A kind of anti-sticking ice coating for mine car and preparation method thereof

An anti-sticking and mine car technology, applied in the direction of coating, etc., can solve the problems of poor surface mechanical properties, loss of anti-icing effect, low surface tension, etc., achieve best adhesion and scratch resistance, and reduce ice adhesion Strength, anti-blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

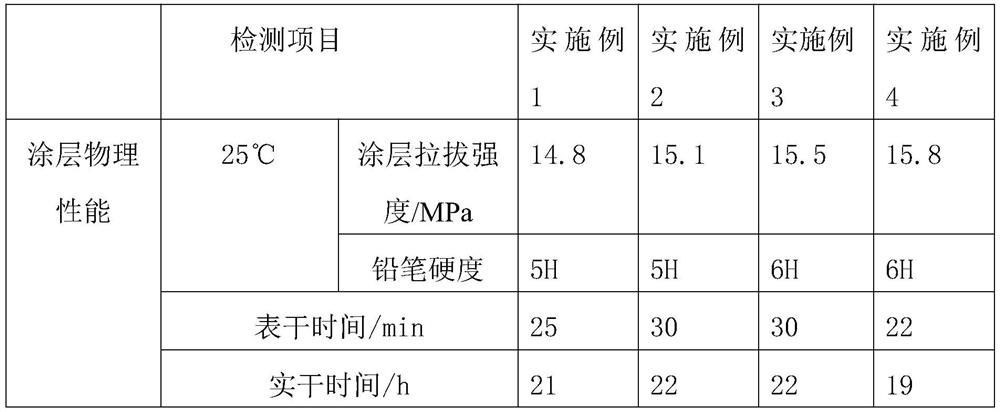

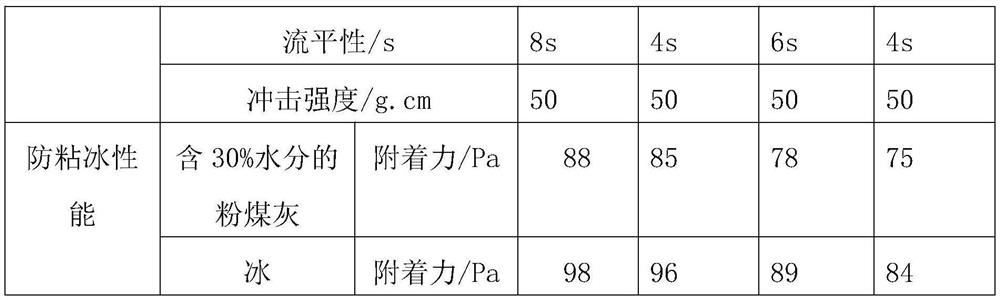

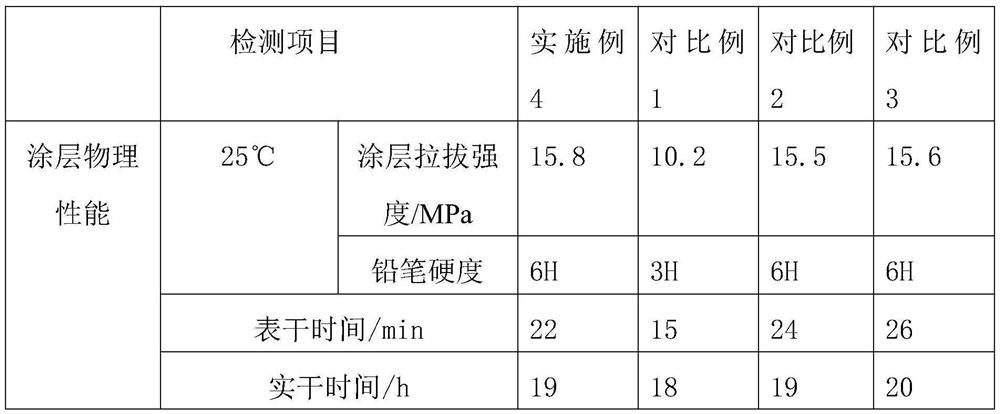

Examples

preparation example Construction

[0066] ① Preparation of silanol solution:

[0067] In parts by weight, 12-18 parts of methyl chlorosilane and 8-12 parts of phenyl chlorosilane are cooled to 0-5°C, 25-30 parts of toluene are added and evacuated into the batching tank, and the temperature of the batching tank is controlled to 0-5 ℃, stirring and mixing for 0.5 to 1 hour to obtain a premix;

[0068] Add 8~12 parts of water, 15~25 parts of toluene, 25~35 parts of acetone successively to the hydrolysis tank, stir for 20~30 minutes and lower the temperature to below 15°C, drop the premix into it, and control the temperature of the hydrolysis tank to be below 15°C. 15~25 ℃, stir and stand still for 10~15 minutes after the dropwise addition, release the acid in the hydrolyzate, wash with water until the pH of the solution is 5~7, to obtain a silanol solution;

[0069] ② Preparation of epoxy modified silicone resin:

[0070] The silanol solution obtained in step 1. is pumped to a dissolving tank, the temperature is...

Embodiment 1

[0127] An anti-stick ice coating for mining trucks is composed of A component and B component; wherein A component is composed of the following raw materials: 20kg of epoxy modified silicone resin, 25kg of functional filler, 0.5kg of dispersant, wetting agent 0.1kg, active leveling agent 1kg, adhesion promoter 0.1kg, defoamer 0.1kg, rheology aid 0.1kg, anti-scratch aid 0.4kg and first solvent 20kg; component B consists of the following raw materials: 9kg of crosslinking agent and 2kg of second solvent;

[0128] The epoxy modified silicone resin is prepared according to the following steps:

[0129] ① Preparation of silanol solution:

[0130] 24kg methyl chlorosilane and 16kg phenyl chlorosilane are cooled to 0~5 ℃, add 50kg toluene and vacuum pump into the batching tank, control the batching tank temperature 0~5 ℃, stir and mix for 0.5 hour, obtain the premix;

[0131] In the hydrolysis tank, add 16kg water, 30kg toluene, 50kg acetone successively, stir for 20~30 minutes and...

Embodiment 2

[0146] An anti-stick ice coating for mining trucks is composed of component A and component B; wherein component A is composed of the following raw materials: 30 kg of epoxy modified silicone resin, 30 kg of functional filler, 1 kg of dispersant, and 0.5 kg of wetting agent. kg, active leveling agent 2kg, adhesion promoter 0.8kg, defoamer 0.5kg, rheology aid 0.5kg, anti-scratch aid 1kg and first solvent 25kg; component B consists of the following raw materials: cross-linking 12kg of agent and 5kg of second solvent;

[0147] The epoxy modified silicone resin is prepared according to the following steps:

[0148] ① Preparation of silanol solution:

[0149] 36kg methyl chlorosilane and 24kg phenyl chlorosilane are cooled to 0~5 ℃, add 60kg toluene and vacuum pump into the batching tank, control the batching tank temperature 0~5 ℃, stir and mix for 1 hour, obtain the premix;

[0150] In the hydrolysis tank, add 24kg water, 50kg toluene, 70kg acetone successively, stir for 30 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com