Efficient mining method for coal bed gas short horizontal well group of broken low-permeability coal seam

A mining method and horizontal well technology, applied in the direction of mining fluid, drilling equipment and methods, directional drilling, etc., can solve the problems of difficult commercial promotion and poor drainage effect, and achieve the reduction of the number of well sites, the reduction of mining costs, Optimizing the effect of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

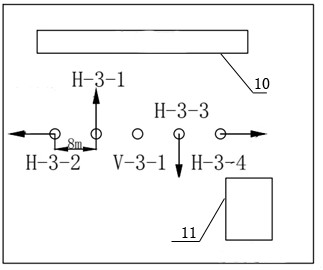

[0031] Such as figure 1 As shown, the naming method of short horizontal well group platform wells: such as "V-3-1": "V" indicates drainage and production vertical wells, "3" indicates the coal seam number, and "1" is the serial number. Arrange short horizontal wells at intervals of 8m to the left or right with the drainage well as the center, so that the horizontal projections of the wells do not intersect; anti-collision calculations and anti-collision measures should be made for the well location layout to avoid intersection of trajectories and ensure smooth construction and well boreholes whole. Short horizontal well number "H-3-1": "H" means horizontal well, "3" means coal seam number, and "1" means serial number. Marked as H-3-2, H-3-3, H-3-4 in sequence, well group drilling adopts the method of "cluster well layout, trajectory optimization control, resource optimization, and efficient construction" for construction management, shortening the drilling cycle and reducing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com