Phase change memory and manufacturing method thereof

A phase-change memory and phase-change memory technology, which is applied in semiconductor devices, electric solid-state devices, electrical components, etc., can solve the problems of low-quality phase-change memory, and achieve the effect of improving performance, yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

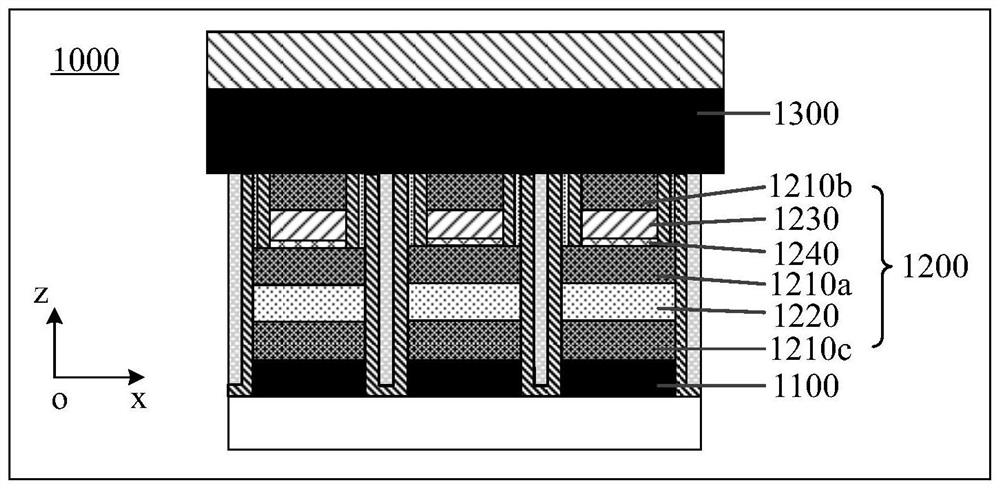

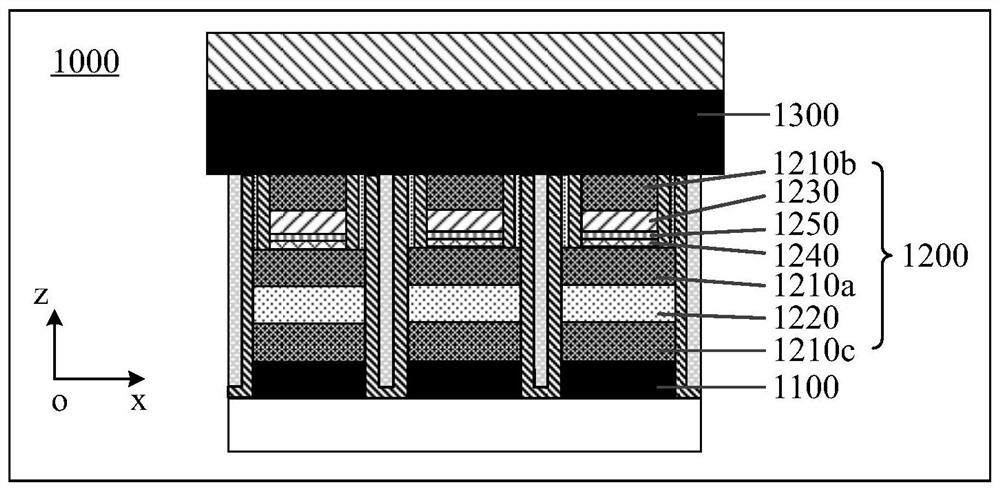

[0134] Figure 5a to Figure 5k It is a manufacturing method of a phase change memory shown according to an exemplary embodiment. refer to Figure 5a to Figure 5k , the method includes the following steps:

[0135] Step 1: Refer to Figure 5a As shown, a first conductive material layer 1110 and a storage stack structure are formed on the surface of the substrate 1001, and a first mask layer 1271 covering the storage stack structure is formed; wherein, the storage stack structure includes: a third layer stacked sequentially from bottom to top The first electrode material layer 1211c, the gate material layer 1221, the first electrode material layer 1211a, the first adhesive material layer 1241a, the phase change memory material layer 1231, the second adhesive material layer 1241b, and the second electrode material layer layer 1211b; the first adhesive material layer 1241a is used to increase the adhesion between the first electrode material layer 1211a and the phase change sto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com