Method for improving cooling effect of generator outgoing line sleeve

A technology of outlet bushing and cooling effect, which is used in the testing of machine/structural components, fluid tightness testing, and by measuring the acceleration and deceleration rate of fluids, etc., can solve problems such as hydrogen leakage, improve air tightness, reduce Cost consumption and the effect of improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

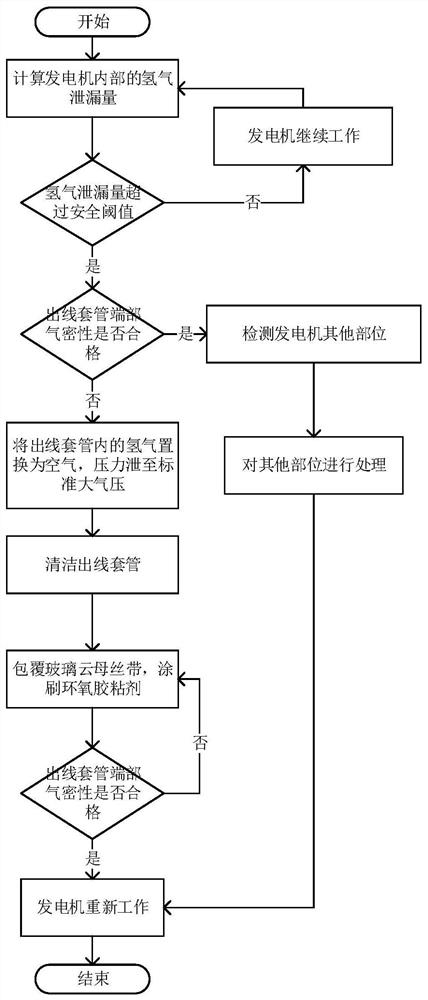

[0036] After the No. 3 generator of our factory was put into use, the total power generation increased, but with the increase of the generator's service time, the power generation efficiency of the generator gradually decreased. After investigation, it was found that apart from the decline in generator efficiency caused by component life issues, there were still factors that caused the generator's power generation efficiency to decline. After another investigation, it was found that the cooling effect of the generator outlet bushing of phase A of the No. 3 generator decreased, which led to a decrease in the generator's power generation efficiency.

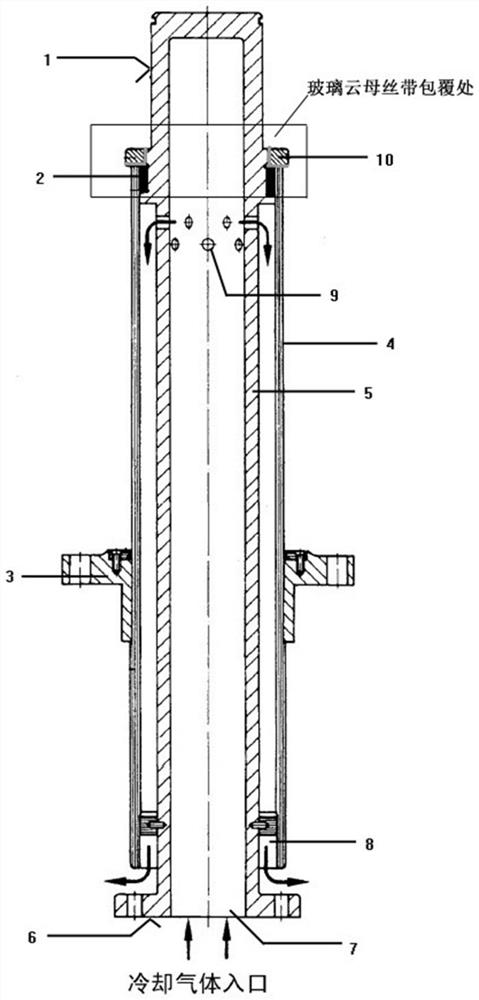

[0037] Such as figure 2 As shown, the outlet sleeve includes an outlet sleeve end joint 1, a rubber gasket 2, a mounting flange 3, an insulating sleeve 4, a tubular conductor 5, a generator side connecting flange 6, and an end fixing cover 10. The generator outlet bushing is fixed on the generator by the mounting flange 3, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com