An aggregate transfer mechanism for an anti-drift chain

An anti-drifting and aggregating technology, applied in conveyors, loading/unloading, conveyor objects, etc., to achieve the effect of convenient use, improved service life and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

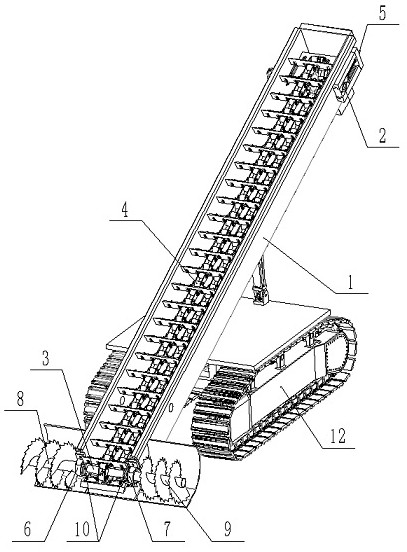

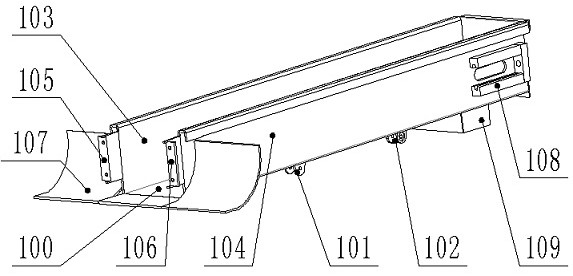

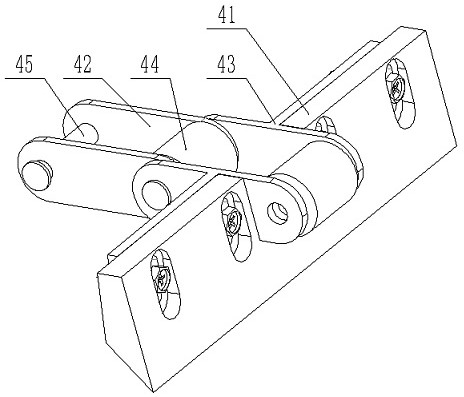

[0016] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, an aggregate transfer mechanism for an anti-drifting chain includes a tank body 1, a driving sprocket assembly 2, a tensioning device 5, a driven sprocket shaft 3, an anti-drifting scraper chain 4, a left support seat 6, and a right support Seat 7, left helical blade shaft 8, right helical blade shaft 9 and coupling 10; wherein, groove body 1 consists of bottom plate 100, front hinged ear seat 101, rear hinged ear seat 102, left side plate 103, right side plate 104. The left support plate 105, the right support plate 106, the shovel plate 107, the slip slot 108 and the discharge port 109 are composed; the left support seat 6 and the right support seat 7 are respectively fixed on the left support plate on both sides of the front end of the tank body 1 105 and the right support plate 106; the left helical blade shaft 8 and the right helical blade shaft 9 are fixedly connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com