Full-automatic high-safety low-nitrogen hot air heating combustion system and operation method thereof

A high-safety combustion system technology, applied in the direction of air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problem of not being able to reach the temperature of the self-ignition point, so as to avoid excessive fuel supply, good energy saving effect, and ensure no The effect of the leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with drawings and embodiments.

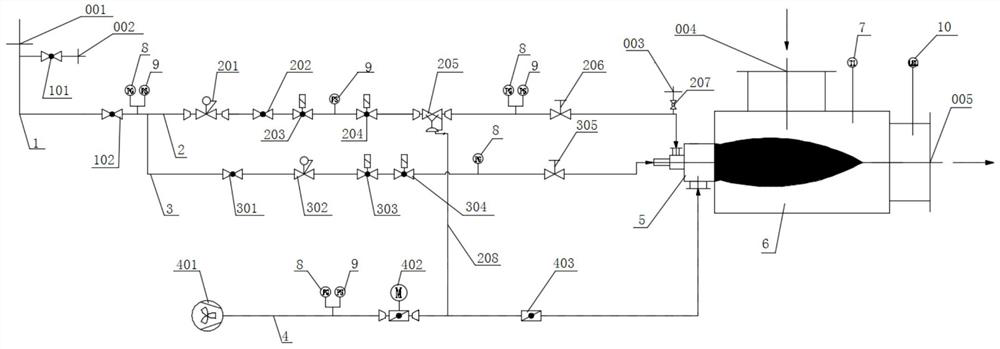

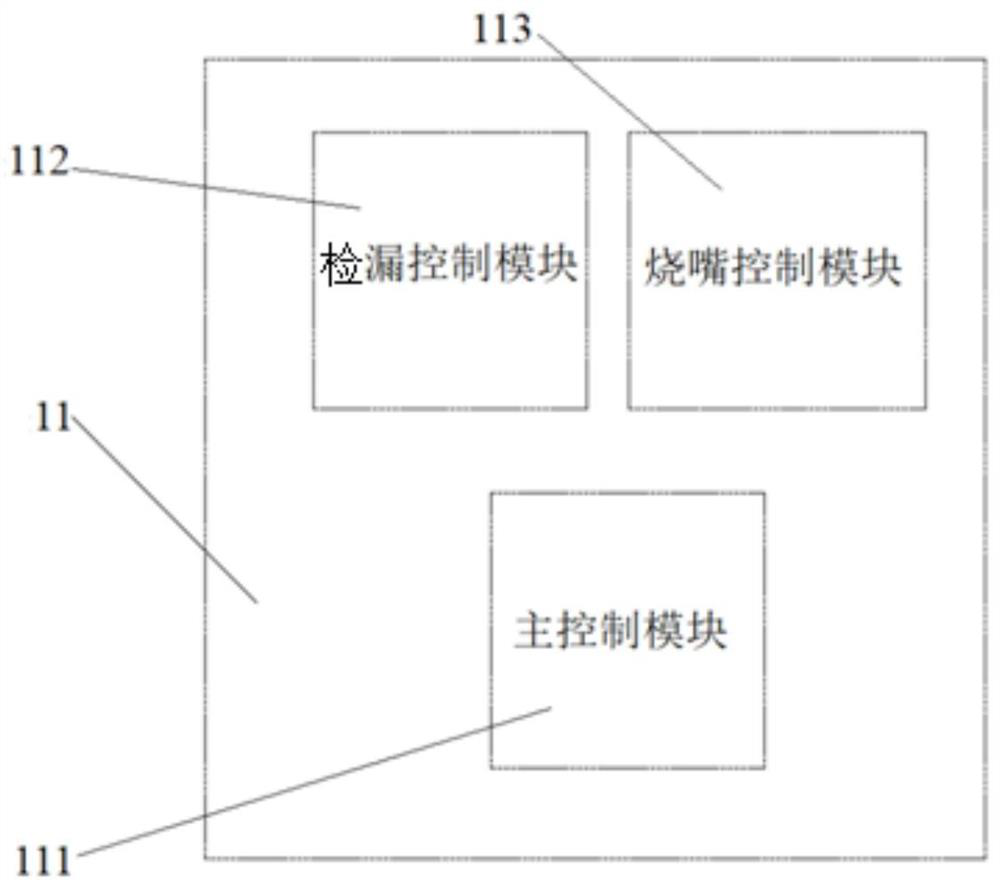

[0031] Such as figure 1 As shown, a fully automatic high-safety low-nitrogen hot air heating combustion system includes a hot blast stove 6, a main gas pipeline 1, a combustion-supporting air pipeline 4 and a controller 11, and the hot blast stove 6 is equipped with a flame automatic detection function Automatic ignition low-nitrogen burner 5, the entrance of the main gas pipeline 1 is the main gas inlet 001, the outlet is divided into the main gas pipeline 2 and the ignition gas pipeline 3, the entrance of the combustion air pipeline 4 is connected to the combustion air blower 401, the main gas The outlets of pipeline 2, ignition gas pipeline 3 and combustion-supporting air pipeline 4 are respectively connected to corresponding interfaces of automatic ignition low-nitrogen burner 5, and thermocouple 7 and combustible component detector 10 are arranged on the outlet sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com