System for synergistically removing flue gas fine particles and sulfur trioxide from desulfurization wastewater

A desulfurization wastewater and removal technology, applied in the fields of dispersed particle filtration, gaseous discharge wastewater treatment, water/sewage treatment, etc., can solve the problems of strong corrosiveness, high turbidity, and excessive heavy metal content in desulfurization wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]In order to make it possible to understand the invention, the advantages of the present invention will be more obvious and easy to understand, and the technical solutions in the embodiments of the present invention will be clear and completely, clearly, the embodiments described below are merely implemented Example, not all embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

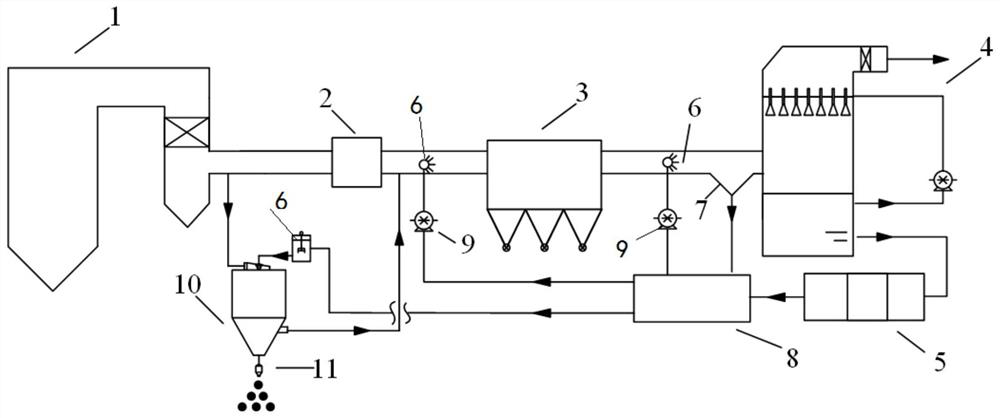

[0027]Seefigure 1, A schematic diagram of a system of a desulfurization wastewater association with a desulfurization wastewater coordinating to remove smoke particles and sulfur dioxide.

[0028]The present invention provides an embodiment of a system of desulfurization wastewater coordinating deprinted flue gas fine particles and sulfur dioxide, including: in turn, coal-fired boiler 1, SCR denitration apparatus, dust collector 3, wet desulfurization device 4, Tri / box 5 and solid-liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com