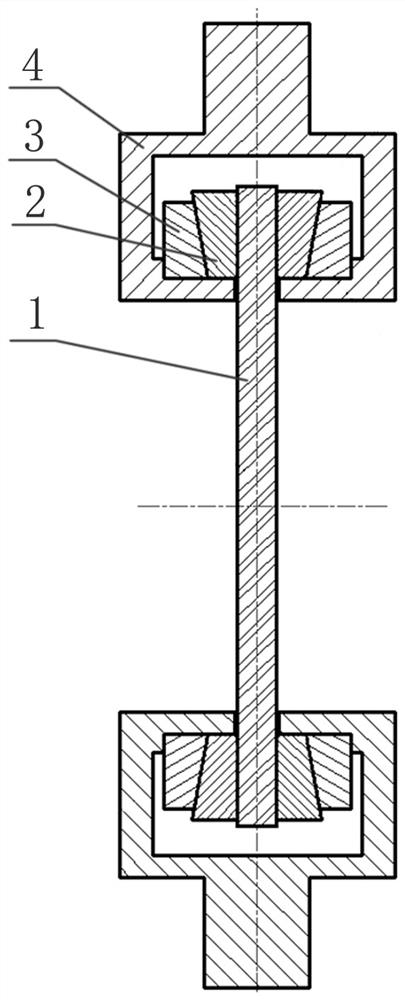

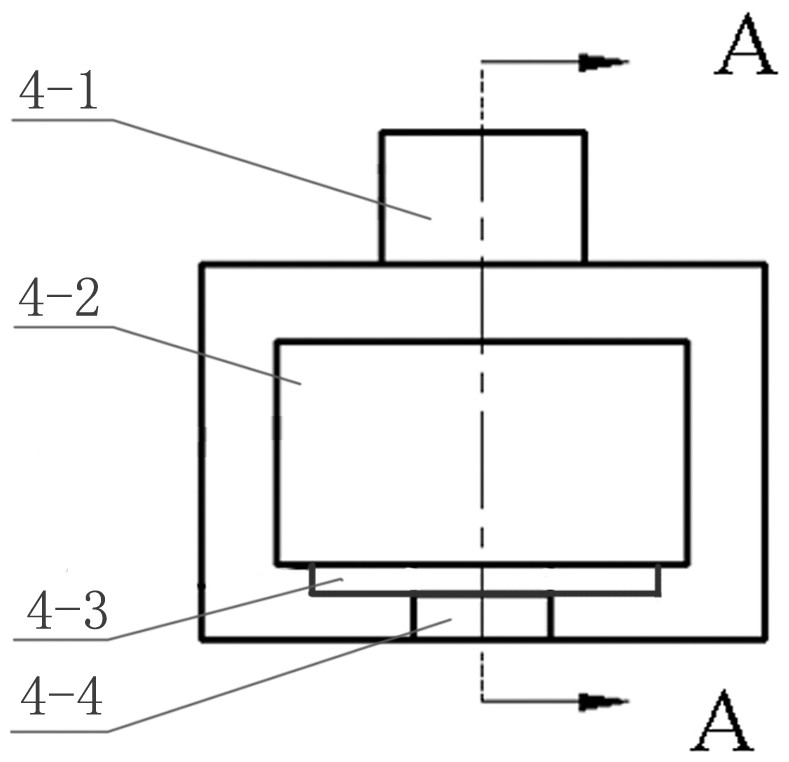

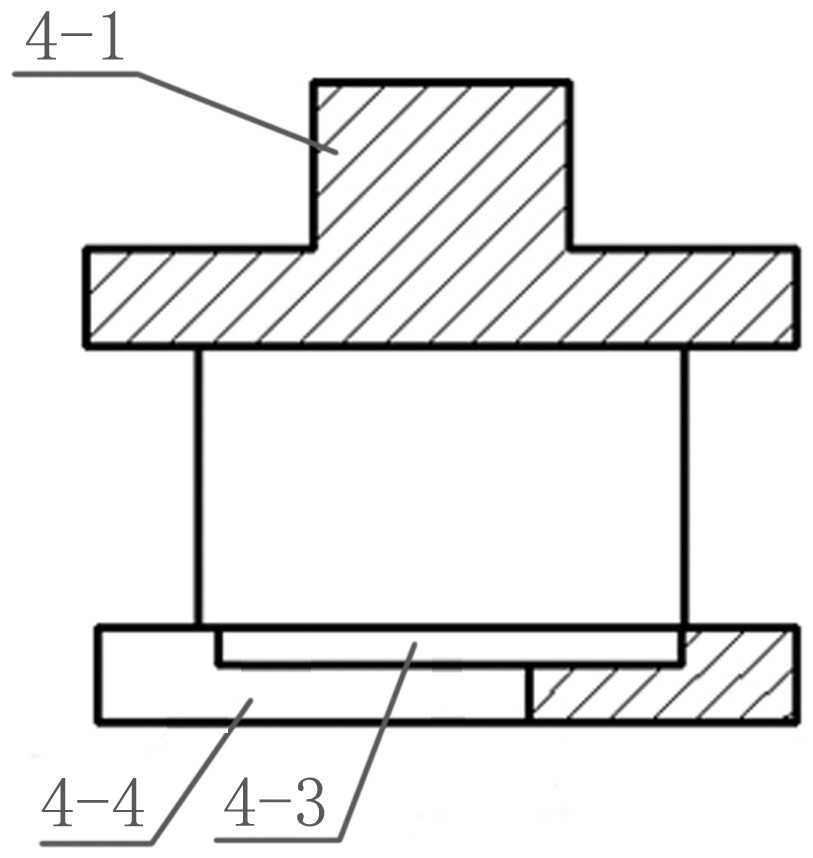

[0043] A. Select a threaded steel bar sample 1 with a designation of PSB830 and a nominal diameter of 15 mm, and select two sets of matching clips 2, tapered sleeves 3 and connectors 4 according to the diameter of the threaded steel bar sample 1;

[0044] B. According to the stroke of the fatigue testing machine and the length of the clamping device, the length of the threaded steel bar sample 1 is determined to be 1100mm, and the relative distance between the two connectors 4 is determined to be 800mm according to the length of the threaded steel bar sample 1 (that is, two The distance between the lower cavity wall of the connector 4);

[0045] C. Start the fatigue testing machine, so that the upper and lower jaws of the fatigue testing machine respectively clamp the clamping ends 4-1 of the two connectors 4, and the two connectors 4 are symmetrically ...

Embodiment 2

[0051] A kind of method of testing threaded steel bar fatigue performance of embodiment two is realized by following steps:

[0052] A. Select a threaded steel bar sample 1 with a designation of PSB830 and a nominal diameter of 32 mm, and select two sets of matching clips 2, tapered sleeves 3 and connectors 4 according to the diameter of the threaded steel bar sample 1;

[0053] B. According to the stroke of the fatigue testing machine and the length of the clamping device, the length of the threaded steel bar sample 1 is determined to be 1200mm, and the relative distance between the two connectors 4 is determined to be 900mm according to the length of the threaded steel bar sample 1 (that is, two The distance between the lower cavity wall of the connector 4);

[0054] C. Start the fatigue testing machine, so that the upper and lower jaws of the fatigue testing machine respectively clamp the clamping ends 4-1 of the two connectors 4, and the two connectors 4 are symmetrically ...

Embodiment 3

[0060] A kind of method of testing threaded steel bar fatigue performance of embodiment three is realized by following steps:

[0061] A. Select a threaded steel bar sample 1 with a designation of PSB830 and a nominal diameter of 75 mm, and select two sets of matching clips 2, tapered sleeves 3 and connectors 4 according to the diameter of the threaded steel bar sample 1;

[0062] B. According to the stroke of the fatigue testing machine and the length of the clamping device, the length of the threaded steel bar sample 1 is determined to be 1100mm, and the relative distance between the two connectors 4 is determined to be 800mm according to the length of the threaded steel bar sample 1 (that is, two The distance between the lower cavity wall of the connector 4);

[0063] C. Start the fatigue testing machine, so that the upper and lower jaws of the fatigue testing machine respectively clamp the clamping ends 4-1 of the two connectors 4, and the two connectors 4 are symmetricall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com