Method for testing mechanical property of inert gas closed cycle radial flow type impeller

A closed cycle, inert gas technology, applied in the direction of mechanical equipment, non-variable pumps, engine components, etc., can solve the problems that the influence factors cannot be considered, and the accuracy of the aerodynamic characteristics of the impeller machinery cannot be guaranteed, so as to reduce the cost of performance tests , Reduce the cost of test construction and modification, and reduce the complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

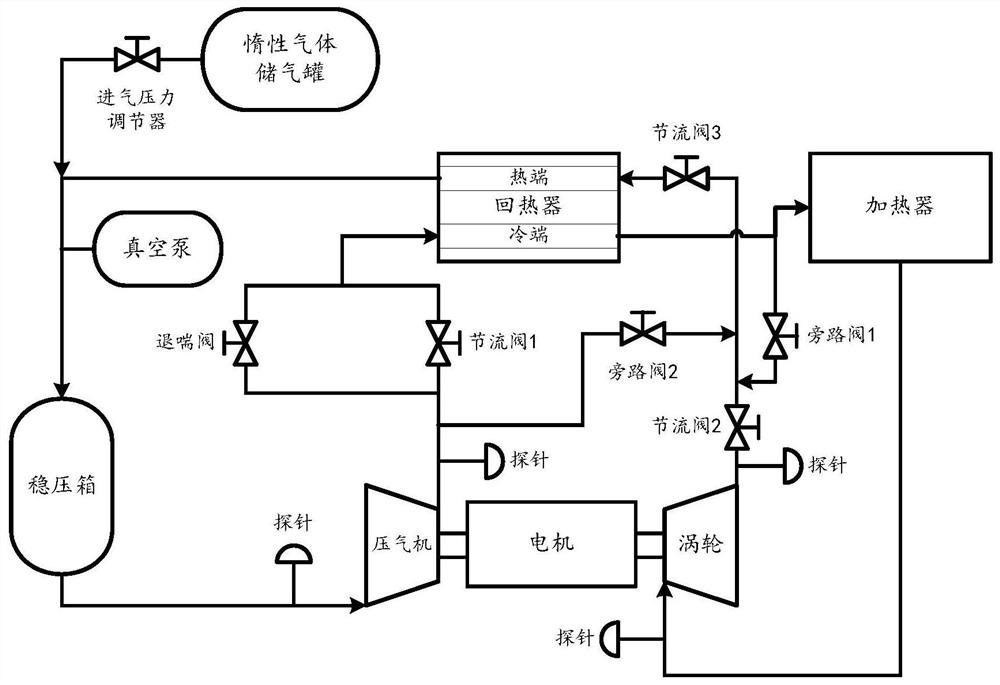

[0018] The mechanical performance test method of the inert gas closed circulation radial flow impeller of the present invention is based on figure 1 The shown inert gas closed circulation radial flow impeller mechanical performance test device is completed. The test device includes an inert gas storage tank, a surge tank, a centrifugal compressor, an exhaust valve, a throttle valve 1, a bypass valve 2, a regenerator, a heater, a centripetal turbine, a throttle valve 2, and a throttle valve 3. Bypass valve 1. Vacuum pump, motor; the inert gas storage tank is connected to the connecting pipeline between the surge tank and the regenerator to provide working fluid for the closed loop, and one end of the surge tank is connected to the upstream of the centrifugal compressor , the centrifugal compressor is coaxially connected to the motor, the motor is coaxially connected to the centripetal turbine, the upstream of the centripetal turbine is connected to the heater, the downstream of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com