Fastening device suitable for welding of different hardware pipe fittings

A pipe fitting welding and fastening device technology, which is applied in welding equipment, auxiliary equipment, welding equipment, etc., can solve the problems of manual welding without protective measures, difficulty in ensuring weld quality, and increased use costs, so as to increase versatility, The effect of improving weld quality and reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

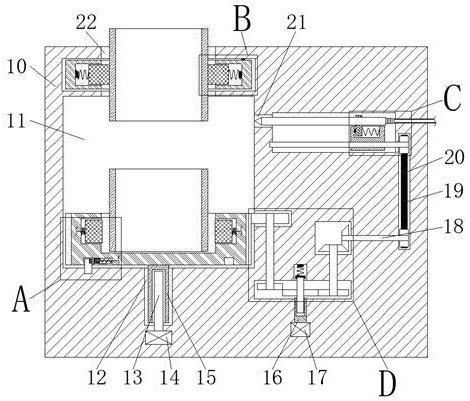

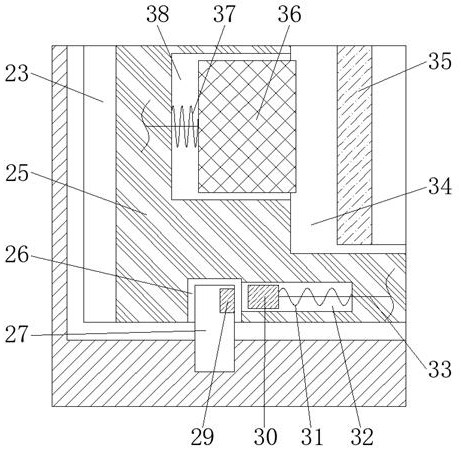

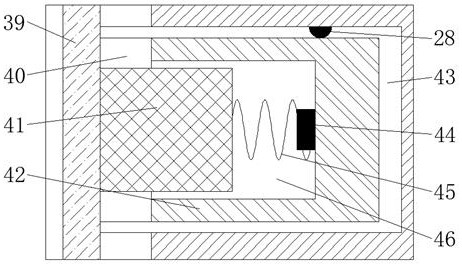

[0019] Combine below Figure 1-5 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0020] A fastening device suitable for welding different hardware pipe fittings described in conjunction with accompanying drawings 1-5, includes a main body box 10, a welding cavity 11 is provided inside the main body box 10, and a welding torch is connected to the right side of the welding cavity 11 Through cavity 21, the right side of the welding torch through cavity 21 is connected with a storage cavity 54, and the right side of the storage cavity 54 is provided with a power belt cavity 20, and the right end wall of the storage cavity 54 is rotationally fitted and connected and extends to the left. The reciprocating screw rod 52 in the left end wall of the storage cavity 54 and ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com