Pipe forging forming device with middle flange and side wall holes

A technology for pipes and flanges, which is applied in the field of pipe forging forming devices, can solve the problems of time-consuming and laborious, long processing time and low degree of automation, and achieve the effects of reducing production costs, reducing process procedures, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Specific examples are given below to further describe the technical solution of the present invention in a clear, complete and detailed manner. This embodiment is the best embodiment on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments.

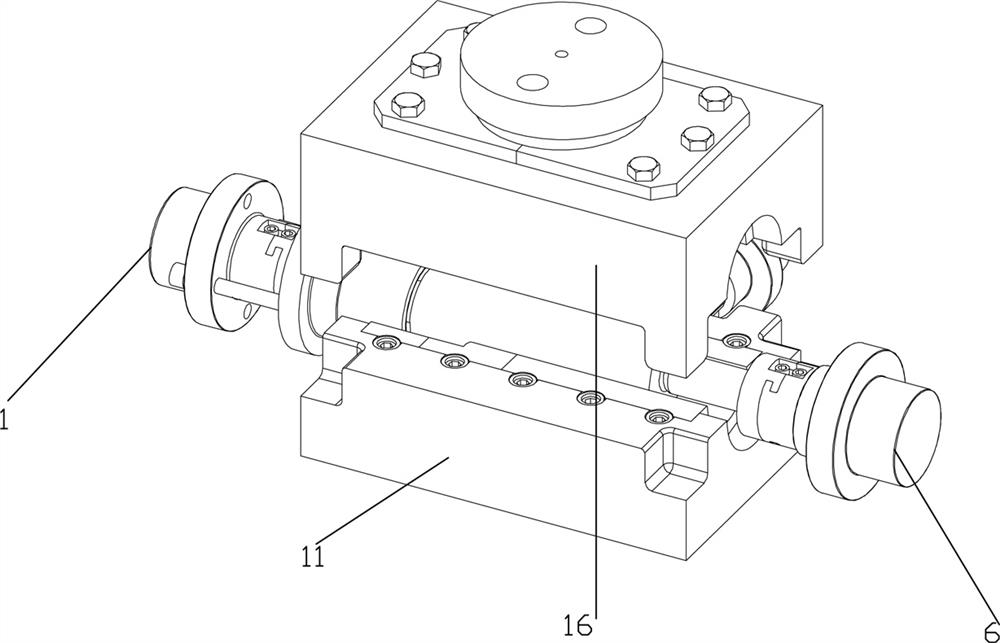

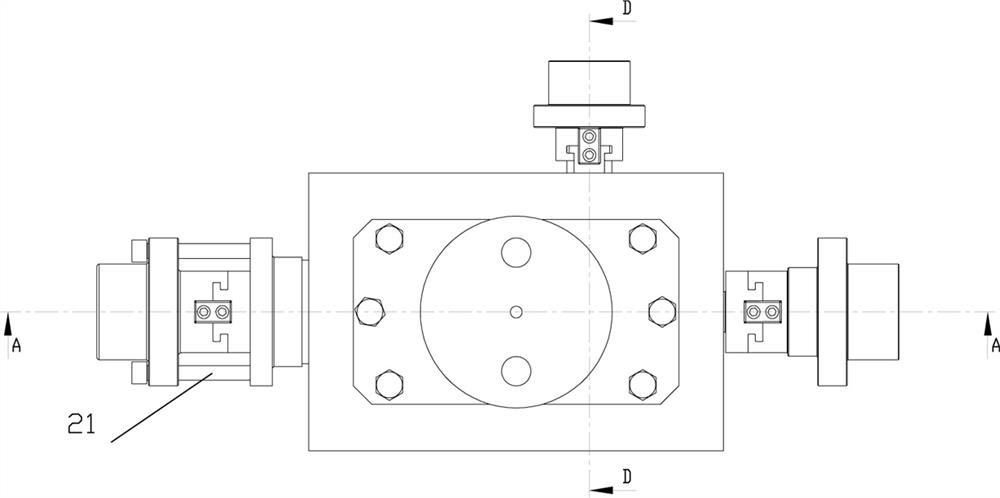

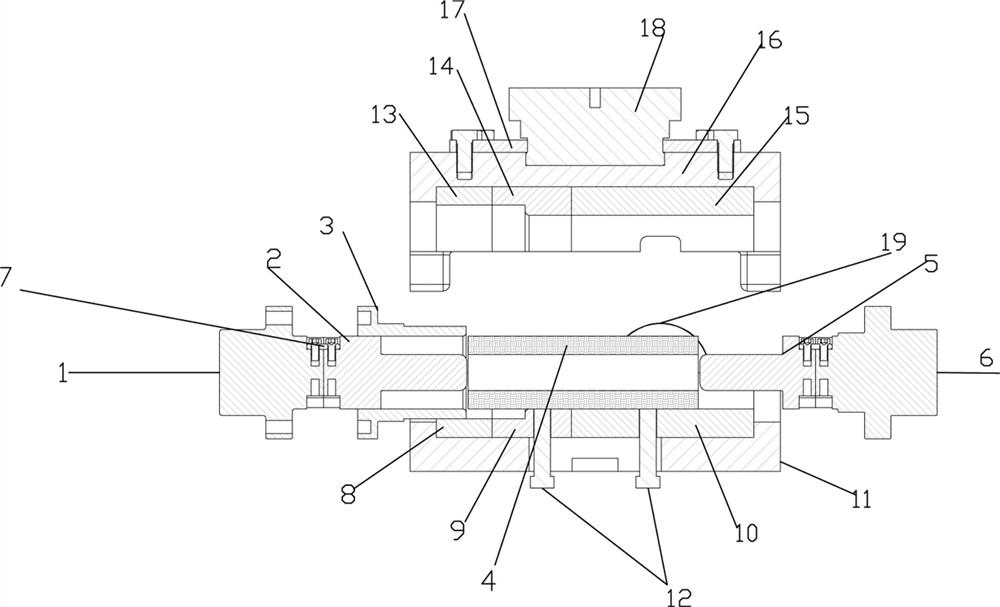

[0033] A pipe forging forming device with a central flange and side wall holes, comprising a pipe material 4, a push rod 12, and an upper die assembly, a lower concave die assembly, and a lower concave die assembly respectively located on the upper, lower, left, right, and rear sides of the pipe material 4. Die assembly, left punch 2, right punch 5, rear blanking assembly, the upper die assembly and the lower die assembly are symmetrically distributed with the middle horizontal section of the pipe material 4 as the symmetrical plane, and the rear The centerline of the blanking assembly is perpendicular to the centerline of the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com