Drug-loaded microsphere and preparation method thereof

A technology of drug-loaded microspheres and microspheres, which is applied in the direction of pharmaceutical formulations, medical preparations with non-active ingredients, and medical preparations containing active ingredients, etc., which can solve problems such as high production costs, cumbersome procedures, and increased production costs. Achieve good physical and chemical properties, reduce preparation procedures, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This example discloses the preparation of ultra-high-loaded polypeptide, protein microspheres, and spermine-modified acetalized dextran (AcDX-SP)-coated insulin (INS) microspheres (INS@AcDX-SP).

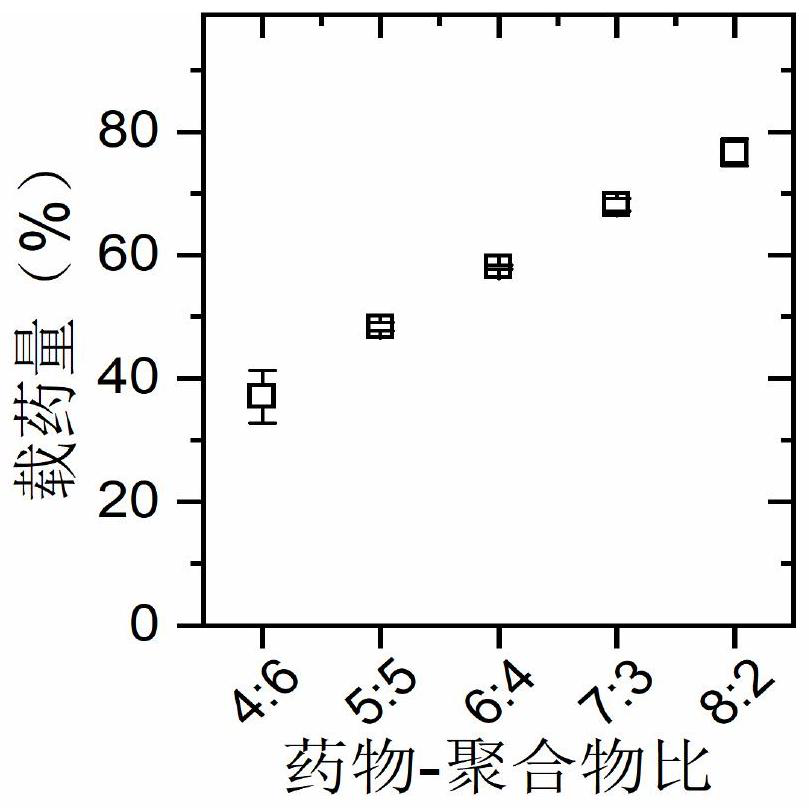

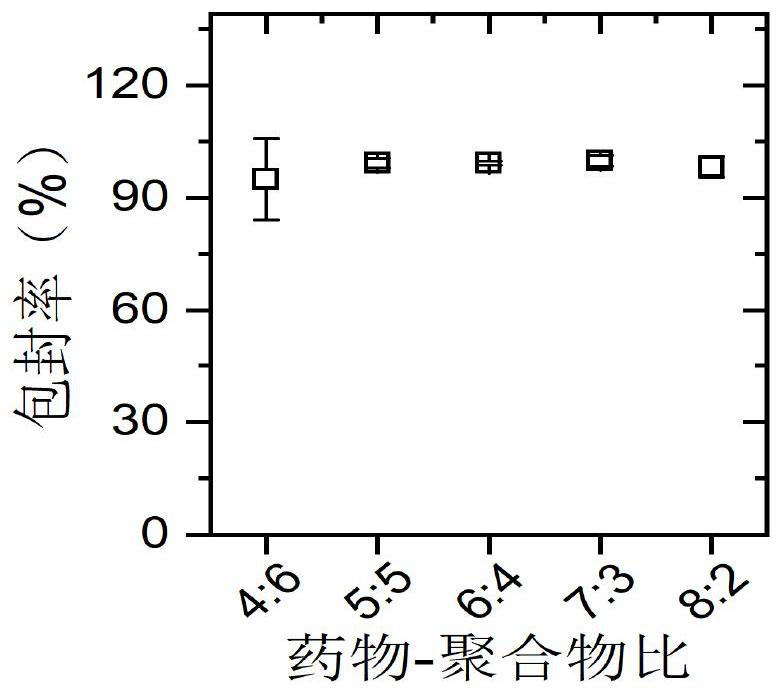

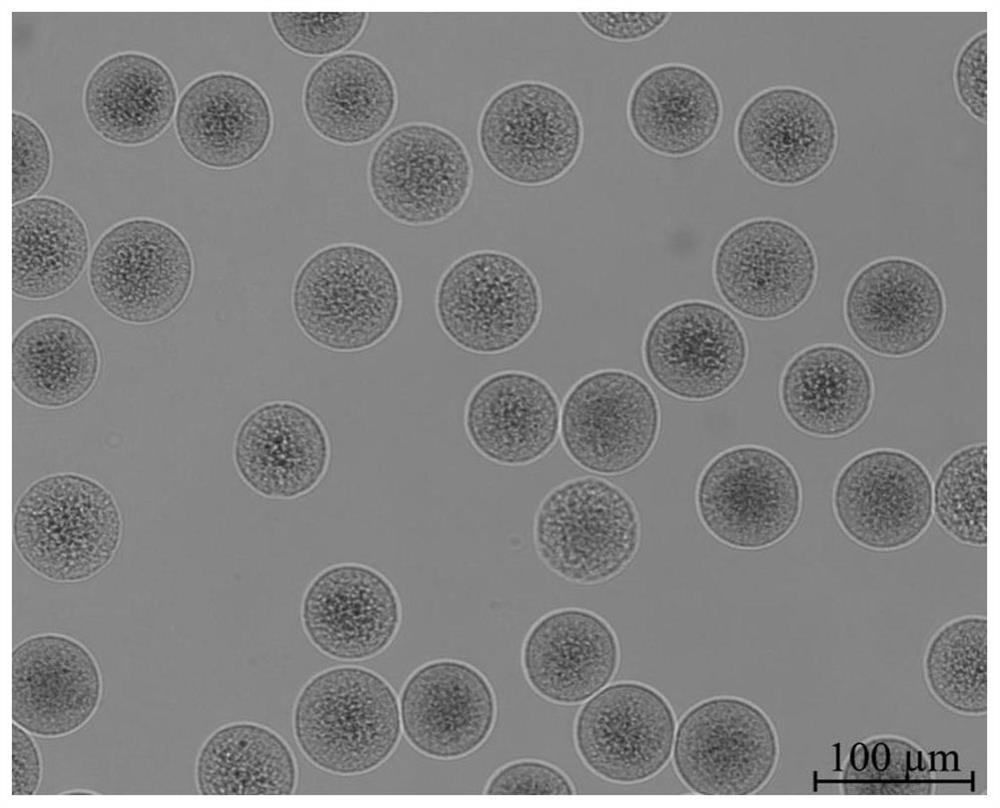

[0049] Acetone and INS (20 mg / mL) hydrochloric acid solution were used as the first reactant and the second reactant respectively, and INS nanoparticles were formed under stirring conditions. AcDX-SP dimethyl carbonate solution and 1% povidone (PVA) solution were used as the third reactant and the fourth reactant respectively. The oil-in-water emulsion is prepared by a microfluidic device and solidified by a solvent extraction method to obtain microspheres. A series of microspheres were obtained by adjusting the feeding ratio of INS and framework materials, with an average particle size of 35-65 μm and a drug loading of 37.0-76.6% ( figure 1 ), the encapsulation efficiency is 95.0-99.9% ( figure 2 ).

Embodiment 2

[0051] This example discloses the preparation of ultra-high-loaded polypeptide and protein microspheres, AcDX-SP-coated bovine serum albumin (BSA) microspheres (BSA@AcDX-SP).

[0052] Acetonitrile and BSA (20 mg / mL) aqueous solution were used as the first reactant and the second reactant respectively, and BSA nanoparticles were formed under stirring conditions. AcDX-SP dimethyl carbonate solution and 1% povidone (PVA) solution were used as the third reactant and the fourth reactant respectively. The oil-in-water emulsion is prepared by a microfluidic device and solidified by a solvent extraction method to obtain microspheres. A series of microspheres were obtained by adjusting the feeding ratio of BSA and the framework material, and the drug loading was 40.0-58.5% ( Figure 8 ), the encapsulation efficiency is 73.2-99.9% ( Figure 9 ).

Embodiment 3

[0054] This example discloses the preparation of ultra-high-loaded polypeptide and protein microspheres, AcDX-SP-wrapped β-lactoglobulin (β-LG) microspheres (β-LG@AcDX-SP).

[0055] An aqueous solution of tetrahydrofuran and β-LG (50 mg / mL) was used as the first reactant and the second reactant respectively, and β-LG nanoparticles were formed under stirring conditions. AcDX-SP dimethyl carbonate solution and 1% povidone (PVA) solution were used as the third reactant and the fourth reactant respectively. The oil-in-water emulsion is prepared by a microfluidic device and solidified by a solvent extraction method to obtain microspheres. A series of microspheres were obtained by adjusting the feeding ratio of β-LG and the framework material, and the drug loading was 39.3-61.1% ( Figure 15 ), the encapsulation efficiency is 51.4-100.0% ( Figure 16 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com